Internal spline shaft and preparation method thereof

A technology of inner spline and inner cavity, which is applied in the transmission shaft and its processing field, can solve the problems of low machining accuracy and short service life of the inner spline shaft, and achieve high production efficiency, long service life and guaranteed spline accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

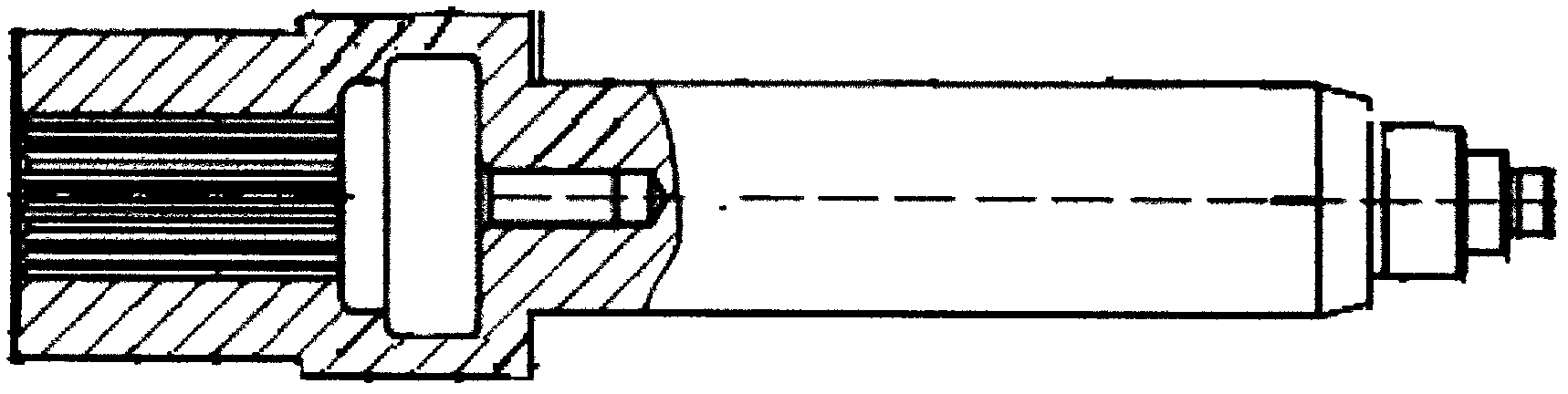

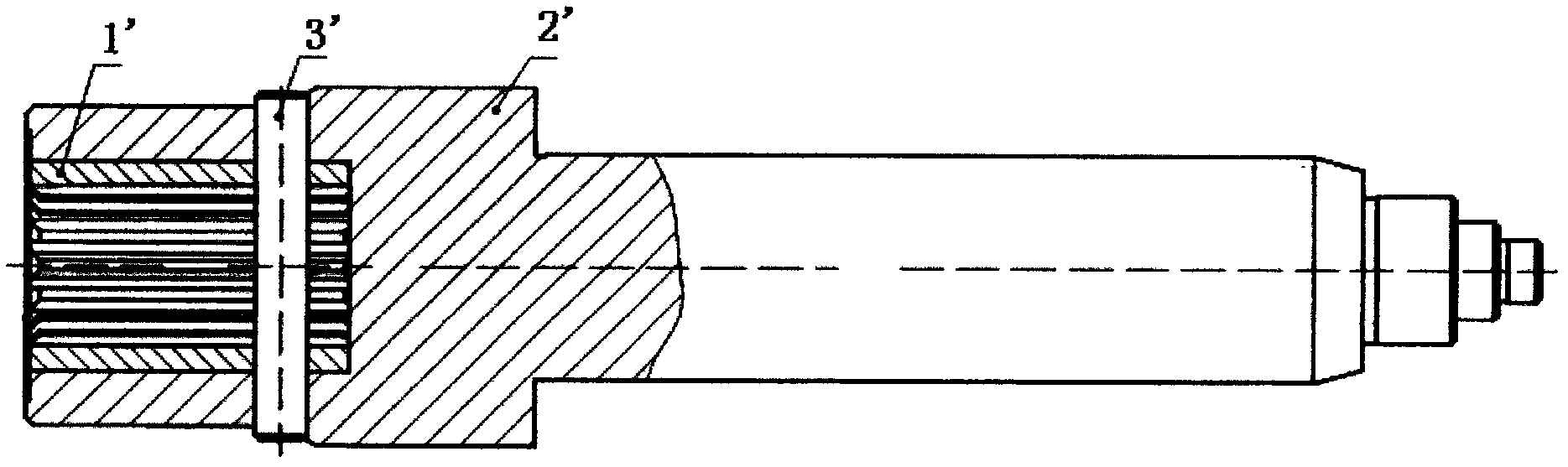

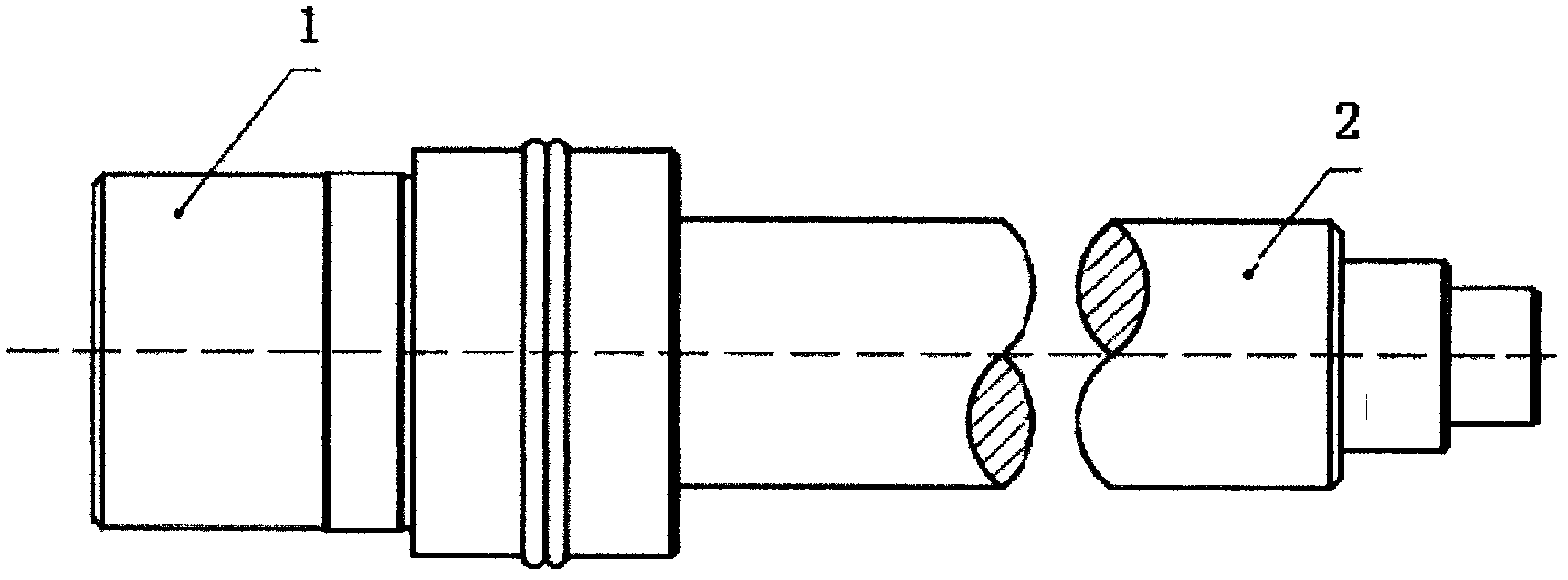

[0042] The inner spline shaft of the present invention is as image 3 As shown, it includes a head 1 and a tail 2, and the head 1 and the tail 2 are connected as one by friction welding. Such as Figure 4 As shown, the head 1 includes a columnar part 11 and a guide post part 12, the outer diameter of the guide post part 12 is larger than that of the columnar part 11, the inner cavity 111 of the columnar part 11 has spline teeth 13, and the guide post part 12 also has an inner cavity 121 . Such as Figure 5 As shown, the tail part 2 includes a connection part 21, a rod part 22 and a pin part 23 connected in sequence, the diameter of the connection part 21 is larger than the rod part 22, the diameter of the rod part 22 is larger than the pin part 23, and the connection part 21 has a The inner cavity 211 has a central hole at the end of the pin portion 23 . From Figure 5 It can be seen that the pin portion 23 may also comprise two parts with reduced diameter.

[0043] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com