Inkjet printing method ensuring dye penetration effect of heavy fabric

A technology of inkjet printing and heavy fabrics, applied in the direction of copying/marking method, printing, printing post-processing, etc., can solve the problems of insufficient inkjet printing dye penetration rate, etc., to improve equipment utilization rate, increase authenticity rate, and quality easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take a roll of napped polyester polar fleece fabric (belonging to napped thick fabric, with a thickness of 3 mm), sizing, and rolling up for later use.

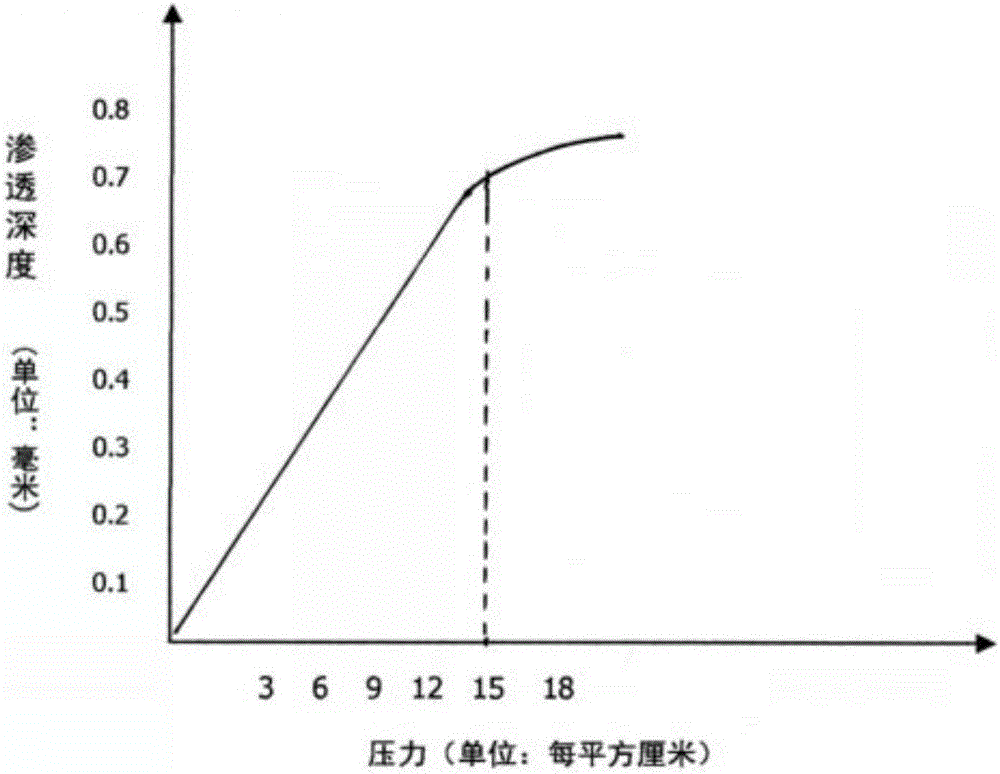

[0039] Choose Foshan Hope Gaoke HF01 high-speed inkjet printing machine, load high-temperature disperse ink; then install the above-mentioned polyester polar fleece fabric with good starch on the inkjet printing machine, and select the ink volume as 10g / m 2 Color block, inkjet printing; at the same time, the polar fleece fabric that has been inkjet printed is passed through a roller press at a temperature of 20°C and a pressure of 0-20KG / CM 2 Rolling and pressing at different pressures within the range, drying, and then steaming with superheated steam at 180°C for 7 minutes to fix the color of the disperse dyes, and finally washing and drying; then take samples of different pressures to measure the penetration depth of the dyes. The data are shown in the table 2. It can be seen that when the pressure is 15.3kg / cm 2 Wh...

Embodiment 2

[0044] Take a roll of flocking cloth with a nylon hair height of 3 mm, sizing, drying, and rolling up for later use.

[0045] Choose the V3000 inkjet printing machine of Honghua Digital Co., Ltd., and pour the acid ink produced by Honghua Co., Ltd.; then install the above-mentioned flocking cloth with good size on the inkjet printing machine, and select the ink volume as 10g / m 2 Color block, inkjet printing; at the same time, the flocking cloth that has been inkjet printed is passed through a roller press at a temperature of 20°C and a pressure of 0-20KG / CM 2 Take different pressures within the range, dry them, and then steam them with saturated steam at 105°C for 50 minutes to fix the color of the acid dyes, and finally wash and dry them with water; then take samples of different pressures to measure the penetration depth of the dyes. The data are shown in the table 2. It can be seen that when the pressure is 14.8kg / cm2 When the penetration depth is 0.8 mm, it fully meets the...

Embodiment 3

[0050] Take some cashmere brushed fabrics with a weight of 600 grams per square meter in Erdos, sizing, drying, and rolling them up for later use.

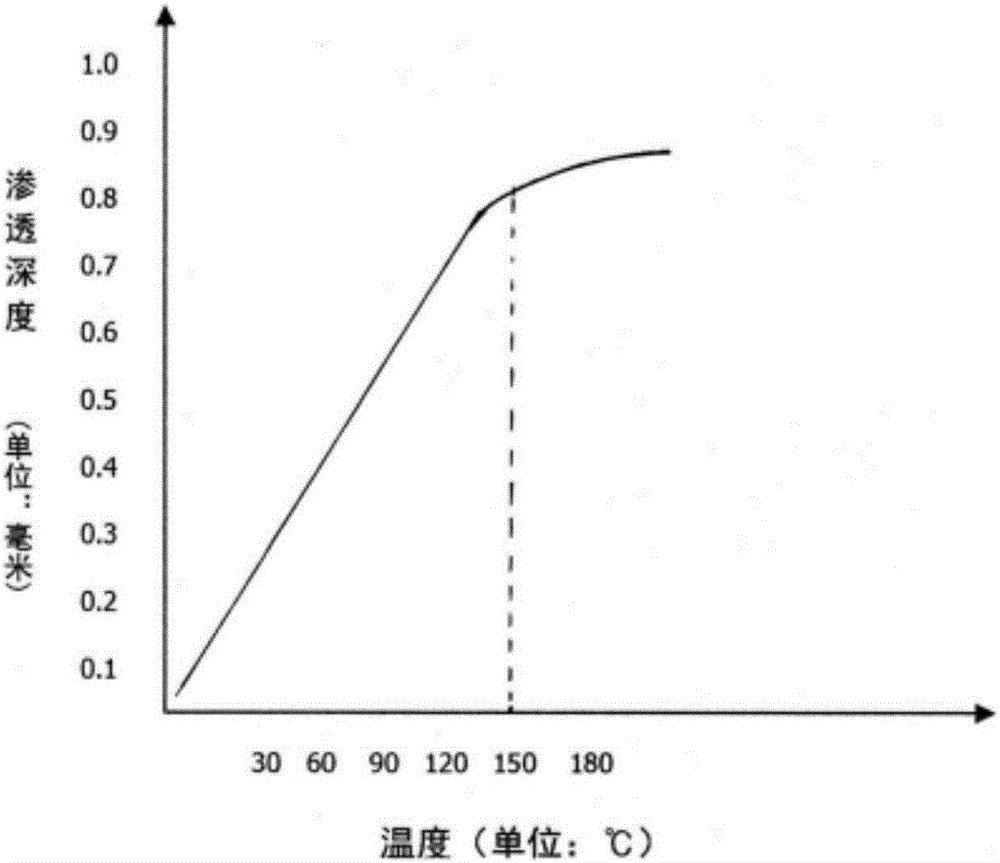

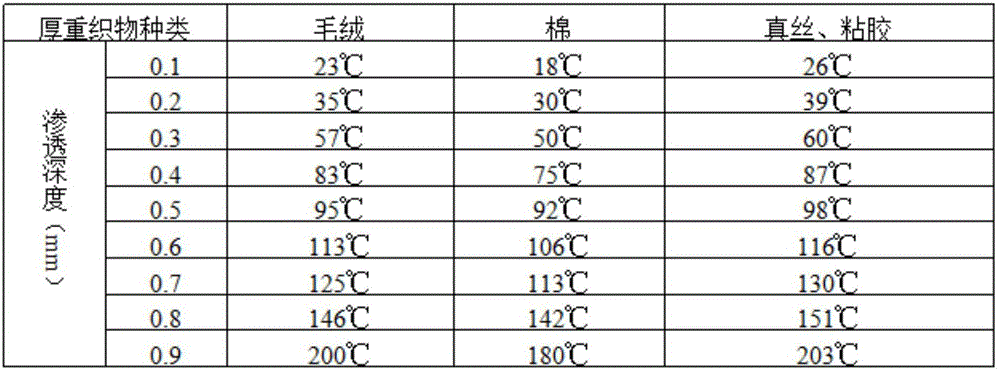

[0051] Choose the inkjet printing machine of ZIMMER Company in Austria, load the active ink of Huntsman Company, and then install the above-mentioned cashmere napped fabric with good size on the inkjet printing machine, and select the ink volume as 10g / m 2 Color block, carry out ink-jet printing; At the same time, the flocking cloth that has been ink-jet printed is passed through a roller press, and the pressure is 15kg / cm 2 , rolling and pressing at different temperatures within the temperature range of 15-210°C, drying, and then steaming with saturated steam at 105°C for 60 minutes to fix the color of the reactive dye, and finally washing and drying; then take samples at different temperatures and measure Dye penetration depth, the data is shown in Table 1, it can be seen that when the pressure is 146 ° C, the penetration depth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com