Automatic grouting and stirring system

A stirring system and automatic grouting technology, which are used in mixer accessories, mixers with rotating stirring devices, and dissolution, etc., can solve the problems of inability to adjust the proportion of slurry in time, inaccurate adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

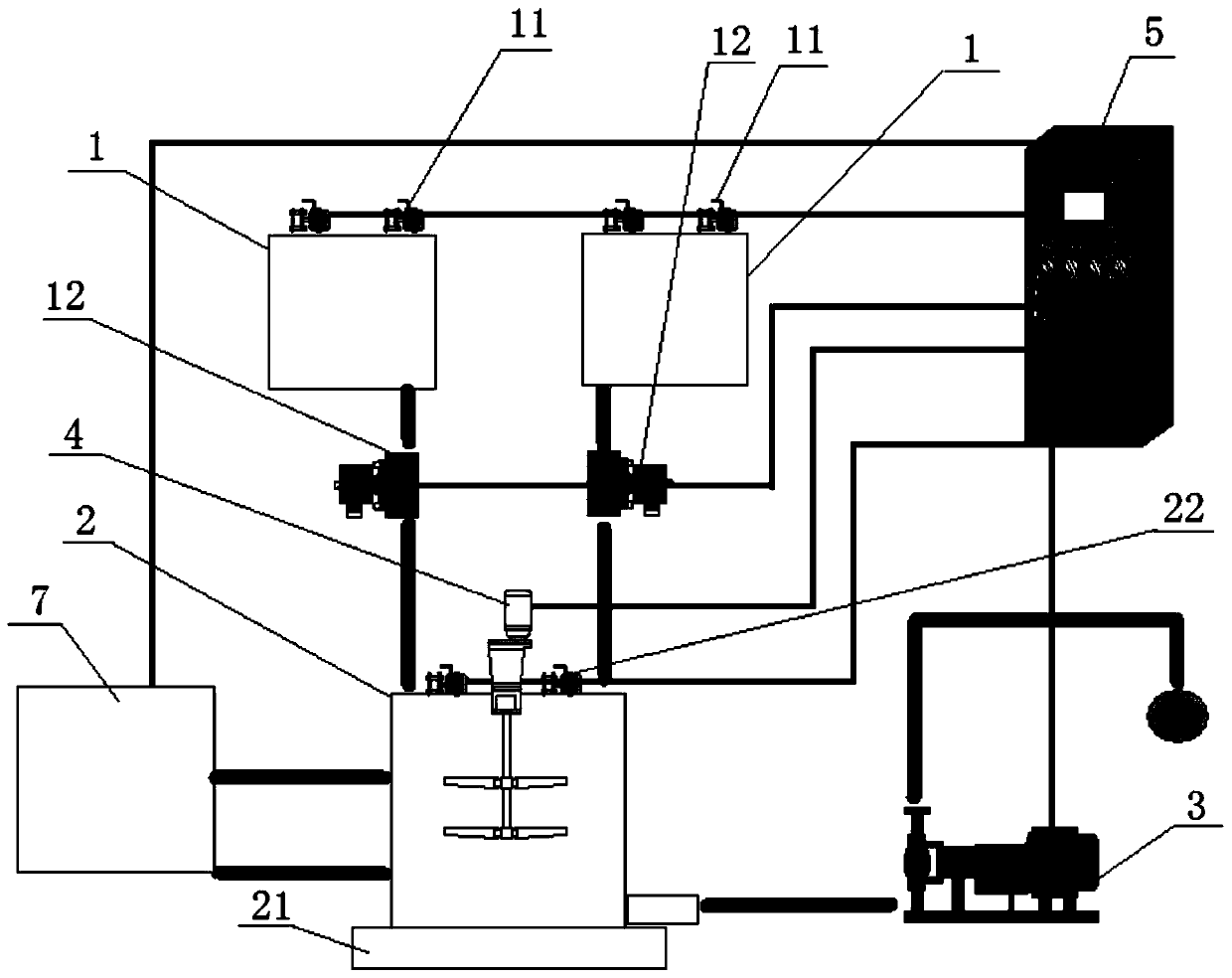

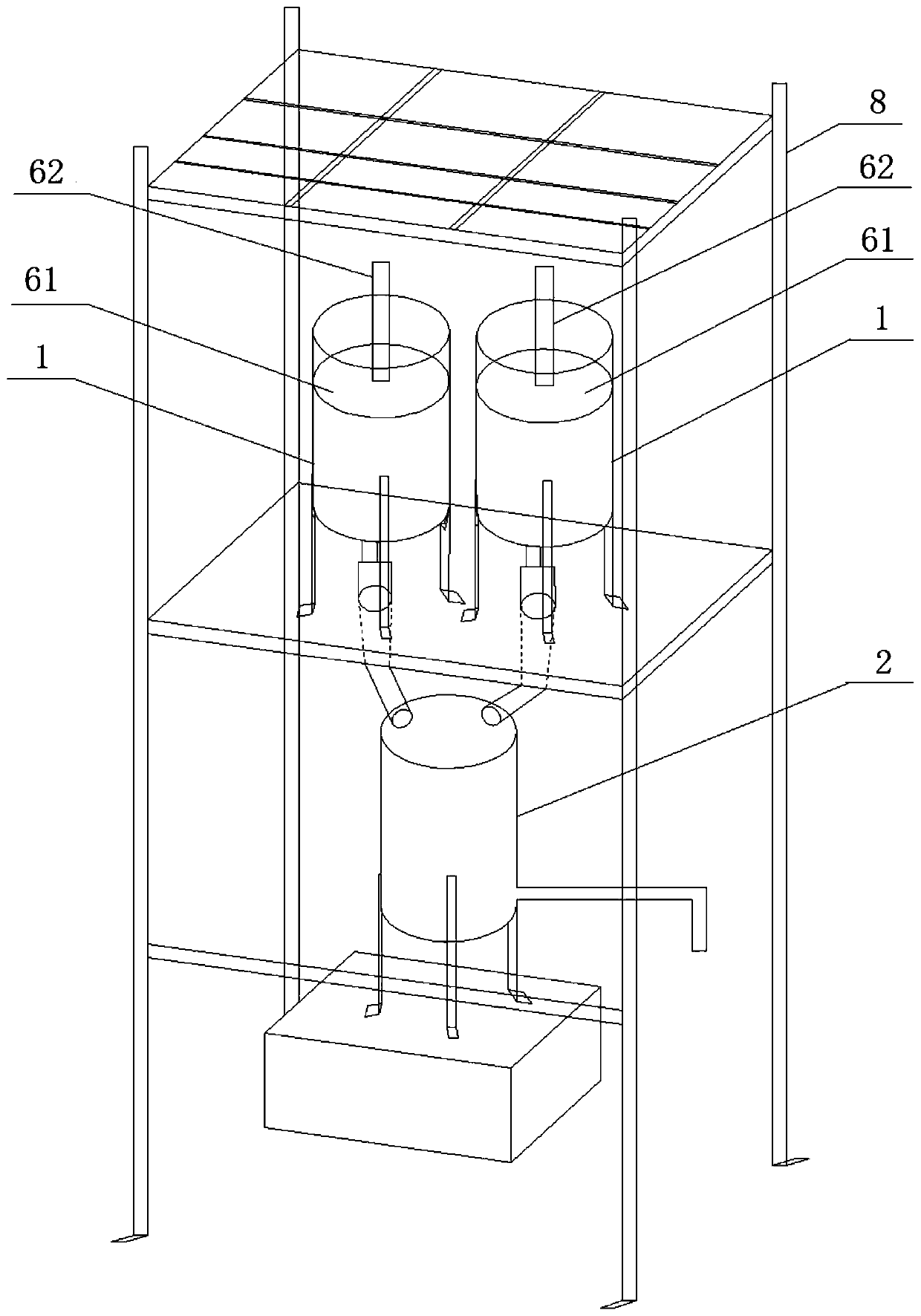

[0012] Such as figure 1 As shown, Embodiment 1 of the present invention provides an automatic grouting mixing system, hereinafter referred to as the system, including at least two raw material barrels 1, a mixing barrel 2, a mixer 4, a grouting pump 3 and a host computer 5, and each of the raw material barrels 1 There are discharge ports on the top, and a feed port is provided on the mixing barrel 2, each of the discharge ports is located above the feed port, and each of the discharge ports is connected to the feed port respectively. , flow valves 12 are installed on each of the discharge ports, a liquid level sensor 11 is installed in each of the raw material barrels 1, the mixer 4 is arranged in the mixing barrel 2, and the mixing barrel 2 is placed in the electronic On the scale 21, the mixing tank 2 is communicated with the grouting pump 3, each of the flow valves 12, the grouting pump 3, the mixer 4, each of the liquid level sensors 11 and the electronic scale 21 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com