Injection pump for internal-combustion engine and internal-combustion engine

A technology for injection pumps and internal combustion engines, applied in fuel injection pumps, fuel injection devices, machines/engines, etc., can solve problems such as suction hole cavitation, achieve long service life, reduce wear, and increase maintenance intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

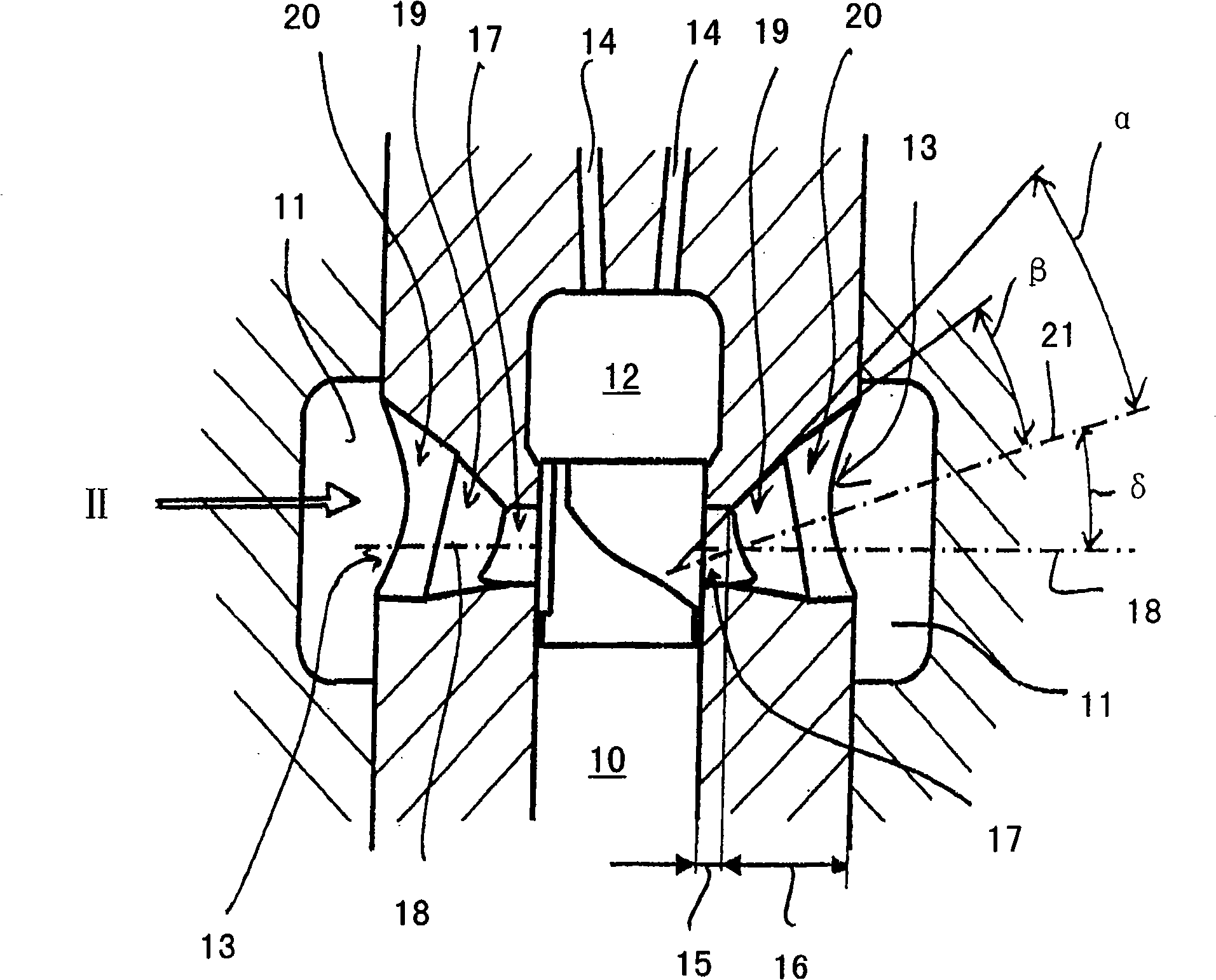

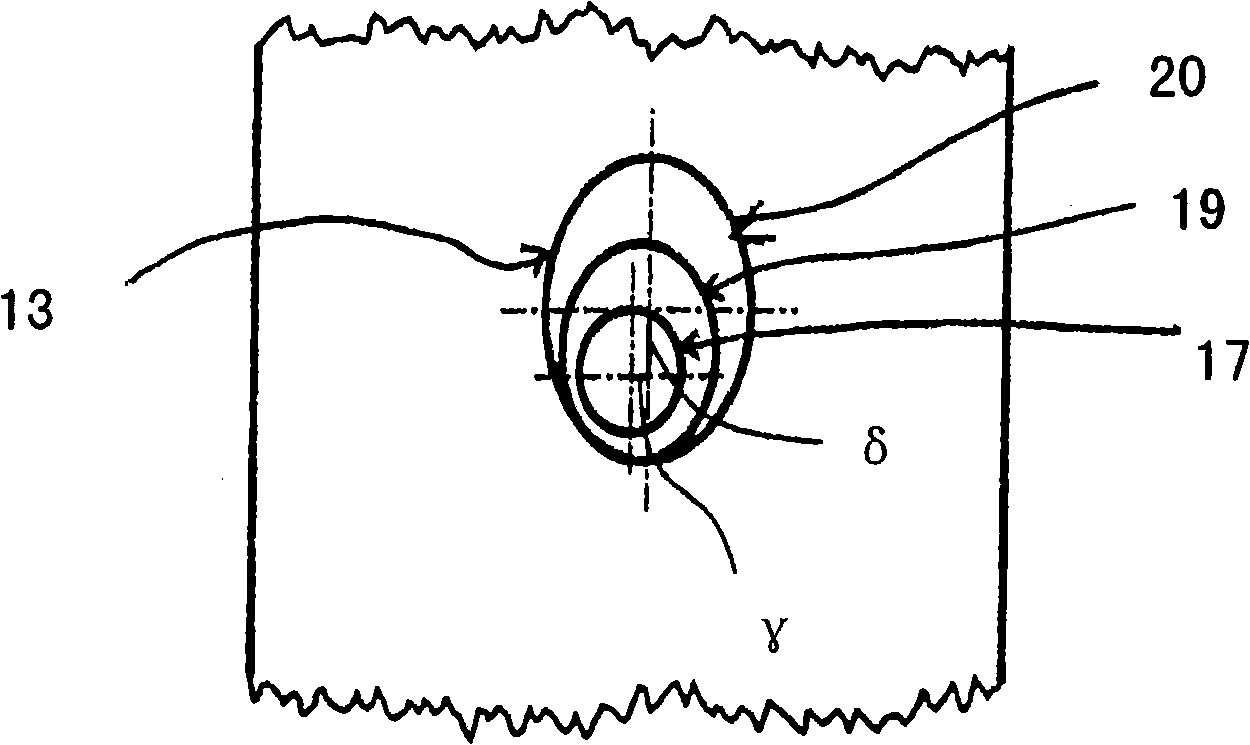

[0011] figure 1 A so-called inclined-edge controlled piston high-pressure injection pump for a diesel internal combustion engine is shown in a schematic partial cross-section, wherein the injection pump comprises a piston 10 which cooperates with a suction chamber 11 and a high-pressure chamber 12 of the injection pump . The suction chamber 11 is usually connected to the high-pressure chamber 12 via two suction holes 13 . It is pointed out that only one suction hole or more than two suction holes may also be present. Depending on the position of the piston 10 , the piston either releases the suction opening 13 or 10 and closes the suction opening 13 . With the piston 10 closing the suction opening 13 (during most of the upward movement of the piston 10 ) the flow of fuel from the suction chamber 11 of the injection pump into the high pressure chamber 12 is inhibited.

[0012] On the other hand, when the piston 10 releases the suction opening 13 and there is a lower pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com