Liquid granite coating

A granite coating, liquid technology, applied in the direction of coating, etc., can solve the problems of poor stability, cross-color, poor weather resistance, etc., and achieve good adhesion and good granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions in the embodiments of the present invention will be clearly and completely described below.

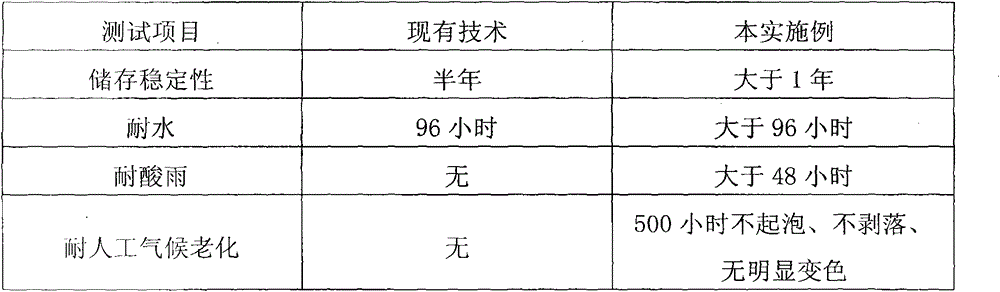

[0012] The present invention provides a kind of liquid granite coating, good stability, good weather resistance, specific examples are as follows:

[0013] Non-ionic protective colloid solution 40%, silicone acrylic emulsion 30%, base paint 20%, thickener 2%, water 8%.

[0014] Among them, the basic paint includes calcium carbonate 10%, kaolin 10%, titanium dioxide 10%, styrene-acrylic emulsion 30%, dispersant 2%, defoamer 1%, film-forming aid 2%, water 20%, color paste 15% %.

[0015] The preparation process is as follows: first prepare the base paint, 10% calcium carbonate, 10% kaolin, 10% titanium dioxide, 30% styrene-acrylic emulsion, 2% dispersant, 1% defoamer, 2% film-forming aid, 20% water % into the mixer for stirring, then add 15% of color paste for coloring, the prepared base paint is added to 40% of non-ionic protective colloid solution, 30%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com