Automatic liquor processing machine

An automatic processing and liquor technology, applied in the field of Maotai-flavor liquor processing, can solve the problems of reducing processing efficiency, time-consuming, inconvenient use, etc., and achieves the effects of reasonable device structure, improved processing efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

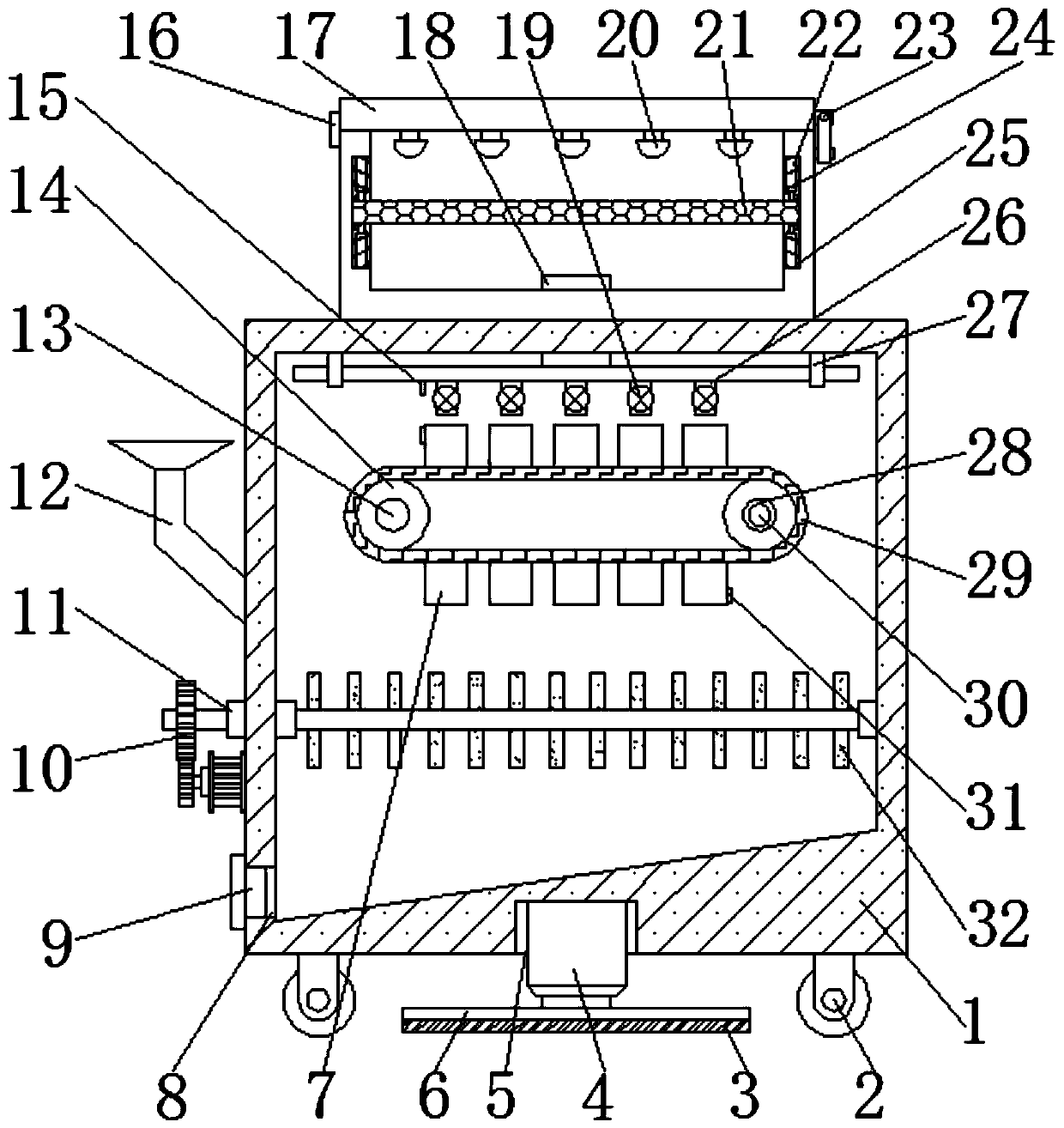

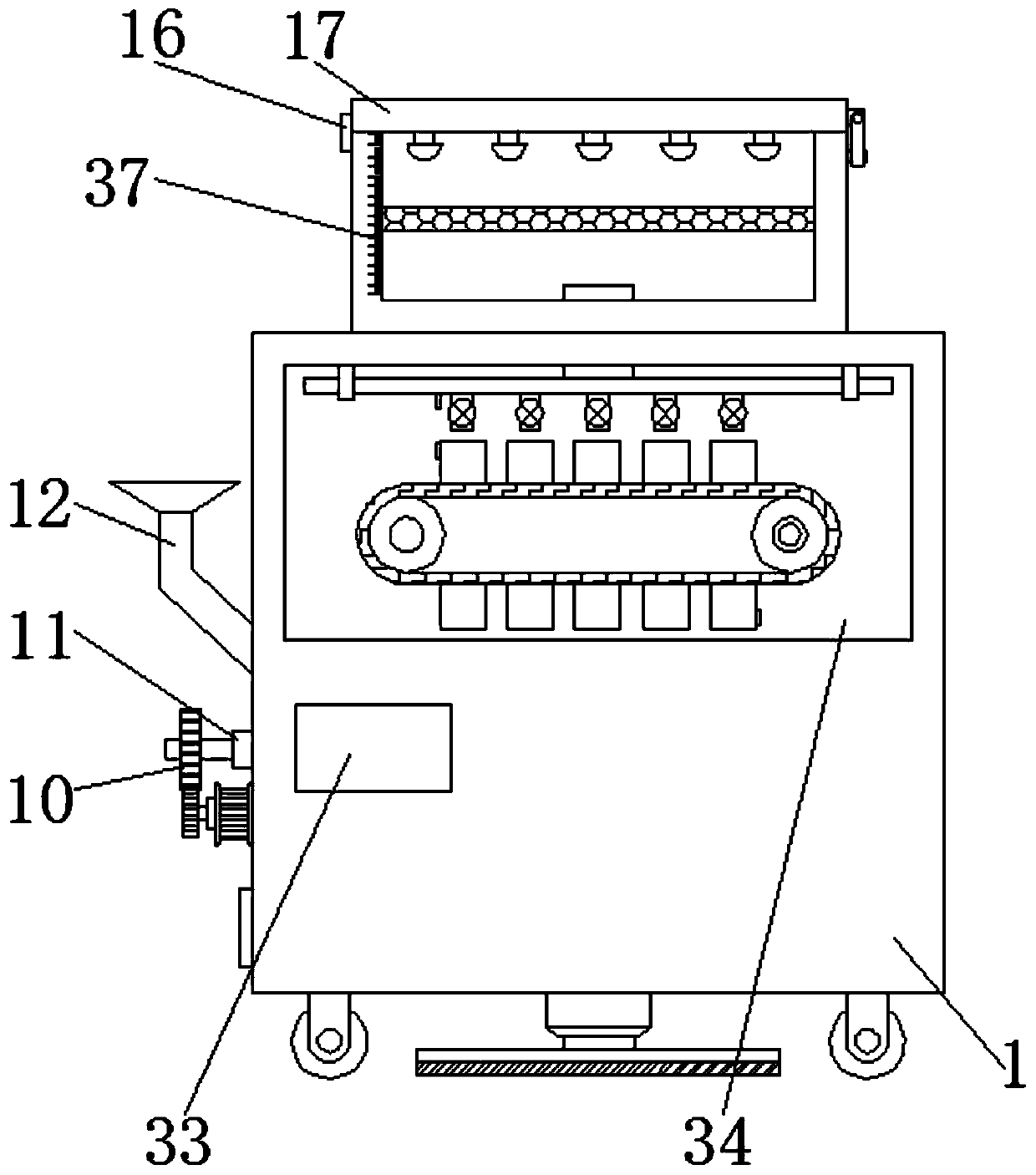

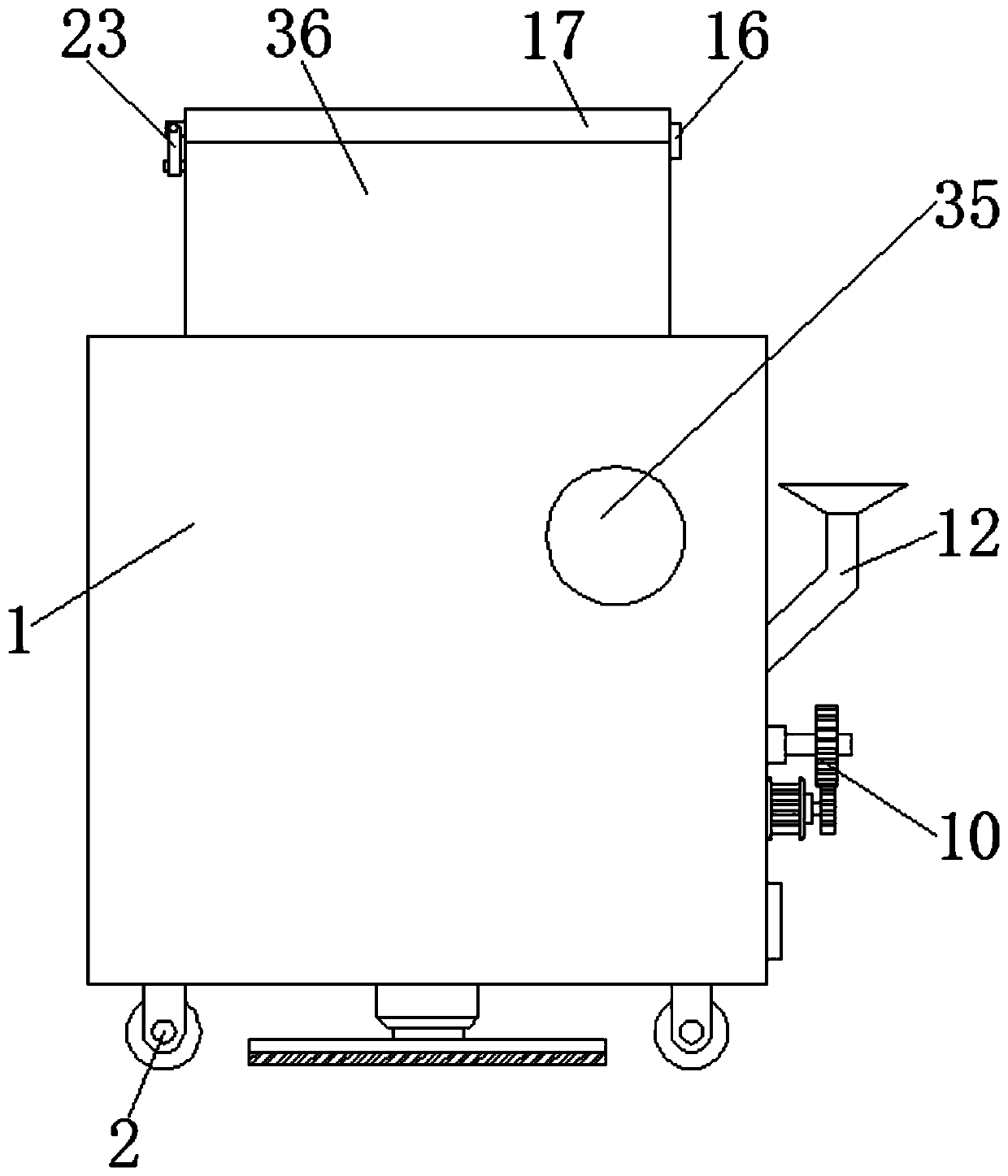

[0024] see Figure 1-5 The present invention provides the following technical solutions: an automatic processing machine for liquor, comprising a housing 1, a storage tank 36 is fixedly connected to the top of the housing 1, and a second recess is provided on the side of the inner wall of the storage tank 36. Groove 25, the top and bottom of the inner wall of the second groove 25 are fixedly connected with a telescopic assembly 22, the surface of the telescopic assembly 22 is sleeved with a spring 24, and the opposite ends of the two telescopic assemblies 22 and spring 24 are fixed A filter screen 21 is connected, and the separated ends of the two springs 24 are fixedly connected to the inner wall of the second groove 25, and the top of the storage tank 36 is movably connected with a cover plate 17 through a hinge 16, and the cover plate 17 The side of the cover plate 17 is fixedly connected with the housing 1 through the lock 23, and the bottom of the cover plate 17 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com