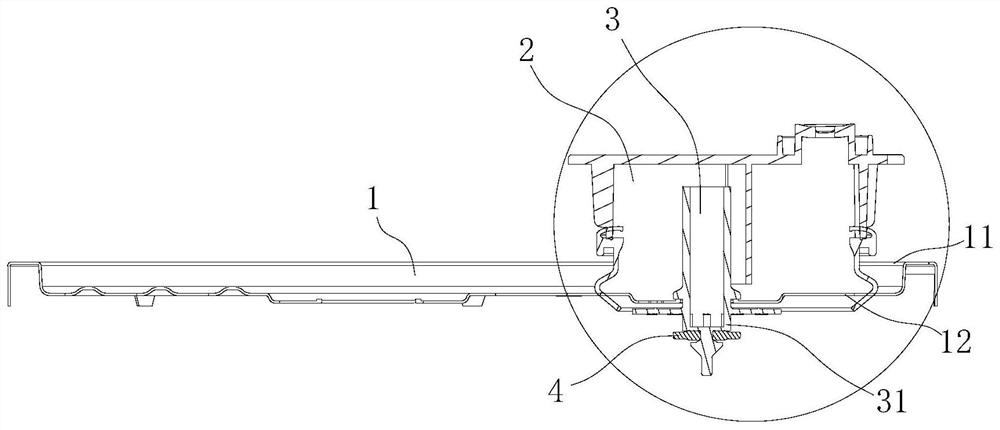

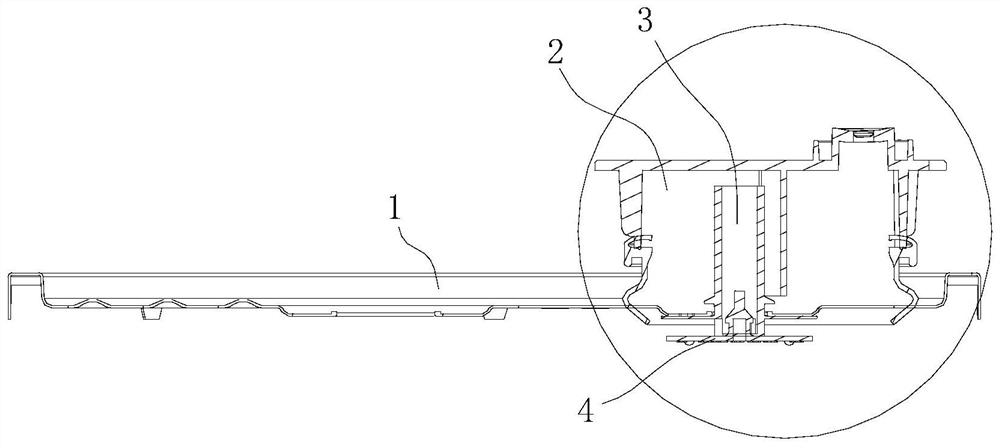

Anti-overflow pot cover assembly for cooking device and cooking device

A cooking device and anti-overflow technology, applied in the field of kitchen utensils, can solve the problems of inconvenient disassembly by users, large and complicated steam valve body, etc., and achieve the effect of simple steam flow path, improved user experience, and small overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

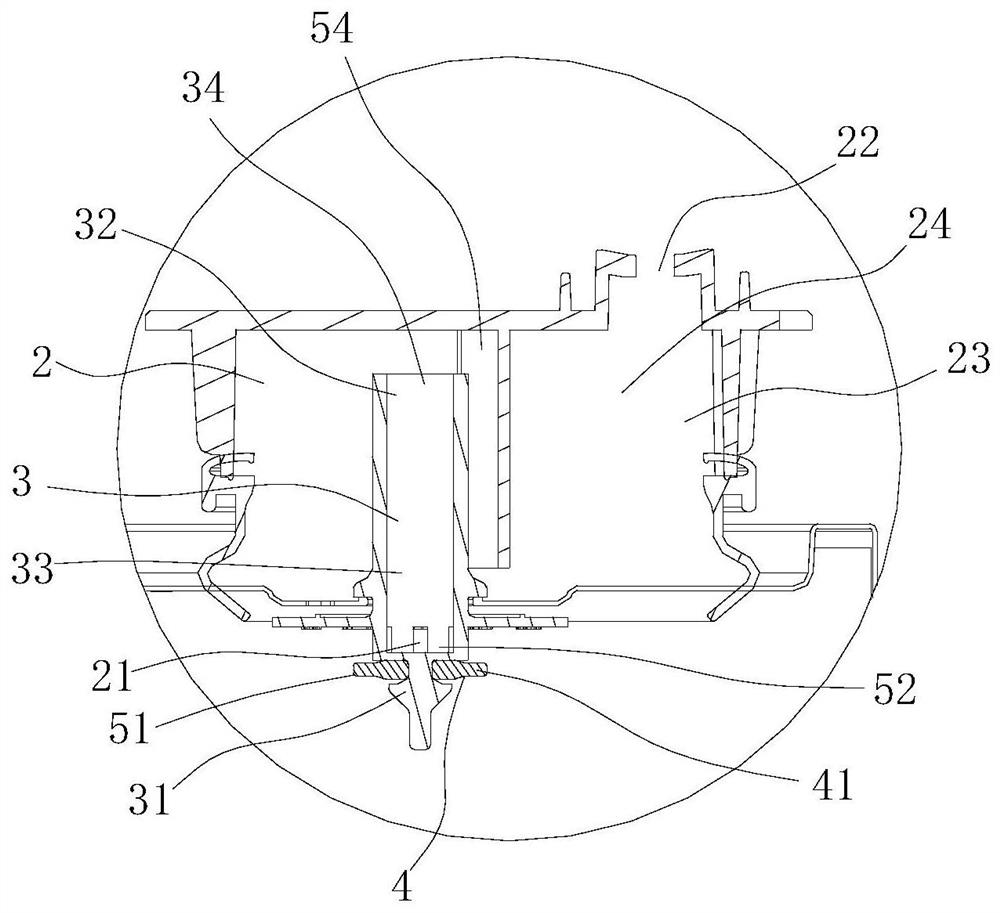

[0061] Embodiment 1: In this embodiment, the first anti-overflow and bubble-breaking part 41 is fixedly connected to the steam inlet end 31 to improve the connection between the first anti-overflow and bubble-breaking part 41 and the flow guide part 3 . The connection strength improves the integrity of the structure. In this embodiment, there is no specific limitation on the way of the fixed connection, which can be integrally formed, glued, etc., if the material of the first anti-overflow and bubble breaking part 41 is different from that of the flow guide 3, It can also be fixedly connected by means of double injection molding and the like.

Embodiment approach 2

[0062] Embodiment 2: In this embodiment, the first overflow-proof and foam-breaking part 41 is detachably connected to the steam inlet end 31, so that users can remove the first overflow-proof and foam-breaking part 41 for convenience. Clean up.

[0063] In this embodiment, there is no specific limitation on the detachable connection method, which includes but is not limited to the situations listed in the following examples:

Embodiment 1

[0064] Embodiment 1: As an example of this embodiment, the first overflow-proof and bubble-breaking part 41 is screwed to the flow guide 3, and the threaded connection makes the first overflow-proof and bubble-breaking part The connection of 41 is more reliable and stable, and the structure is simple and easy to disassemble.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com