Fabric dyeing depth difference processing method

A technology of dyeing depth and treatment method, which is applied in the field of poor dyeing depth treatment of textiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] Example 1, a method for processing the difference in depth of dyeing of textiles

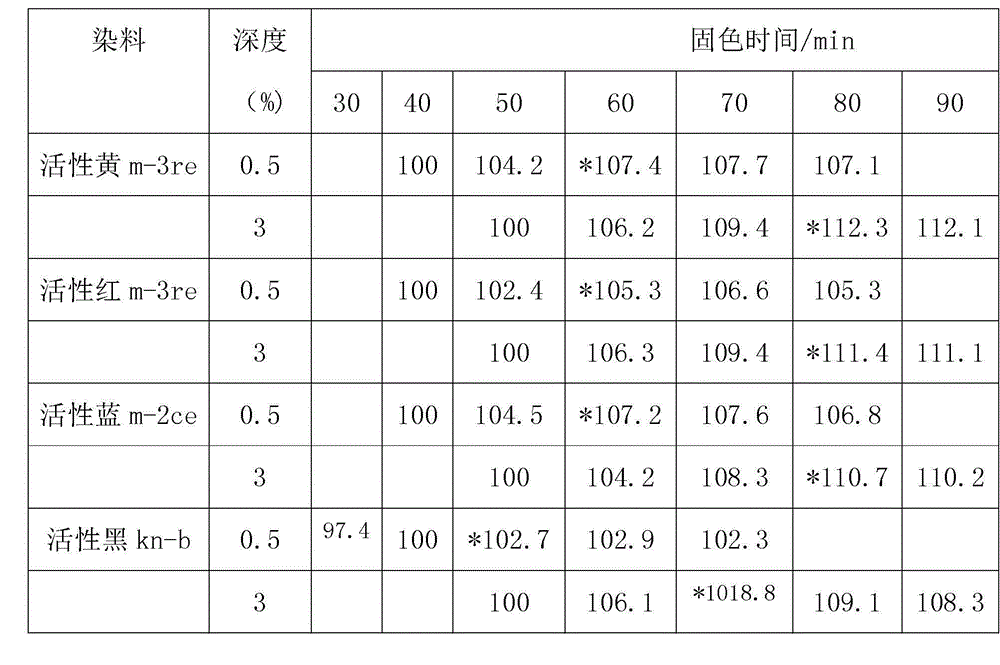

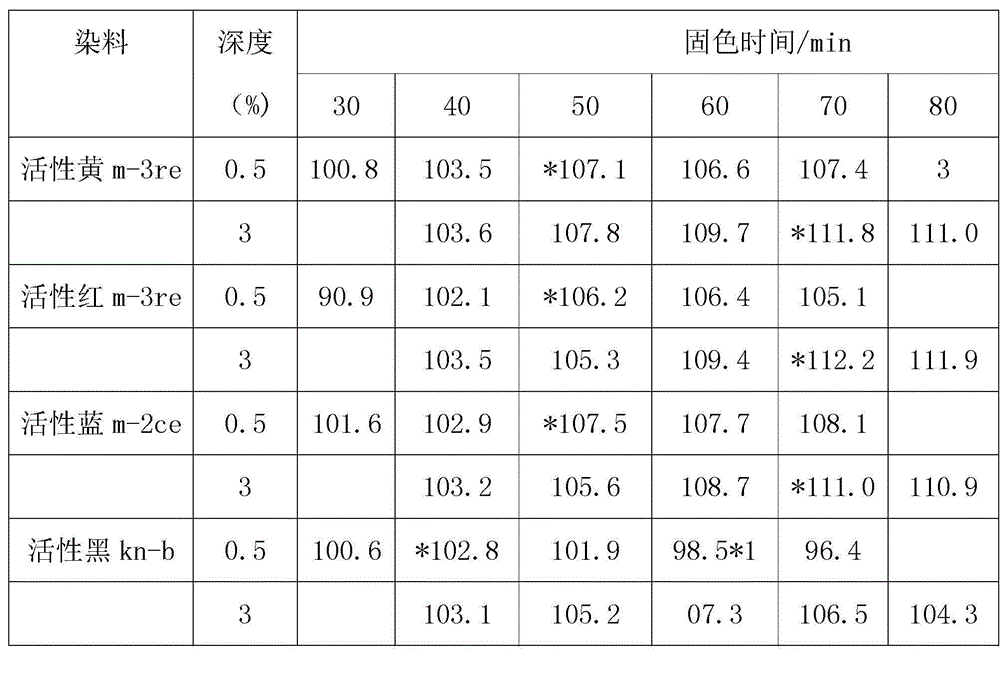

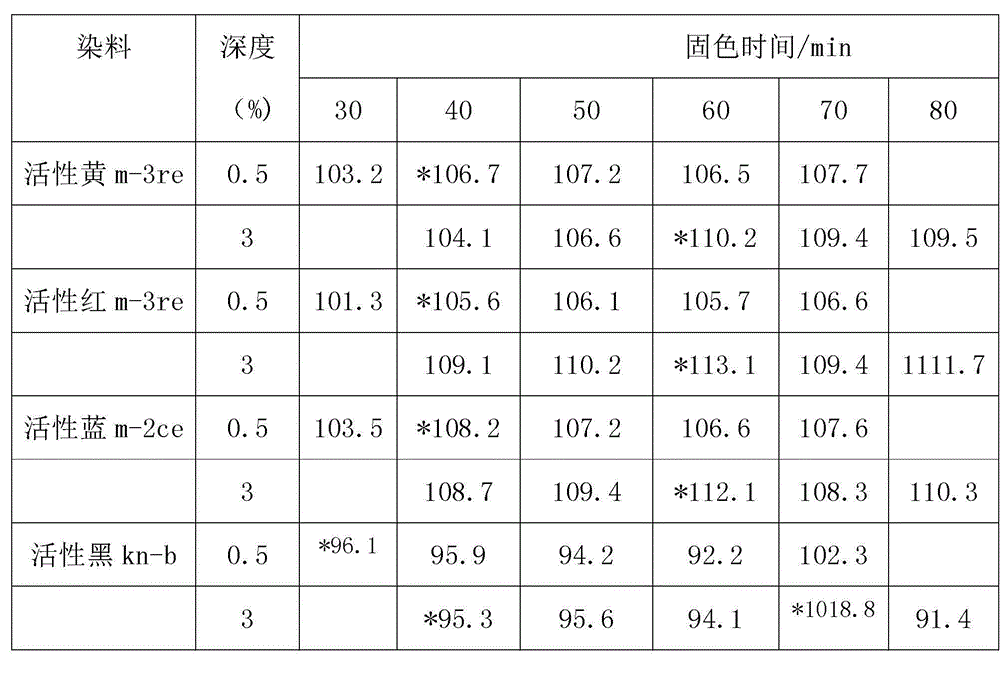

[0014] 1. Dyeing equilibrium time experiment of reactive dyes

[0015] 1.1 Experimental method

[0016] Dyeing formula: dyeing depth 0.5%, 3%, 0, W, f; sodium hexametaphosphate 1.5g / L; food 30g / L, 50g / L, soda ash 15g / L, 20g / L.

[0017] Dyeing conditions: bath ratio 1:30; dyeing temperature 60cC, 65cC, 70cc;

[0018] Dyeing time: absorb color for 30 minutes, fix color with alkali for 30-90 minutes; soaping, boiling temperature for 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com