Conveyors for transporting goods

A technology for conveying devices and articles, applied in the directions of transportation and packaging, conveyor objects, sorting, etc., can solve problems such as vacuum pipeline blockage and suction device damage, and achieve the effect of eliminating vacuum supply, facilitating manufacturing, and compacting costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

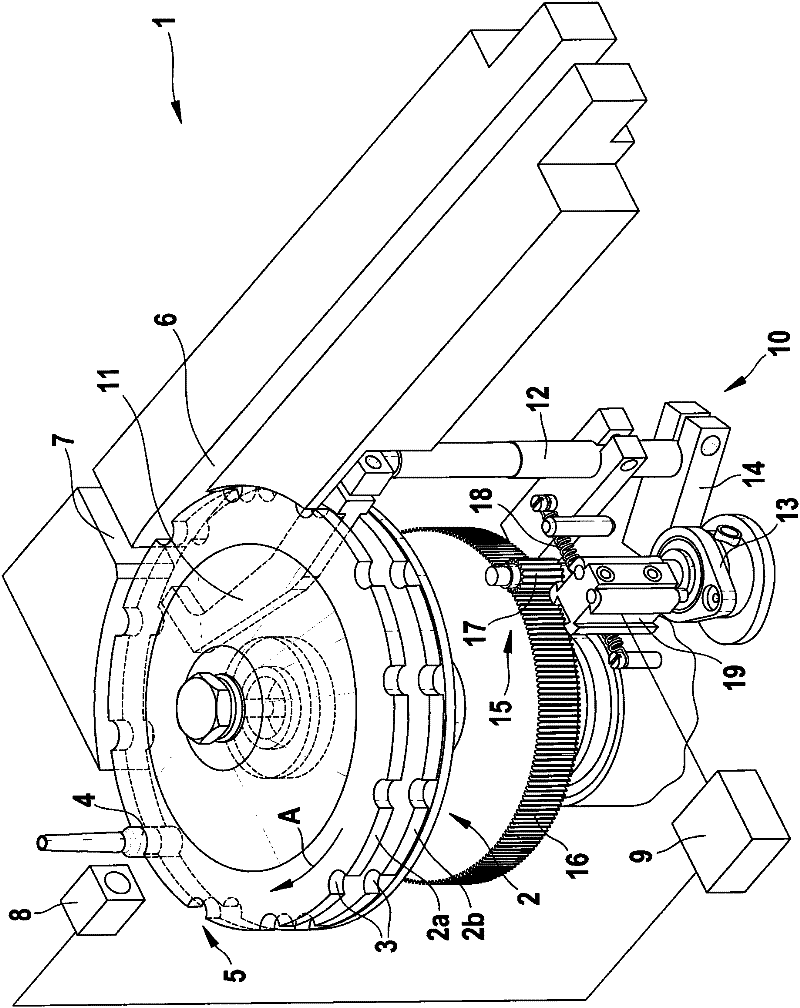

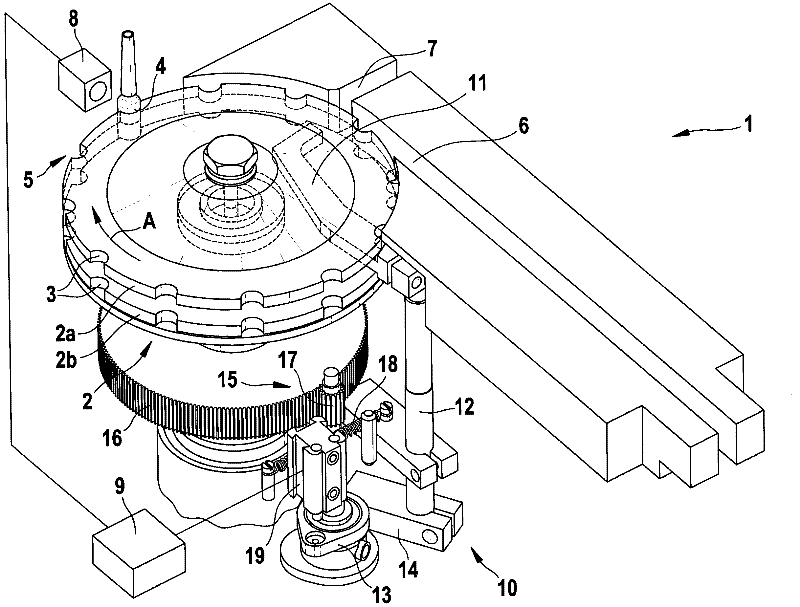

[0014] Refer below figure 1 A delivery device 1 according to a preferred embodiment of the present invention is described in detail.

[0015] Such as figure 1 As shown, the conveying device 1 comprises a conveying wheel 2 which is designed as a double wheel and comprises a first sub-wheel 2a and a second sub-wheel 2b. A plurality of recesses 3 are formed in each of the two sub-wheels 2 a , 2 b , which are arranged at the same position in the circumferential direction of the conveying wheel 2 . These recesses 3 serve here to receive objects 4 . exist figure 1 Only one item 4 is drawn in for clarity reasons. Also provided in the conveying wheel 2 is an inlet region 5 , in which the articles are fed to the conveying wheel 2 , and an outlet region 6 , in which the articles are discharged from the conveying wheel 2 .

[0016] The conveyor device 1 also includes a testing device 8 which performs a testing of the articles 4 . In particular, the item is checked with respect to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com