Supercritical 145MW-grade primary intermediate reheating reaction steam turbine

A supercritical, reactionary technology, applied in steam engine devices, engine components, machines/engines, etc., can solve the problems of low cycle efficiency and low efficiency of small and medium-sized steam turbine cylinders, and achieve improved cycle efficiency, high safety, and reduced construction costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

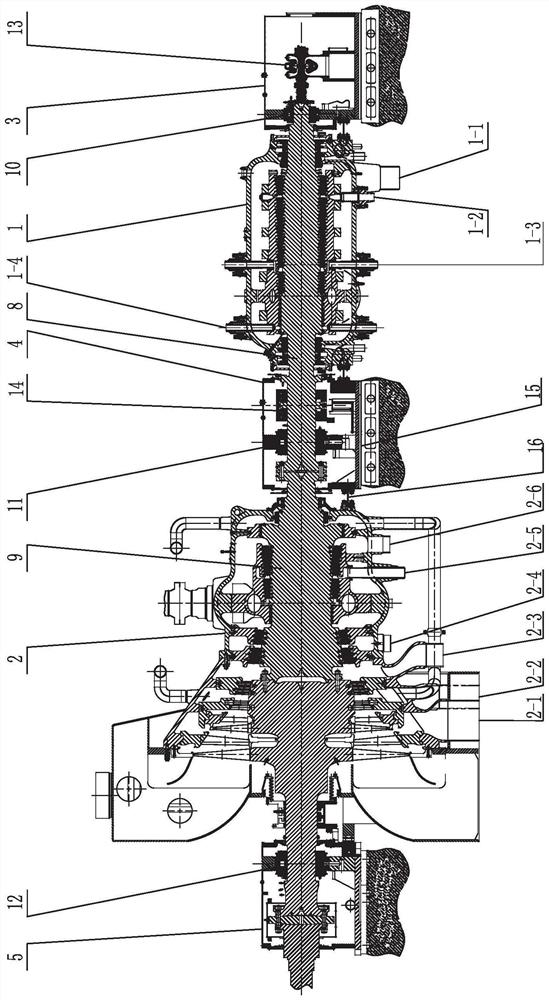

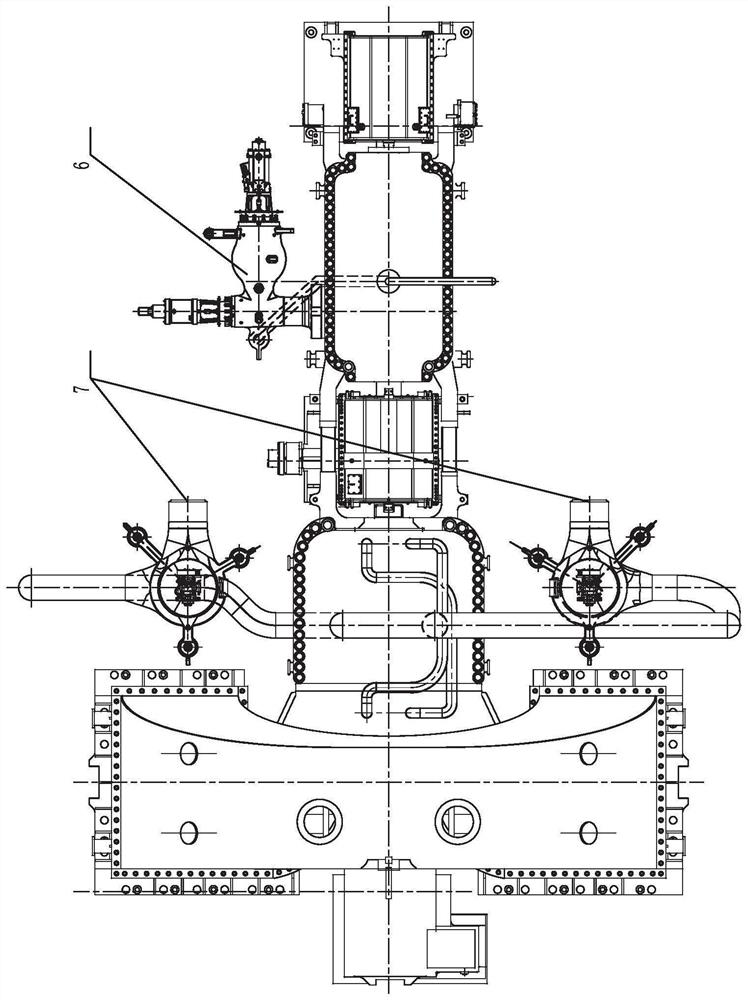

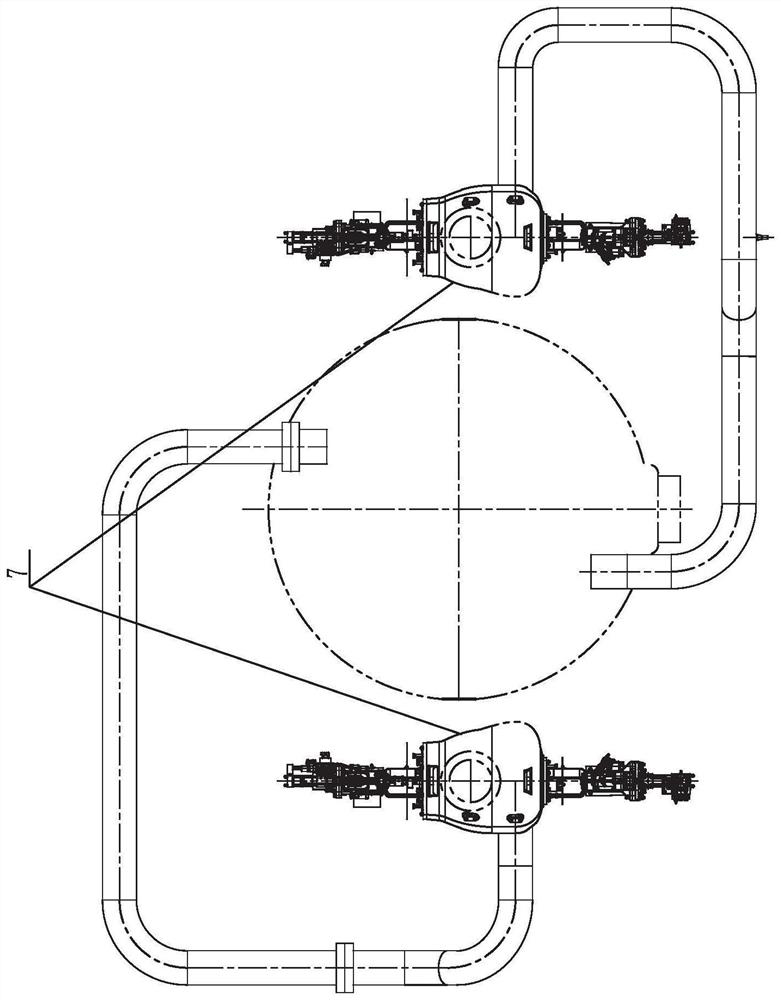

[0026] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment mode, a supercritical 145MW level one-time intermediate reheat reaction steam turbine described in this embodiment mode, which includes a high-pressure cylinder 1, a medium-low pressure cylinder 2, a front bearing box 3, a middle bearing box 4, a rear bearing box 5, High pressure rotor 8, medium and low pressure rotor 9, first bearing 10, second bearing 11, third bearing 12, main oil pump 13, thrust bearing 14 and two sliding mechanisms 15, medium and low pressure rotor 9 and high pressure rotor 8 from left to The right is connected sequentially, the medium and low pressure cylinder 2 is set on the medium and low pressure rotor 9, the high pressure cylinder 1 is set on the high pressure rotor 8, the electric end of the medium and low pressure rotor 9 is set with the third bearing 12, the electric end and the adjustment end of the high pressure rotor 8 are respectively The second bearin...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination figure 1 To illustrate this embodiment, two high-pressure steam intake ports 1-3 and two balance hub steam leakage ports 1-4 are installed on the high-pressure cylinder 1 described in this embodiment, and the two high-pressure steam intake ports 1-3 are installed symmetrically On the top and bottom of the high-pressure cylinder 1, two balance hub steam leakage ports 1-4 are symmetrically installed on the top and bottom of the high-pressure cylinder 1, and the bottom of the high-pressure cylinder 1 is provided with a high-pressure steam exhaust port 1-1 and a No. 1 steam extraction port 1-2, balance hub steam leakage port 1-4, high-pressure steam supply port 1-3, No. 1 steam extraction port 1-2 and high-pressure steam exhaust port 1-1 are close to the first bearing from left to right 10 settings. The two balance hub steam leakage ports 1-4 are connected to the steam turbine bypass system to lead out the high-temperature stea...

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the bottom of the middle and low pressure cylinder 2 described in this embodiment is provided with No. 8 steam extraction port 2-1, No. 7 steam extraction port 2-2, No. 6 steam extraction port 2-3, No. 5 steam extraction port 2-4, No. 3 steam extraction port 2-5 and No. 4 steam extraction port 2-6.

[0033] Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com