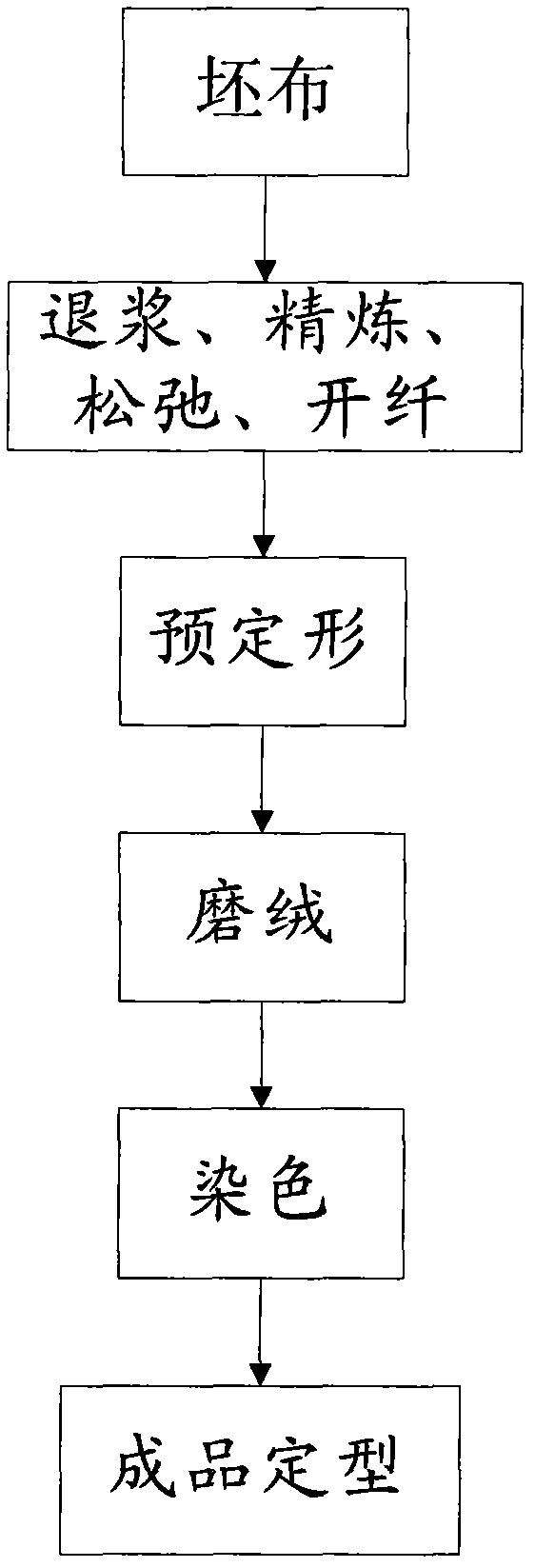

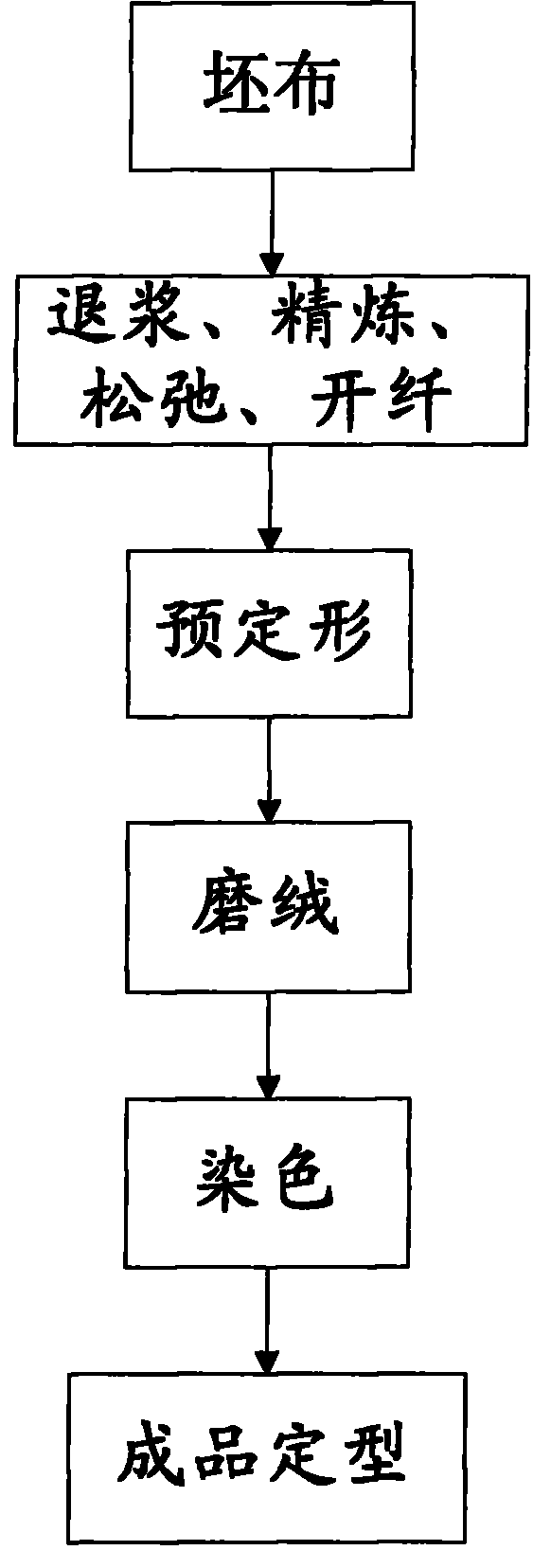

Dyeing and finishing process for suede fabric

A suede and fabric technology, applied in the field of dyeing and finishing technology, can solve the problems of fast dye adsorption, uneven dyeing, poor dyeing fastness, etc., achieve energy saving, environmental protection, high dyeing fastness, and good dyeing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1), gray cloth:

[0020] Sea-island type microfiber woven suede-like fabric, specifications: satin weave, warp 75D low elastic silk × weft 160D island silk;

[0021] Island-in-the-sea yarn: the conductive component is polyester, and the sea component is soluble polyester. .

[0022] (2), desizing, refining, relaxation, fiber opening:

[0023] Equipment: high temperature overflow jet dyeing machine;

[0024] Process conditions: 110°C, 30min;

[0025] Prescription: NaOH, 204B, DME-101; liquor ratio 1:15;

[0026] Quality requirements: weight reduction rate 13-15%, desizing rate 7-8%, shrinkage rate: 12-13%.

[0027] (3), sanding:

[0028] Equipment: CSM type sanding machine

[0029] Process conditions: cloth speed 30m / min, water pressure 3kg / cm2.

[0030] (4) Dyeing:

[0031] Equipment: supercritical CO2 fluid dyeing equipment

[0032] Process conditions: dyeing temperature is 110°C, dyeing pressure is 22MPa, dyeing time is 45min

[0033] Prescription: dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com