Centrifugal compressor shaft wearing repair method

A centrifugal compressor, wear repair technology, applied in coating, metal material coating process, melt spraying, etc., can solve problems such as bending deformation, internal cracks, etc., achieve good bonding force, energy saving and environmental protection, heat input Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

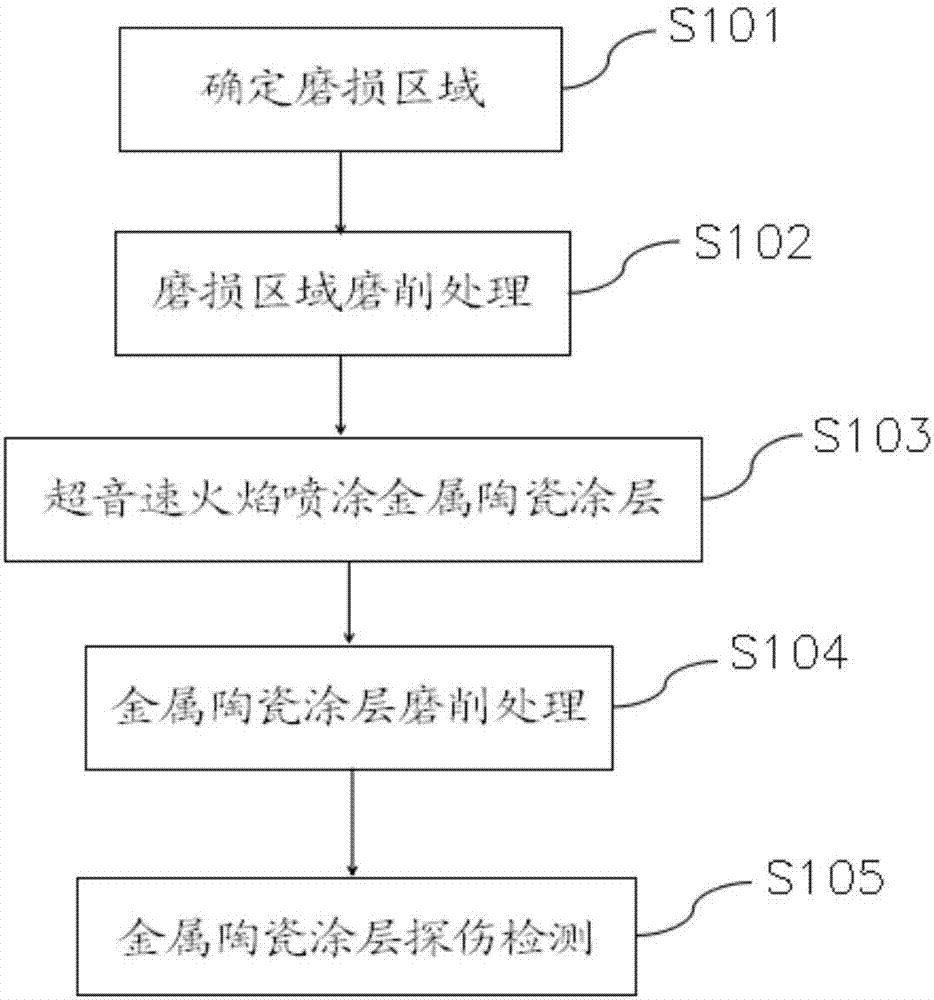

[0047] A centrifugal compressor shaft wear repair method: comprising the following steps:

[0048] Step S101, by performing a hardness test on the centrifugal compressor shaft made of 40CrNiMo7, determine whether there is a surface hardened layer on the centrifugal compressor shaft, if there is a surface hardened layer, the area covered by the surface hardened layer is a wear area, wherein, by The hardness tester is used to test the hardness of the shaft of the centrifugal compressor;

[0049] After the wear area is determined, check the coaxiality between the wear area and the shaft of the centrifugal compressor with a dial indicator to confirm whether the shaft of the centrifugal compressor is bent;

[0050] Wherein, the material of cermet coating comprises the following components in parts by weight:

[0051] Nickel: 50 parts, chromium: 30 parts, molybdenum: 30 parts, titanium carbide: 50 parts; wherein, the particle size of the material is 50 μm. The coating sprayed by t...

Embodiment 2

[0058] A centrifugal compressor shaft wear repair method: comprising the following steps:

[0059] Step S101, by performing a hardness test on the centrifugal compressor shaft made of 40CrNiMo7, determine whether there is a surface hardened layer on the centrifugal compressor shaft, if there is a surface hardened layer, the area covered by the surface hardened layer is a wear area, wherein, by The hardness tester is used to test the hardness of the shaft of the centrifugal compressor;

[0060] After the wear area is determined, check the coaxiality between the wear area and the shaft of the centrifugal compressor with a dial indicator to confirm whether the shaft of the centrifugal compressor is bent;

[0061] Wherein, the material of cermet coating comprises the following components in parts by weight:

[0062] Nickel: 30 parts, chromium: 20 parts, molybdenum: 40 parts, titanium carbide: 80 parts; wherein, the particle size of the material is 10 μm. The coating sprayed by t...

Embodiment 3

[0069] A centrifugal compressor shaft wear repair method: comprising the following steps:

[0070] Step S101, by performing a hardness test on the centrifugal compressor shaft made of 40CrNiMo7, determine whether there is a surface hardened layer on the centrifugal compressor shaft, if there is a surface hardened layer, the area covered by the surface hardened layer is a wear area, wherein, by The hardness tester is used to test the hardness of the shaft of the centrifugal compressor;

[0071] After the wear area is determined, check the coaxiality between the wear area and the shaft of the centrifugal compressor with a dial indicator to confirm whether the shaft of the centrifugal compressor is bent;

[0072] Wherein, the material of cermet coating comprises the following components in parts by weight:

[0073] Nickel: 80 parts, chromium: 10 parts, molybdenum: 20 parts, titanium carbide: 60 parts; wherein, the particle size of the material is 80 μm. The coating sprayed by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com