Method for preparing polyether imide copolymer by bisubstituted compound and bisphenol

A technology of polyetherimide copolymer and polyetherimide, which is applied in the field of preparing polyetherimide copolymers from double-substituted compounds and bisphenols, can solve the problems of low molecular weight, reduce production costs, and facilitate recycling The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

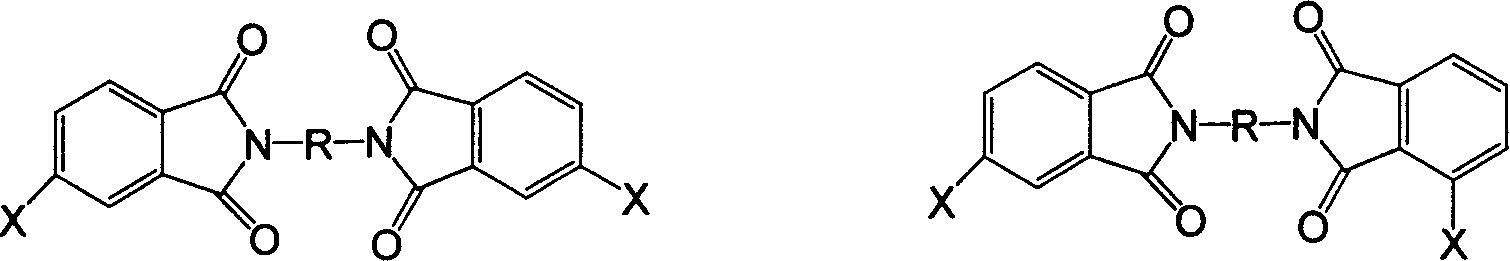

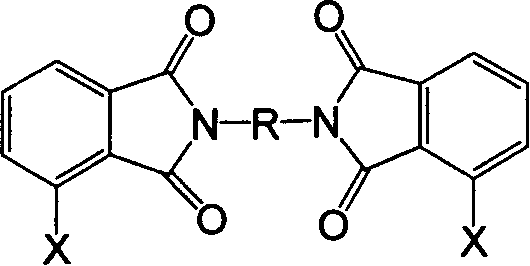

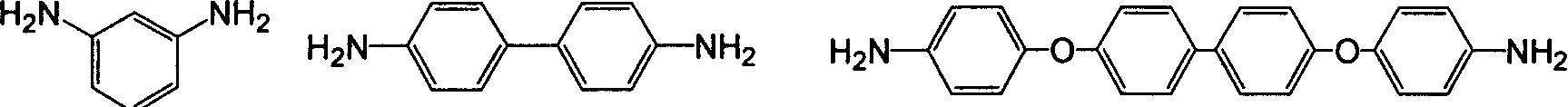

Method used

Image

Examples

Embodiment 1

[0038] Add 0.01 moles (2.28g) of bisphenol A, 14.7 grams of diphenylsulfone and 0.02 moles (2.0g) of 40% NaOH solution into a three-neck flask, pass nitrogen to remove oxygen, add 25 milliliters of xylene, and reflux with water for 2 hours Afterwards, add 0.009 mole (4.761g) of 4,4'-bis(4-chlorophthalimide) diphenyl ether, 0.001 mole (0.287g) of 4,4-dichlorodiphenyl sulfone, at 160 ℃ polymerization reaction for 20 hours. The resulting polymer solution was poured into 3% dilute hydrochloric acid in a thin stream, filtered and ground. The solvent was extracted with ethanol, and the intrinsic viscosity of the obtained polymer was 0.32dL / g.

Embodiment 2

[0040] Add 0.01 moles (2.28g) of bisphenol A, 45 grams of diphenyl sulfone and 0.02 moles (2.0g) of 40% NaOH solution into a three-neck flask, pass nitrogen to remove oxygen, add 40 milliliters of xylene, and reflux with water for 4 hours After that, add 0.009 mole (4.761g) of 4,4'-bis(4-chlorophthalimide) diphenyl ether, 0.001 mole (0.287g) of 4,4-dichlorodiphenyl sulfone at 300 ℃ polymerization reaction for 2 hours. The resulting polymer solution was poured into 3% dilute hydrochloric acid in a thin stream, filtered and ground. The solvent was extracted with acetone, and the intrinsic viscosity of the obtained polymer was 0.65dL / g.

Embodiment 3

[0042] Add 0.01 moles (2.28g) of bisphenol A, 45 grams of diphenyl sulfone and 0.02 moles (2.8g) of 40% KOH solution into a three-neck flask, pass nitrogen to remove oxygen, add 25 milliliters of xylene, and reflux with water for 4 hours Finally, add 0.009 mole (4.932g) of 4,4'-bis(4-nitrophthalimide) diphenyl ether, 0.001 mole (0.287g) of 4,4-dichlorodiphenyl sulfone, in Polymerization at 180°C for 200 hours. The obtained polymer solution was poured into 3% dilute hydrochloric acid in a trickle, filtered and ground. The solvent was extracted with acetone and ethanol, and the intrinsic viscosity of the obtained polymer was 0.47dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com