Evaporation wall-type supercritical water oxidation reactor capable of directly separating salt and subcritical water

A technology of supercritical water oxidation and subcritical water, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of pipeline blockage, difficult separation of salt and subcritical water, restricting development, etc., and achieve the effect of reducing material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

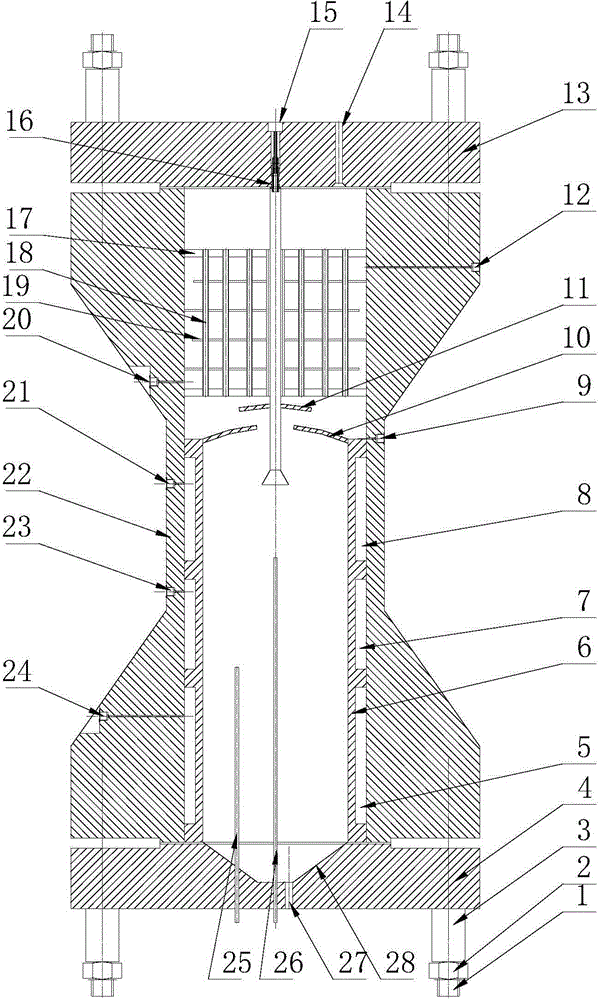

[0026] An evaporating wall supercritical water oxidation reactor capable of directly separating salt and subcritical water, which mainly consists of a cylinder 22, an upper end cover 13, a lower end cover 4, a burner assembly 16, a shell-and-tube heat exchanger, a multilayer The evaporation wall 6 constitutes. The cylinder body, the upper end cover and the lower end cover are fixed with high temperature resistant bolts 1 and nuts 2, and a high temperature resistant sleeve 3 is used to ensure the fastening force of the nuts under high temperature.

[0027] The middle part of the upper end cover is installed with a burner assembly extending into the inside of the cylinder, and the upper end cover is formed with a gas phase outlet 14 and a secondary sewage i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com