Stirring device for high-viscosity material

A stirring device, high-viscosity technology, used in mixers with rotary stirring devices, transportation and packaging, chemical/physical processes, etc., can solve problems such as difficult cleaning and no solution to stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

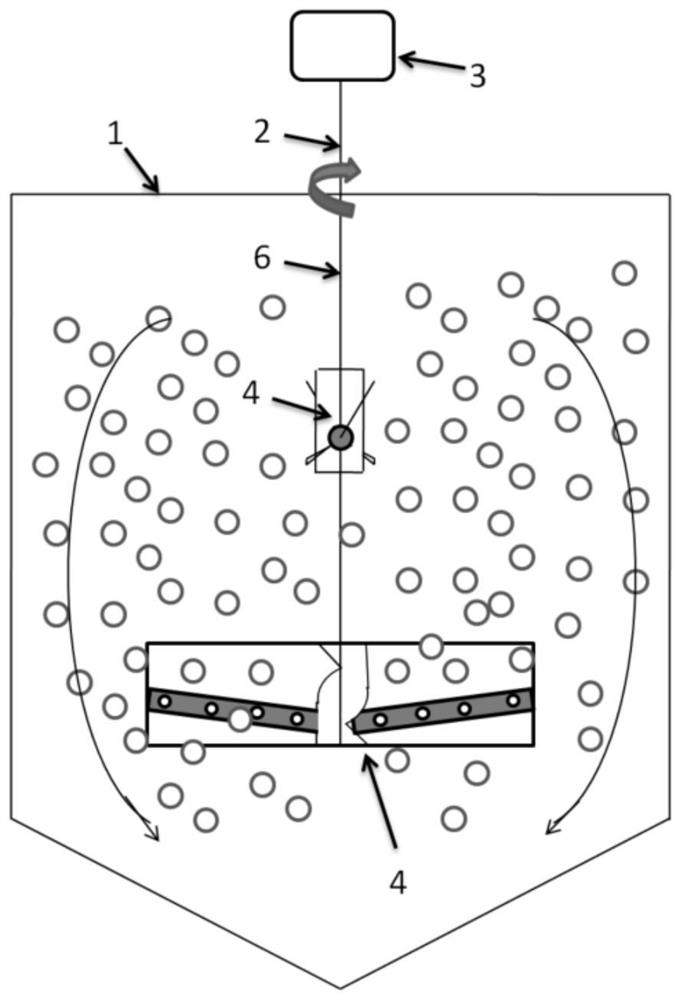

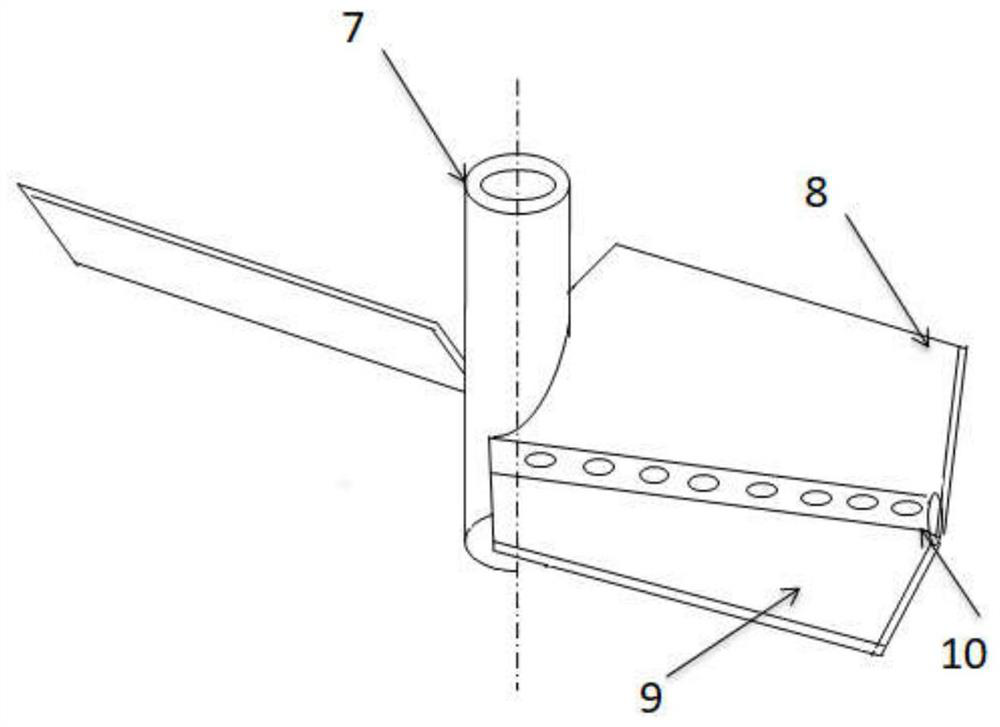

[0023] Such as figure 1 and figure 2 As shown, the stirring device for high-viscosity materials of the present embodiment includes a stirring tank 1 and an agitator 2, and the agitator 2 includes a drive motor 3, an air source (not shown in the figure), a rotating shaft 6, and a shaft arranged on the rotating shaft 6 Two stirring paddles 4, the two stirring paddles 4 are axially spaced apart along the rotating shaft 6, and each stirring paddle 4 includes two paddles, which are evenly distributed around the hub 7 along the circumferential direction, and in the axial direction, any stirring paddle The paddle is located in the middle of the two paddles of the adjacent stirring paddle.

[0024] The stirring tank 1 has a diameter of 1800 mm and a height of 1650 mm. Two stirring paddles 4 are respectively welded on the rotating shaft 6. The diameters from top to bottom are 1100 mm and 900 mm respectively, and the distance between the two stirring paddles is 500 mm.

[0025] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com