Core manufacturing method

A manufacturing method and core technology, applied in the field of core manufacturing, can solve problems such as low feasibility, difficulty in obtaining cores, and unsatisfactory effects, and achieve the effects of strictly preventing oil and water spillage, preventing pollution, and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

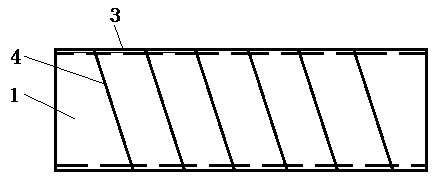

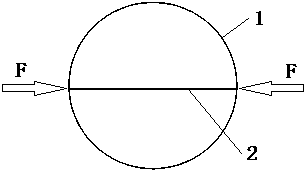

[0027] The specific implementation of the core manufacturing method in the present invention will now be described in conjunction with the accompanying drawings.

[0028] Embodiment of the core manufacturing method in the present invention: the core manufacturing method is mainly to artificially create fractures on the core, and use the cracks in the core to conduct experiments to provide data support for subsequent oil recovery work. Operators can select the core collection location in the research area, and obtain cores that are closer to the real reservoir through on-site coring, or directly obtain cores corresponding to the target oil reservoir in the core library. The operator can take out a long section of core, drill several small columnar cores with a length of 5-8cm on this section of core, and trim the end faces of these cores, so that these small cores have a uniform columnar shape and a flat end face .

[0029] After trimming, these shorter rock cores are subjecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com