Method for preparing solvent-free polyurethane resin adhesive and use thereof

A polyurethane resin, solvent-free technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of limited hydrolysis resistance, poor colorability, poor color fastness, etc., to improve dyeability , The effect of better hydrolysis resistance and better hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

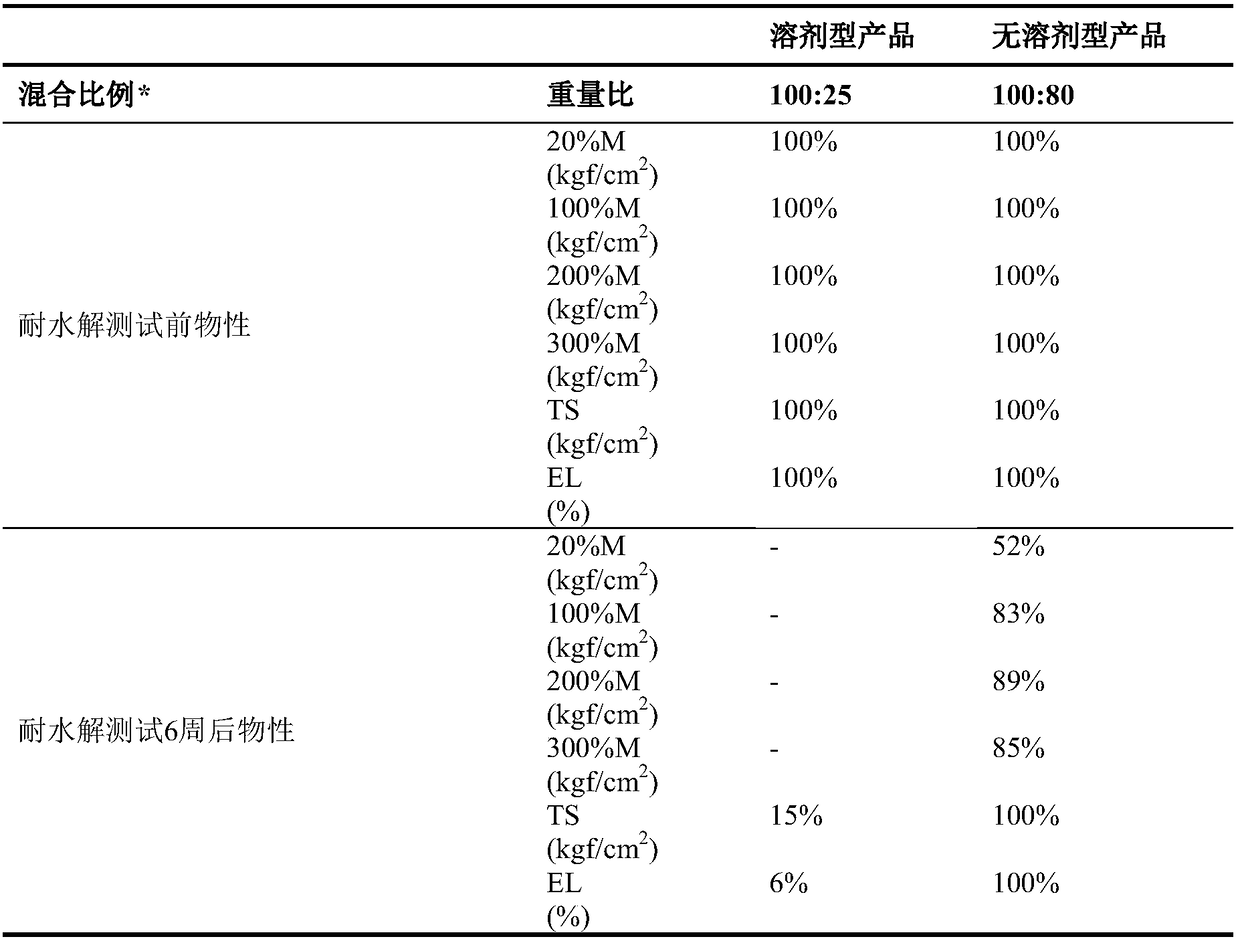

Examples

example 1A

[0098] Combine 50.3 g of polyoxypropylene glycol, 335.26 g of castor oil and its derivative polyol, 540 g of 2,4-diphenylmethane diisocyanate and 4,4-diphenylmethane diisocyanate mixture, and 1010 1.845g of antioxidant , Added to the reaction vessel, heated to 55-65°C with nitrogen and stirred and mixed. Track NCO changes by NCO titrator until the difference between NCO% before and after <0.05, that is, the end of the reaction is reached. When all the polyols and the isocyanate are completely reacted, the reaction product is a modified isocyanate.

example 1B

[0100] Add 240 g of polyethylene adipate diol, 96.3 g of polyoxypropylene glycol, 366 g of hexamethylene diisocyanate, and 1.76 g of antioxidant 1010 to the reaction vessel, and heat to 65-75°C with nitrogen. Stir and mix, track the NCO change with the NCO titrator, until the difference between NCO% before and after <0.05, that is, the end of the reaction is reached. When all the polyols and the isocyanate are completely reacted, the reaction product is a modified isocyanate.

example 2

[0102] Add 440.56 g of polyoxypropylene glycol, 572.72 g of polyhexanediol adipate glycol, 10105.06 g of antioxidants, and 0.15 to 0.25 g of stannous octoate as a catalyst into the reaction vessel, and heat to 45-55°C with nitrogen. Stir and mix. When all the polyols are uniformly mixed, the end of the reaction is reached.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com