Liquid stirring oscillation device, application and liquid stirring method

An oscillation device and liquid technology, which is applied in the field of liquid stirring and liquid stirring oscillation device, can solve the problems such as inability to react to solution stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

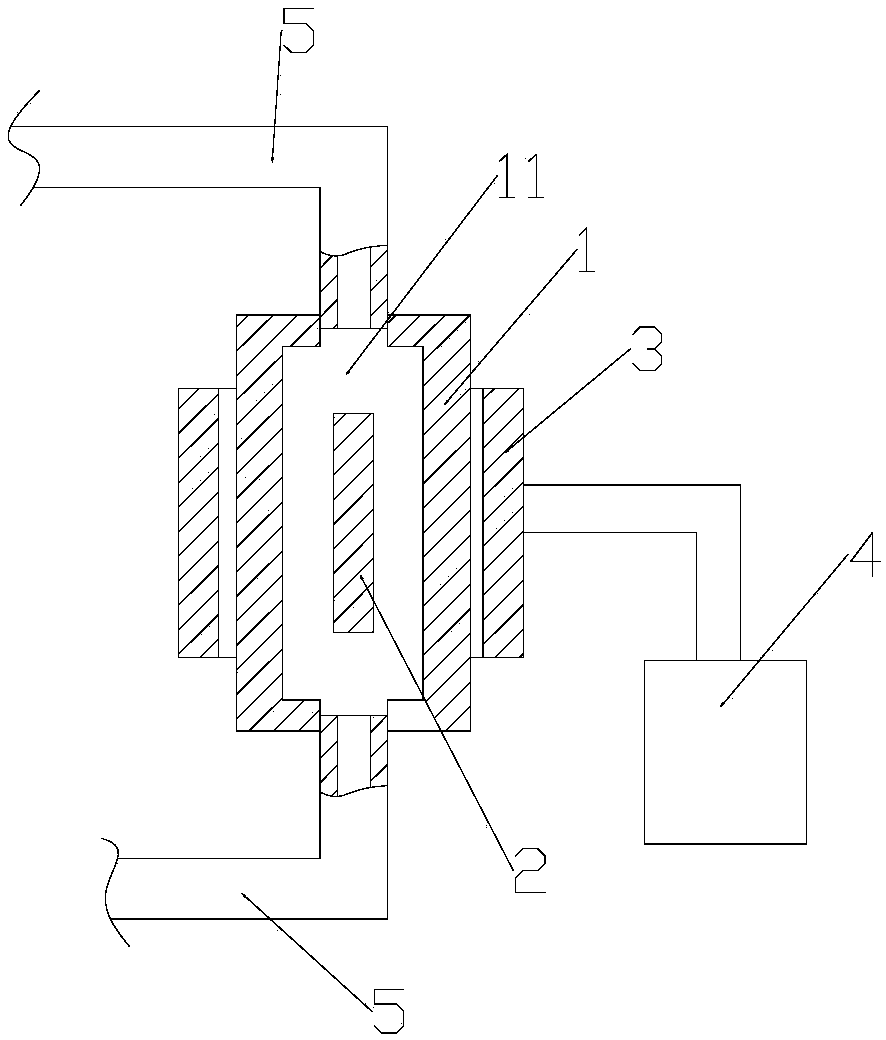

[0028] refer to figure 1 , this embodiment discloses an oscillating device for stirring a liquid, which is connected to a reactor (not shown in the figure) and stirs the liquid in the reactor. The oscillating device includes an isolation body 1 , an inner core 2 , a magnetic jacket 3 , a power source 4 and a connecting pipe 5 .

[0029] The isolator 1 is a columnar body made of Hastelloy, and a flow channel 11 is formed on the isolator 1 . In this embodiment, the isolator 1 is cylindrical, the flow channel 11 is linear, and the flow channel 11 is arranged coaxially with the isolator. The inner core 2 is cylindrical and located in the flow channel 11 .

[0030] The magnetic jacket 3 is a hollow cylinder whose inner diameter is adapted to the outer diameter of the separator 1 ; the magnetic jacket 3 is sheathed on the outer surface of the separator 1 and attracts the inner core 2 .

[0031] The power source 4 is connected with the magnetic jacket 3 to drive the magnetic jacke...

Embodiment 2

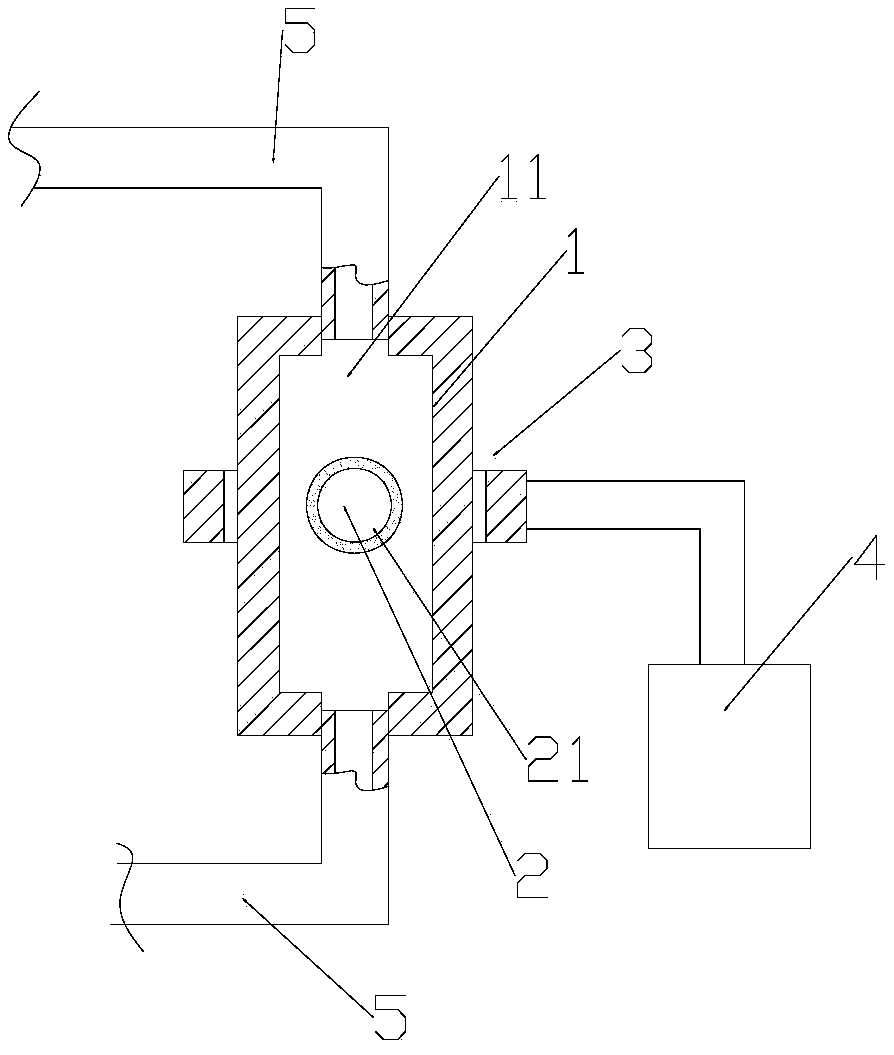

[0039] refer to figure 2 The difference between this embodiment and embodiment 1 is that the inner core 1 is spherical, and its surface is provided with a corrosion-resistant layer 21, which is made of polytetrafluoroethylene material, so as to prevent the inner core 2 from being corroded. and pollute the liquid; the magnetic jacket 3 is in the shape of a ring.

Embodiment 3

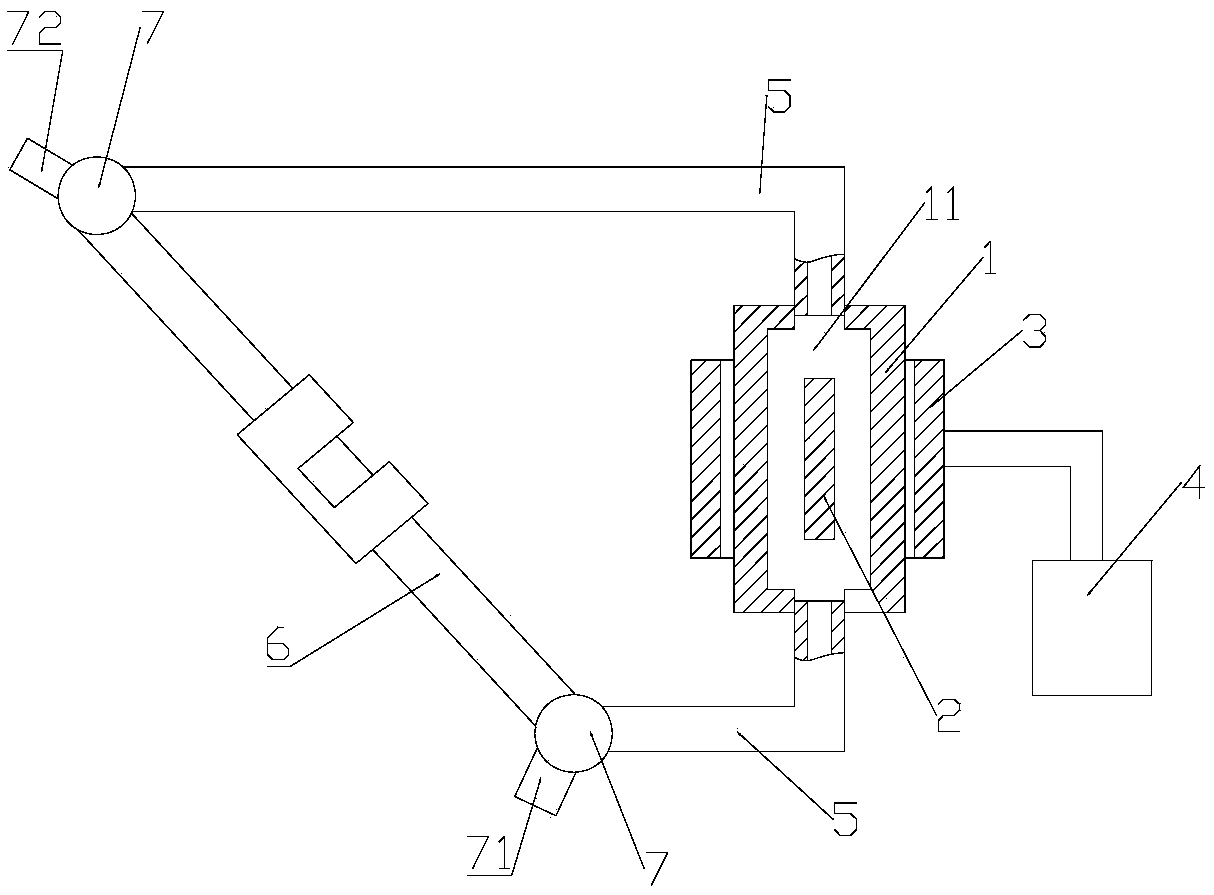

[0041] The capillary 6 with a diameter of about 1 mm is often used as a liquid sample detection cell in the field of X-ray measurement, and the liquid in it needs to be stirred in order to increase the experimental signal intensity during the detection process. In this embodiment, the oscillating device described in Embodiment 1 is used to realize the stirring of the liquid in the capillary 6 .

[0042] refer to image 3 , the end of the capillary 6 is connected to the connection pipeline 5 respectively by two three-way valves 7, and a sample inlet 71 is set at one three-way valve 7, and a sample outlet 72 is set at another three-way valve 7, of course, When stirring, both the sample inlet 71 and the sample outlet 72 are closed. After the reaction solution fills the channel 11, the linear motor is turned on to vibrate and stir the reaction solution in the capillary 6.

[0043] During the experiment, it can be determined whether to pressurize or locally heat the liquid in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com