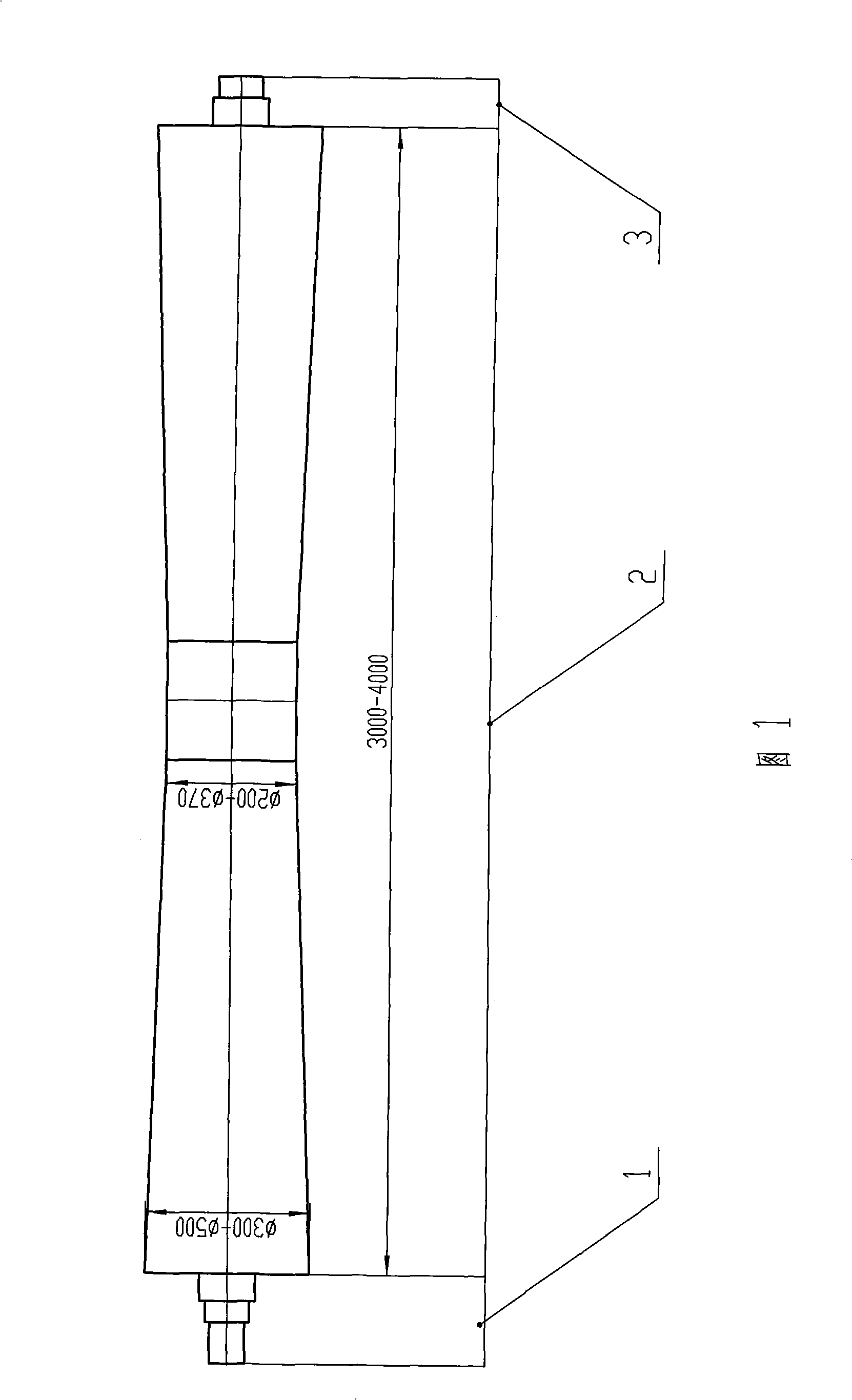

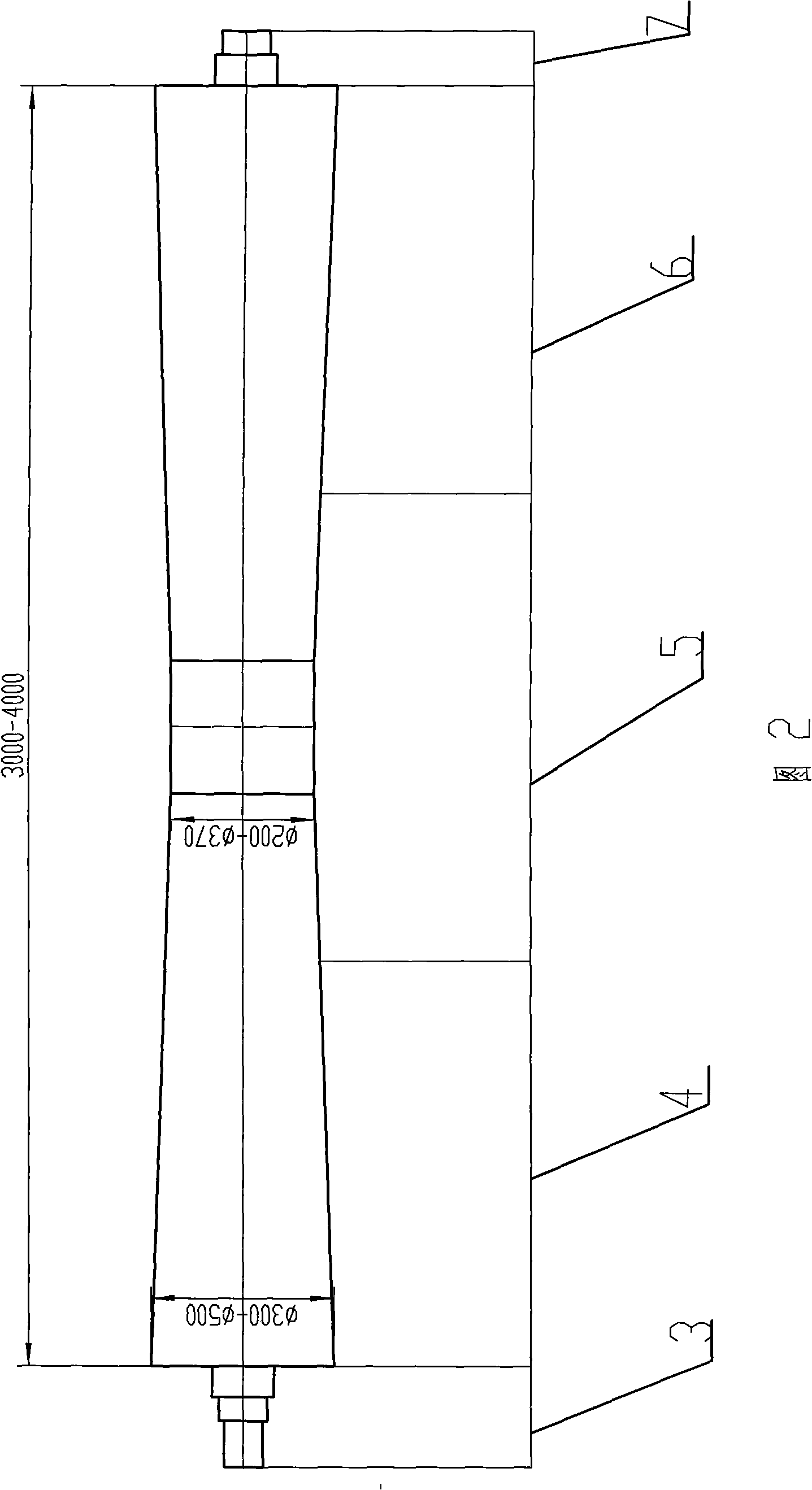

Technique and method for preparing biconical roller of large-sized strip hot-rolling mill transport roller

A production process and technology of a hot rolling mill, which is applied in the field of production process of double-cone rollers for transporting rollers of large-scale strip hot rolling mills, can solve problems such as inapplicability, and achieve the effect of uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Embodiments of the present invention are given to illustrate the present invention, but do not constitute any limitation to the present invention:

[0068] According to the structural characteristics and technical requirements of the double-cone rollers on the conveying roller table of the hot strip rolling mill, the processing technology of the double-conical rollers on the conveying roller table of the hot strip rolling mill is determined as follows:

[0069] 1) First, select a forging machine tool with a suitable tonnage to forge blanks, and the forging ratio must not be less than 3.5. In order to obtain a good forging with uniform distribution of chemical composition. Otherwise, the uneven distribution of chemical components will cause uneven quenching hardness on the surface of the roll body. The material of the double tapered roller of the conveying roller table is 45 or 42CrMo.

[0070] 2) The first heat treatment of the forging adopts normalizing treatment. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com