Ceramic secondary reinforcement method

A technology of ceramic core and secondary strengthening, which is applied in the direction of core, mold, and mold composition, which can solve problems such as broken cores and cannot fully meet production requirements, so as to improve the pass rate of castings and reduce broken cores Defects, the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Take the second-stage guide vane of a machine as an example. The implementation process is as follows: ceramic core secondary strengthening method, this method includes the following steps:

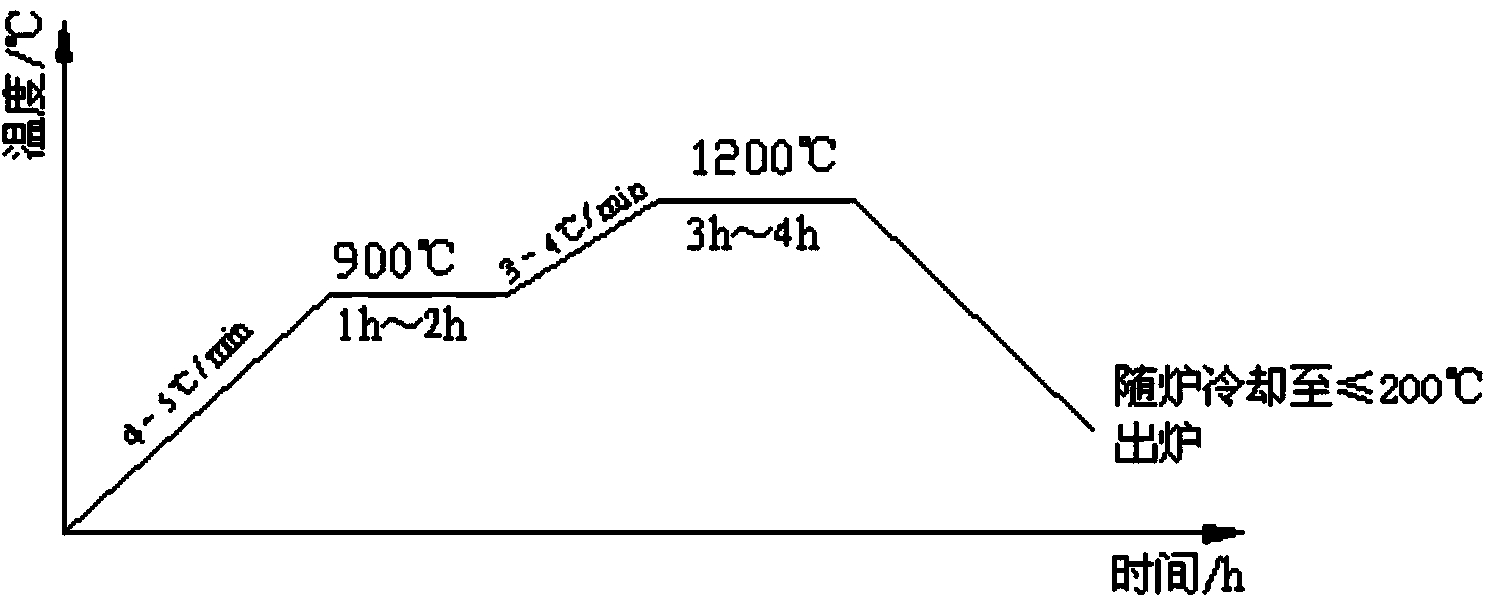

[0015] In the first step, the dewaxed mold shell with the ceramic core is subjected to secondary baking. The baking process is as follows: the temperature is raised from room temperature to 900 °C at a rate of 4 °C per minute, kept for 1 hour, and then heated at a temperature of 3 °C per minute. The heating rate is raised from 900°C to 1200°C, kept for 3 hours, and finally cooled to below 200°C with the furnace.

[0016] The second step is to perform secondary strengthening on the mold shell with ceramic core after the second firing. The strengthening process is as follows: Slowly pour the ethyl silicate hydrolyzate from the sprue cup of the mold shell into the baked mold shell After soaking for 20 minutes, pour out the ethyl silicate hydrolyzate until it is submerged to the sprue...

Embodiment 2

[0018] Take the first-stage guide vane of a machine as an example. The implementation process is as follows:

[0019] A secondary strengthening method for a ceramic core, the method comprising the following steps:

[0020] In the first step, the dewaxed mold shell with the ceramic core is subjected to secondary baking. The baking process is as follows: the temperature is raised from room temperature to 900 ° C at a heating rate of 4.5 ° C per minute, kept for 1.5 hours, and then heated at 3.5 ° C per minute. The heating rate is raised from 900°C to 1200°C, kept for 3.5 hours, and finally cooled to below 200°C with the furnace.

[0021] The second step is to perform secondary strengthening on the mold shell with ceramic core after the second firing. The strengthening process is as follows: Slowly pour the ethyl silicate hydrolyzate from the sprue cup of the mold shell into the baked mold shell After soaking for 30 minutes, pour out the ethyl silicate hydrolyzate until it is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com