Thermal transfer powdery coating and preparation method and application thereof

A powder coating and thermal transfer printing technology, which is applied in the direction of powder coating, polyester coating, epoxy resin coating, etc., can solve the problem of inability to realize the mechanical properties and surface properties of the coating film, and the inability to withstand the high temperature curing and transfer of thermal transfer powder coatings. Printing conditions, limited range of substrate selection and other issues, to achieve the effect of good fullness and gloss, low curing temperature, and increase crosslinking density and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0080] Preparation of surface tension regulator polyethylene glycol grafted polybutylacrylate:

[0081] (1) Add 1mol PEG (M n 2000 g / mol), 1 mol of acrylic acid and 0.01 mol of p-toluenesulfonic acid, stirred and heated up to 110°C, and reacted at this temperature for 3 hours to obtain polyethylene glycol acrylate;

[0082] (2) Add 100mL xylene again in the polyethylene glycol acrylate that step (1) obtains, stir and be heated to reflux temperature, then dropwise add 1mol n-butyl acrylate and 0.3g benzoyl peroxide to the reactor The mixture was added dropwise for 3 hours; after the dropwise addition, the reaction was continued to be stirred at reflux temperature for 4 hours; cooled, and the solvent was removed by rotary evaporation to obtain the polyethylene glycol grafted polybutylacrylate.

[0083] The molecular weight of the polyethylene glycol-grafted polybutylacrylate was tested by GPC, and the number-average molecular weight was 9200 g / mol.

Embodiment 1~8

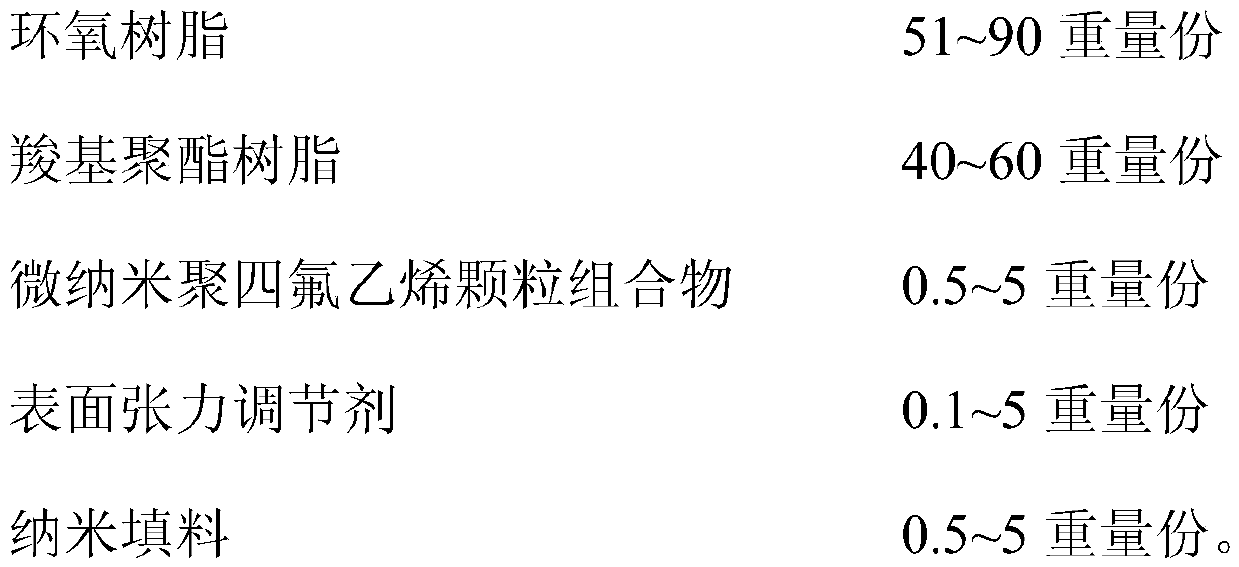

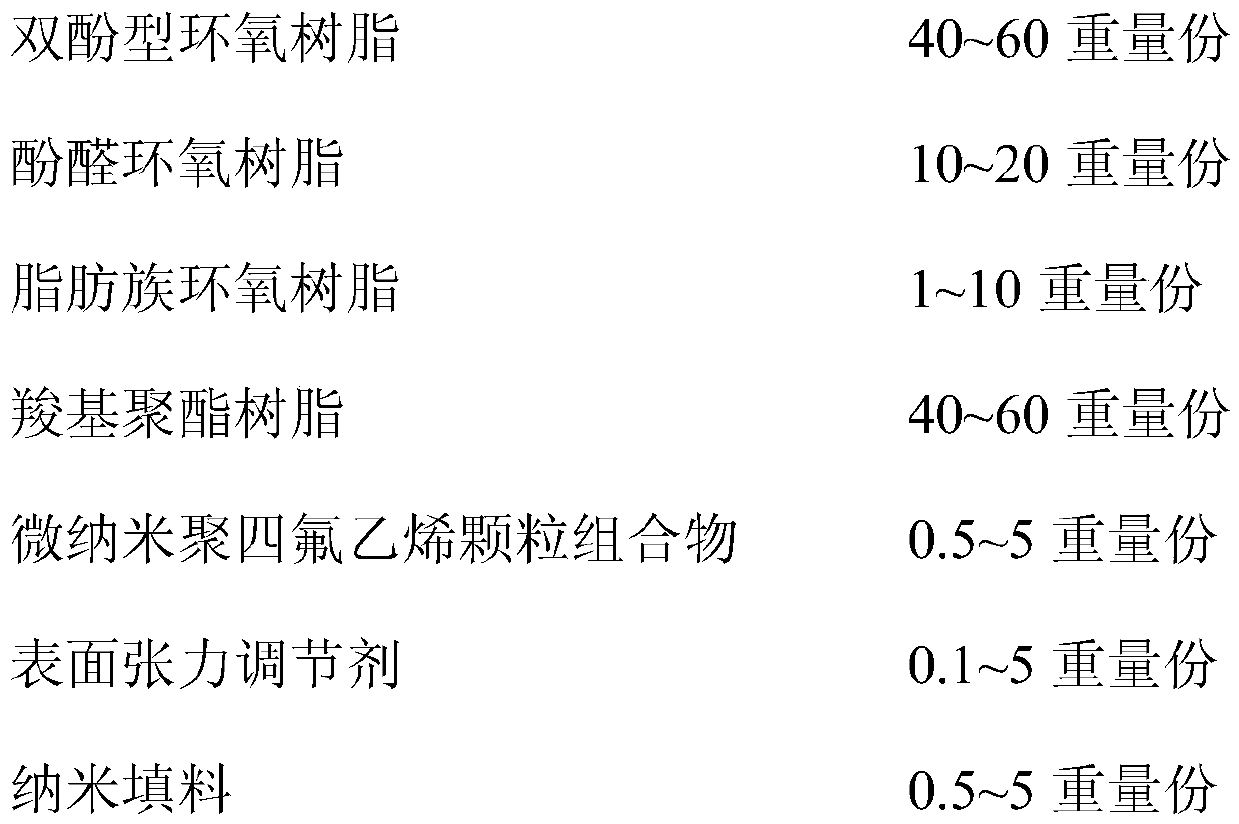

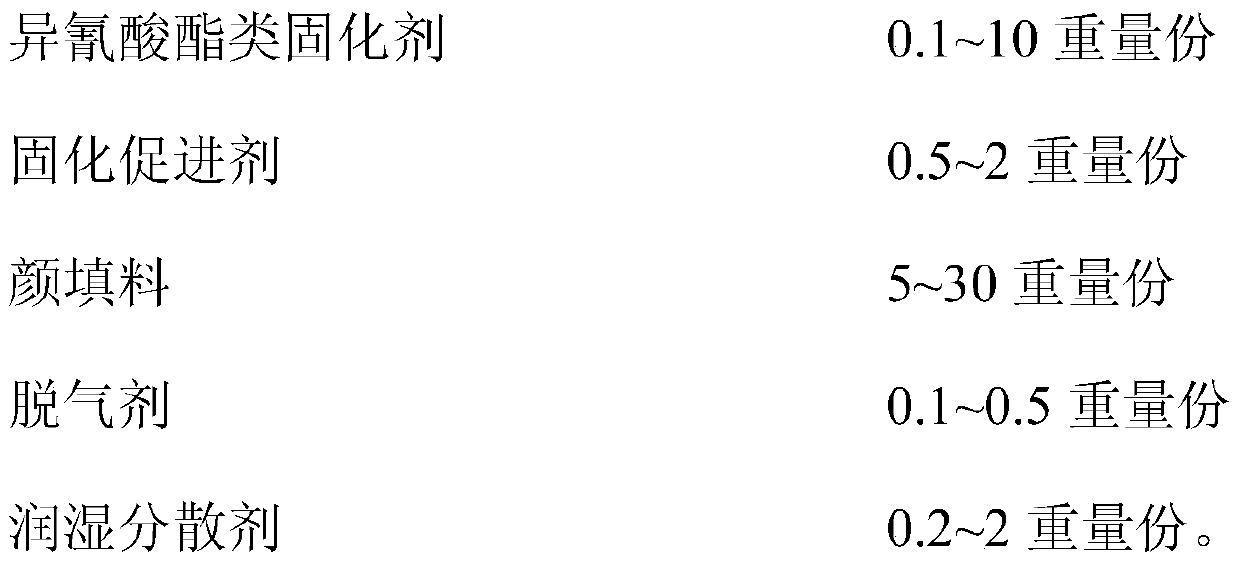

[0085] A thermal transfer powder coating, the specific components and dosage are shown in Table 1, and the units of the components are "parts by weight".

[0086] Table 1

[0087]

[0088]

[0089] Among them, the bisphenol A type epoxy resin is E12 (604) of Anhui Meijia, and the epoxy equivalent is 830; the epoxy equivalent of the novolak epoxy resin is 225 (Aralaite ECN 9669); the aliphatic epoxy resin is aliphatic glycidol Ether epoxy resin, the epoxy equivalent is 330 (Dow DER732); the acid value of carboxy polyester resin is 70 mg KOH / g (Crylcoat 1501); the average particle size of polytetrafluoroethylene particles A is 1 μm; polytetrafluoroethylene The average particle diameter of ethylene particle B is 200nm; Polyethylene glycol grafted polybutylacrylate is the polyethylene glycol grafted polyacrylate obtained in the preparation example; Oxane (Hybrid plastics, EP0409); isocyanate curing agent is internally blocked polyisocyanate (VESTAGON1321); wetting and dispe...

Embodiment 9

[0093] The difference between this embodiment and embodiment 4 is that the nano filler is alumina with an average particle diameter of 80 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com