Slurry-bed hydrocracking high pressure hot separator with cyclone separators

A technology of hot high-pressure separator and cyclone separator, which is applied in the direction of the device where the axial direction of the swirl can be reversed, the swirl device, etc., can solve the problem of poor separation effect of the hot high-pressure separator, and avoid coking or clogging, Anti-clogging and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

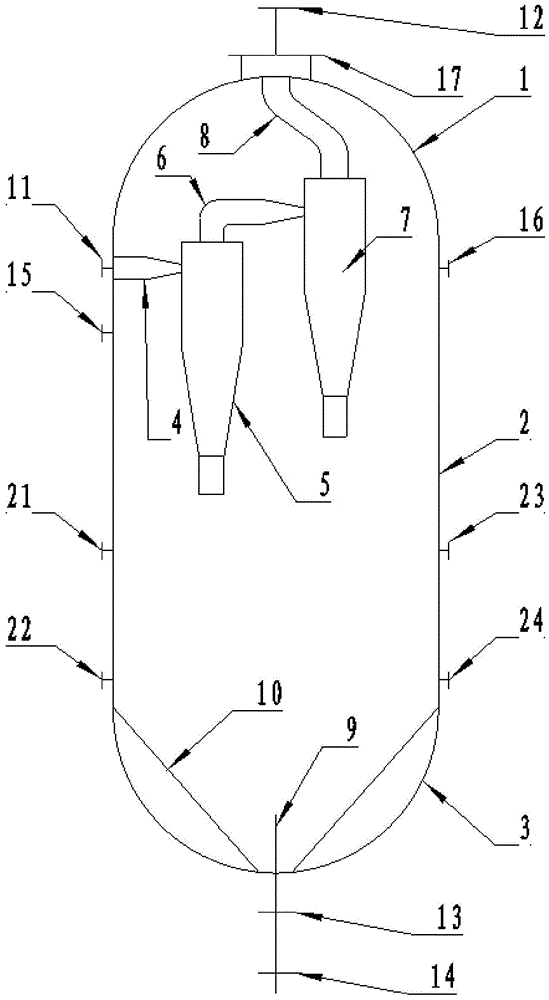

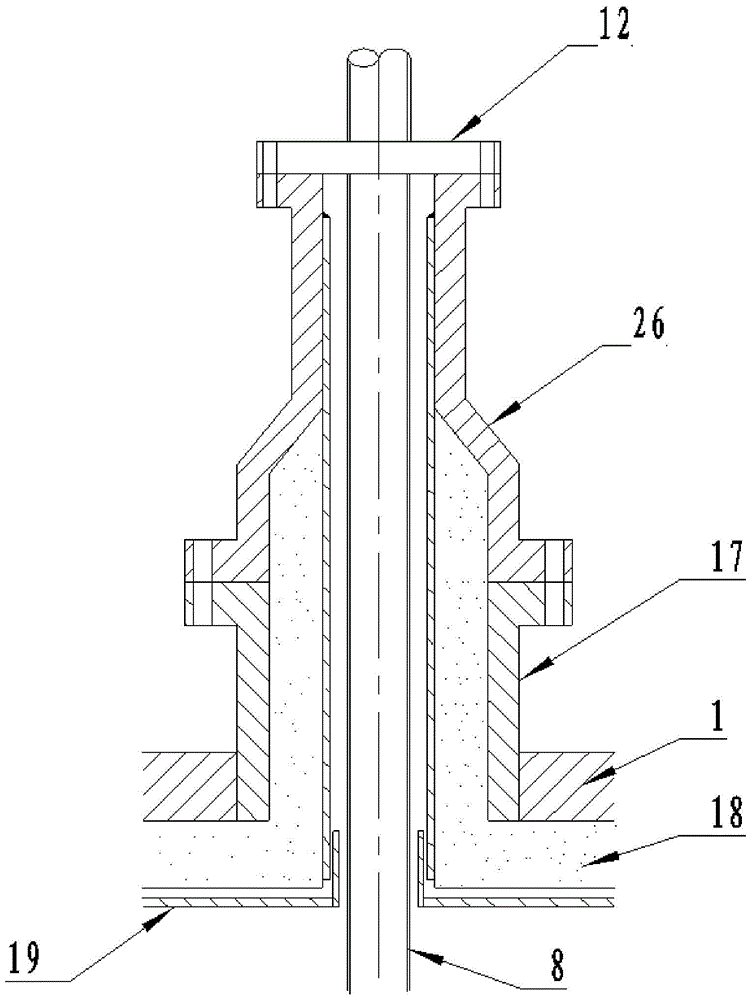

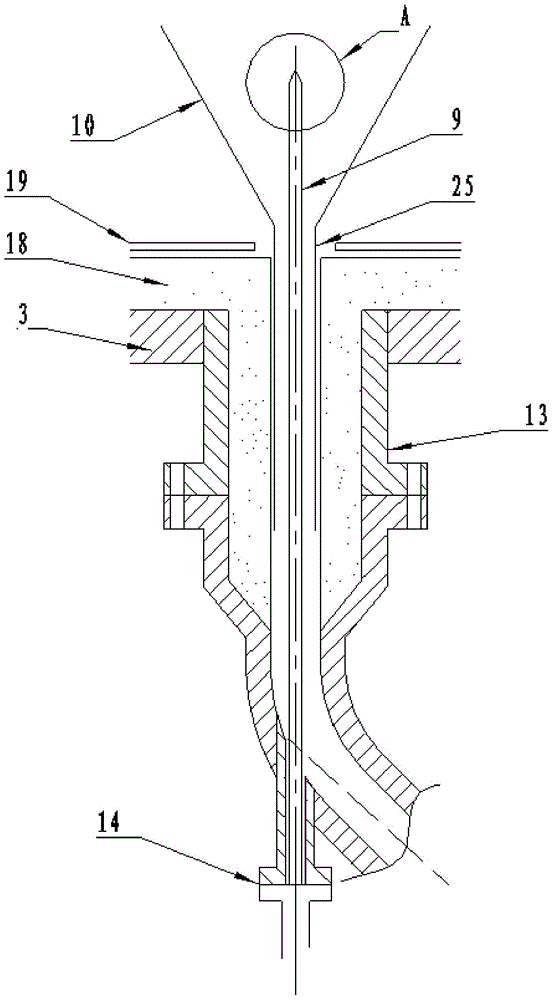

[0037] A hot high-pressure separator for suspended bed hydrogenation with rotary separation, comprising a shell, the shell is cylindrical in shape with both upper and lower ends closed, and a reaction chamber for injecting the suspended bed reaction product into the shell is provided outside the shell. Product inlet 11, the shell is also provided with a hot high-separation gas outlet 12 for discharging the hot high-separation gas in the shell, and the lower part of the shell is provided with a hot high-separation liquid for discharging the hot high-separation liquid in the shell Outlet 13 is connected with two cyclone separators successively between reaction product inlet 11 and hot high fracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com