Curing agent for Furane self-hardening resin, preparation method thereof and Furane self-hardening resin sand

A furan no-bake and curing agent technology, which is applied in the field of furan no-bake resin sand and furan no-bake resin curing agent, can solve the problems of expensive raw materials and high production cost of curing agent, achieve good collapsibility, moderate curing speed, and source wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

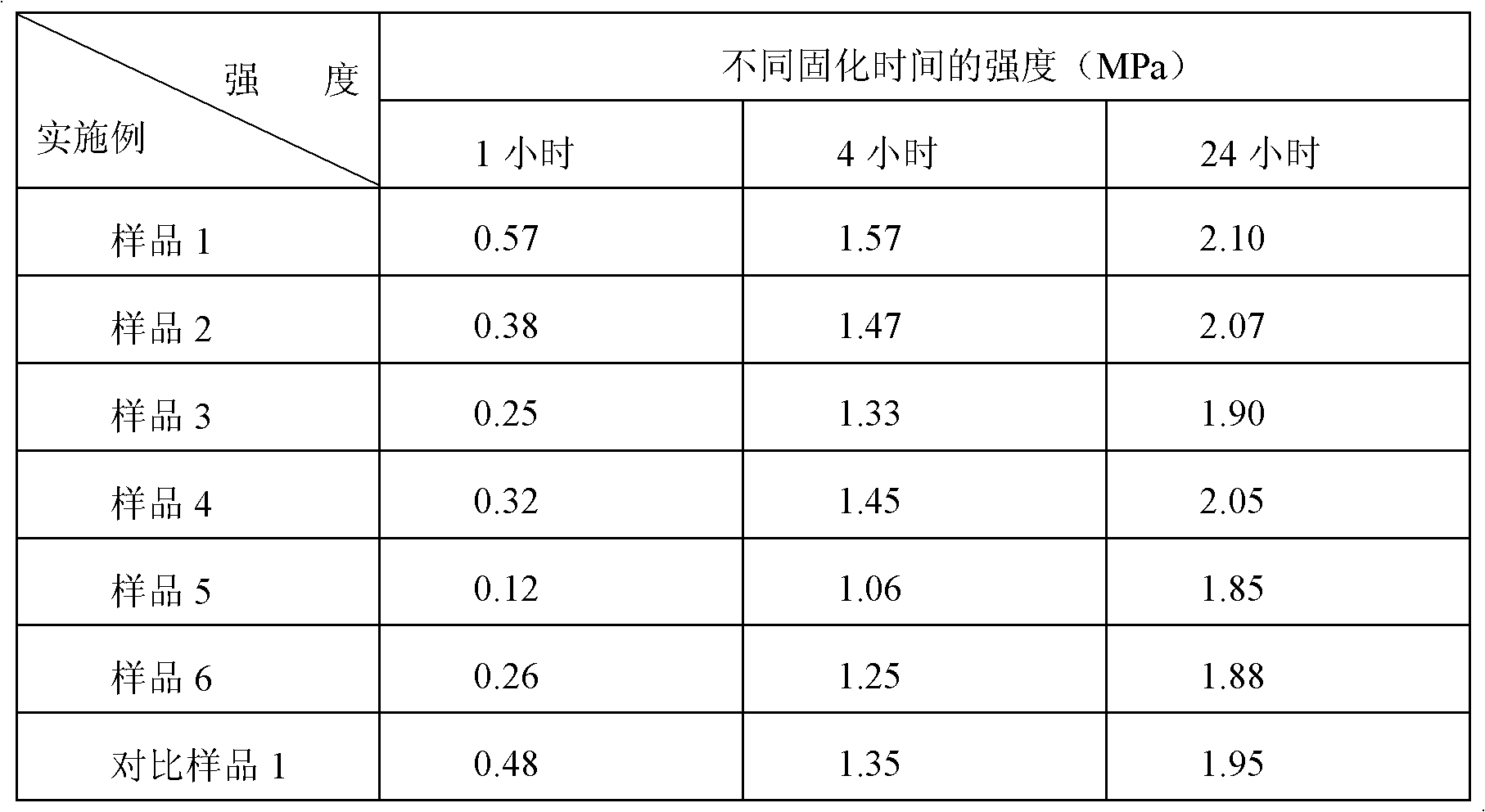

Examples

preparation example Construction

[0026] In a typical implementation of the present invention, a kind of preparation method of curing agent for furan no-bake resin, comprises the following steps: take the industrial product produced in the process of producing benzenesulfonic acid, p-toluenesulfonic acid or xylenesulfonic acid One, two or mixtures of waste acids are made into mother liquor, and the curing agent is prepared by using the mother liquor.

[0027] The curing agent for furan no-bake resin provided by the present invention is mainly composed of one, two or three mixtures of industrial waste acids produced in the process of producing benzenesulfonic acid, p-toluenesulfonic acid or xylenesulfonic acid, Even use only this spent acid as curing agent. When only this waste acid is used as the curing agent, the curing agent can be obtained by simply collecting the industrial waste acid produced in the process of producing benzenesulfonic acid, p-toluenesulfonic acid or xylenesulfonic acid and mixing them. ...

Embodiment 1

[0041] Raw materials: 57% sulfonic acid concentration, 10% sulfuric acid concentration mother liquor: 100g; 98% sulfuric acid concentration: 50g; xylene: 10g; methanol: 10g; water: 5g.

[0042] Add the mother liquor to a three-necked flask equipped with a thermometer, a stirring paddle and a vacuum dehydration device, dehydrate at 100°C for 1 hour under vacuum conditions, cool to 80°C, add 98% sulfuric acid, xylene, and react at 110°C After 4 hours, cool to 60°C and add methanol. At this time, the temperature is 50°C. React for 1.0 hour, then cool to 40°C, add water, mix well, and discharge to obtain curing agent sample 1.

Embodiment 2

[0044] Raw materials: mother liquor with 45% sulfonic acid concentration and 30% sulfuric acid concentration: 50g; oleum: 45g; toluene: 20g; xylene: 20g; water: 40g.

[0045] Add the mother liquor into a three-neck bottle equipped with a thermometer, a stirring paddle and a vacuum dehydration device, dehydrate at 150°C for 1.5 hours under vacuum conditions, cool to 50°C, and replace the vacuum dehydration device with a normal pressure water separator. Add fuming sulfuric acid, toluene, and xylene, and react at 105°C for 4 hours. Water is continuously separated during the reaction. When no more water is separated from the water separator, the reaction is terminated, and benzene is removed under reduced pressure. Cool to 50°C, add water, mix evenly, and discharge to obtain curing agent sample 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com