High-efficiency and low-consumption device for improving hydrolytic acidification effect of excess sludge and operation method thereof

A technology for hydrolysis and acidification of sludge and hydrolysis and acidification, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of low volatile fatty acid production, high energy and chemical consumption, and high equipment requirements. To achieve the effect of enhancing and enriching, improving contact efficiency, and improving microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

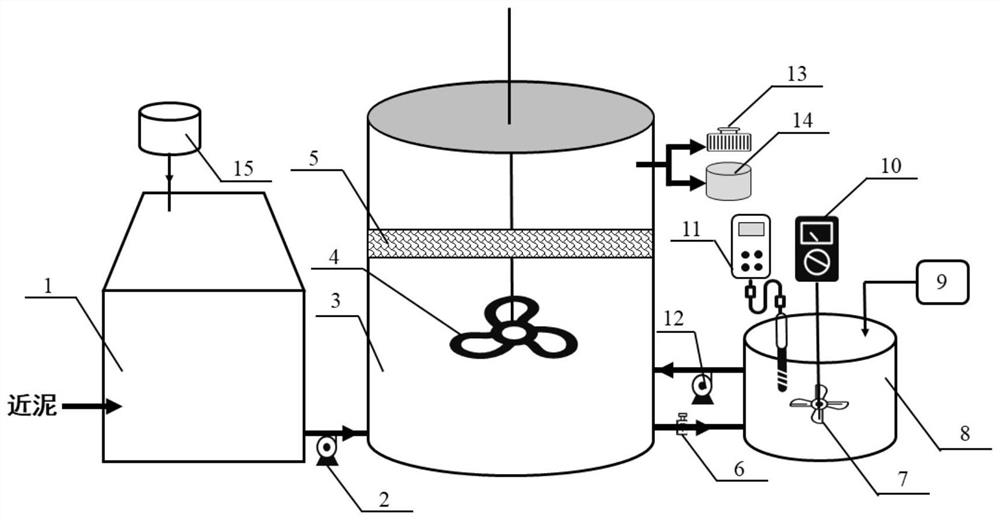

[0025] In this example, a set of small-scale experimental equipment is used. The excess sludge to be treated is taken from the secondary sedimentation tank of a certain urban sewage treatment plant. The sludge concentration is 19.7±0.7g / L, the total COD of the sludge is 17.1±1.1g / L, and the pH is 6. 8-7.2, soluble COD169-264mg / L. The remaining sludge directly enters the sludge hydrolysis acidification tank 3 through the adjustment tank 1, the included angle between the baffle plate 5 and the vertical surface of the sludge hydrolysis acidification tank 3 is 15°, and the ratio of the height of the baffle plate 5 to the height of the tank body is 15% , the unit weight of the soft biological carrier fixed on the board is 2.0kg / m 3, the fiber bundle length is 60mm, the bundle diameter is 0.3mm, the distance between bundles is 10mm, and the porosity is >99%. Bottom 2cm; The ratio of the diameter of the fast stirrer 7 of the outer circulation weak alkali fast stirring tank 8 to the ...

Embodiment 2

[0027] The difference from Example 1 is that the treated excess sludge is taken from the secondary settling tank of another urban sewage treatment plant, the sludge concentration is 23.21±0.62g / L, the volatile suspended solid concentration is 14.34±0.41g / L, and the SCOD is 317.9 ±36.03mg / L, TCOD20.88±1.13g / L, pH 7.3. The remaining sludge directly enters the sludge hydrolysis acidification tank 3 through the regulating tank 1, the included angle between the baffle plate 5 and the vertical surface of the sludge hydrolysis acidification tank 3 is 20°, and the ratio of the height of the baffle plate 5 to the height of the tank body is 10%. The unit weight of the soft biological carrier fixed on the board is 1.8kg / m 3 , the length of the fiber bundle is 100mm, the diameter of the bundle is 0.45mm, the distance between the bundles is 15mm, and the porosity is >99%. Bottom 3cm; The ratio of the diameter of the fast stirrer 7 of the outer circulation weak alkali fast stirring tank 8 ...

Embodiment 3

[0029] The difference from Example 1 is that the excess sludge to be treated is taken from the sludge concentration tank of an urban sewage treatment plant, the sludge concentration is 53.17±2.04g / L, the concentration of volatile suspended solids is 27.19±1.43g / L, and the SCOD is 639.4 ±51.28mg / L, TCOD 39.62±2.91g / L, pH 6.8. The remaining sludge directly enters the sludge hydrolysis acidification tank 3 through the regulating tank 1, the included angle between the baffle plate 5 and the vertical surface of the sludge hydrolysis acidification tank 3 is 30°, and the ratio of the height of the baffle plate 5 to the height of the tank body is 10%. The unit weight of the soft biological carrier fixed on the board is 2.0kg / m 3 , fiber bundle length 80mm, bundle filament diameter 0.35mm, distance between bundles 25mm, porosity > 99%; mechanical stirring paddle 4 blade inclination angle is 45°, ratio of diameter to tank diameter is 0.8, distance from sludge hydrolysis acidification ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com