Dynamic photo-bio-reactor and method for culturing microalgae by utilizing dynamic light

A technology of photobioreactor and photoculture, applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., which can solve the problem of low yield and poor microalgae cultivation environment, etc. problem, to achieve the effect of increasing production, saving labor costs, and solving cell sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for cultivating microalgae using dynamic light. When cultivating microalgae, the culture solution of microalgae is stirred in a rotating and lifting manner, and dynamic light synchronous with stirring is used during stirring, that is, when stirring During the process, the position and angle of the light change synchronously with the rotation and lifting actions.

[0034] As mentioned above, the essence of microalgae culture is the conversion of light energy, and light is the key factor for the growth of microalgae. The quality of light conditions also has a crucial impact on the production of microalgae. By fully stirring the microalgae and changing the angle and direction of the light received by the microalgae at all times, the microalgae in different positions can receive more uniform light. , and form the turbulence required for microalgae cultivation by stirring, optimize the cultivation environment of microalgae, and increase the ...

Embodiment 2

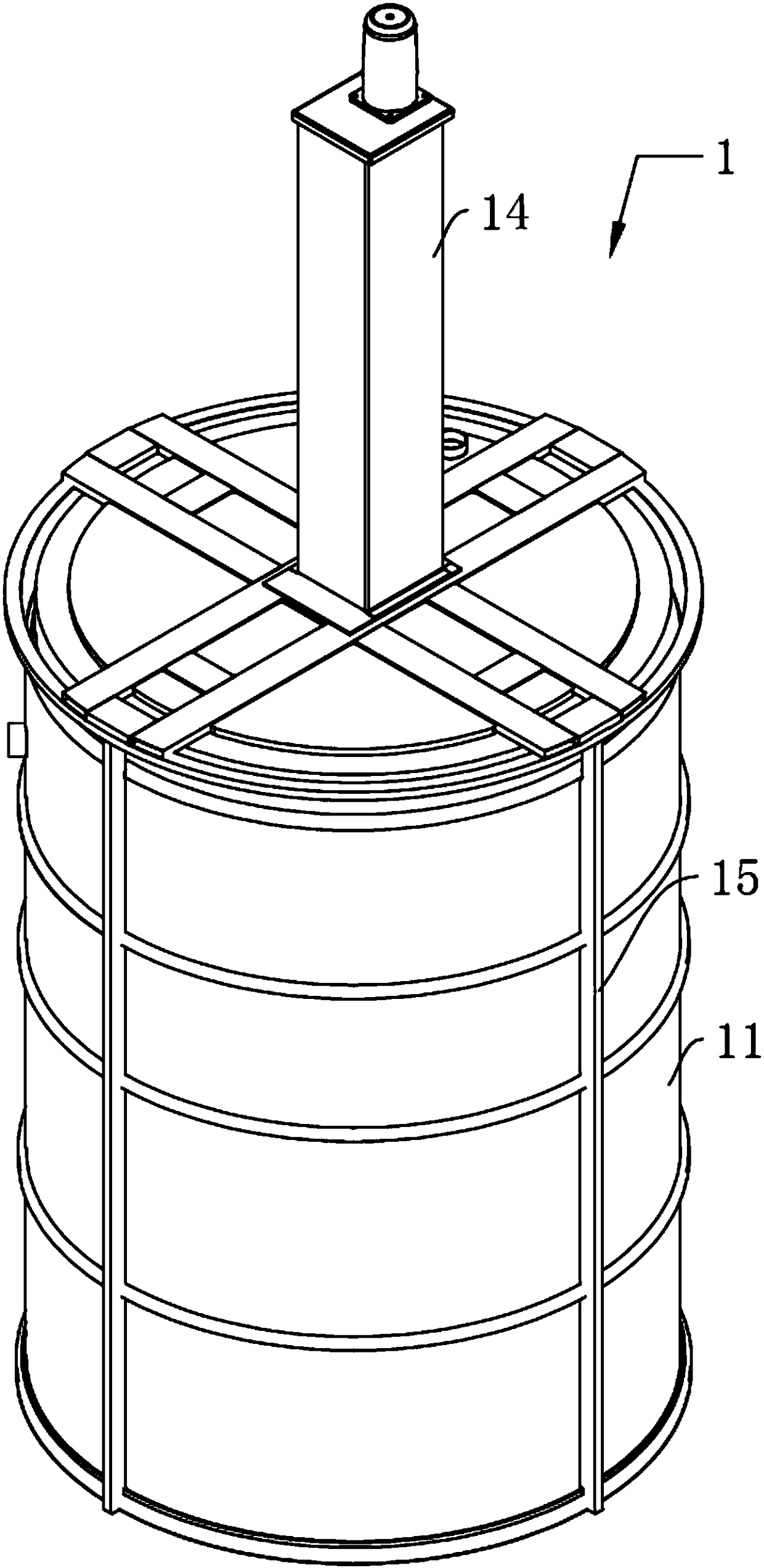

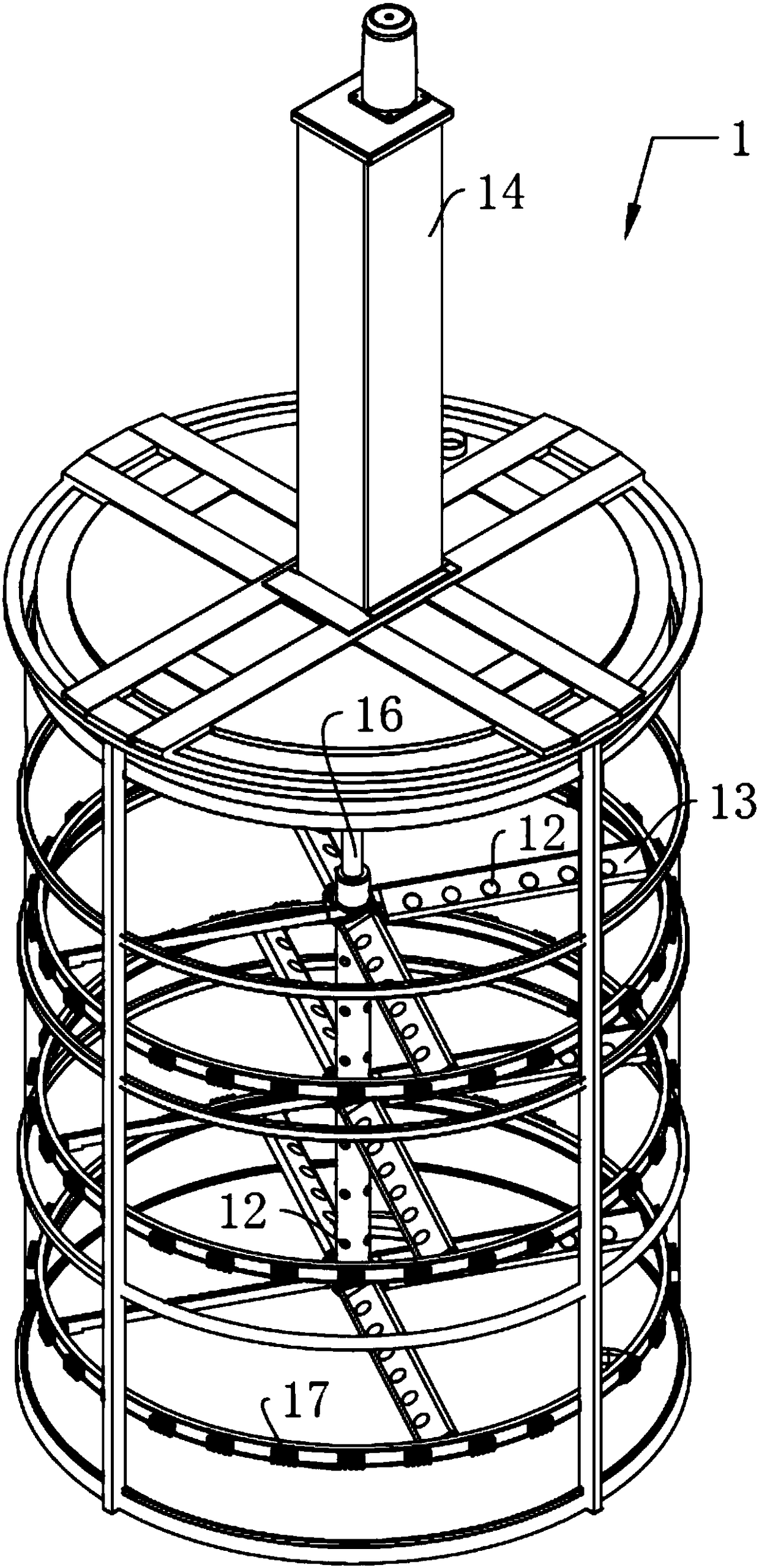

[0039] figure 1 An overall structural axonometric view of the dynamic photobioreactor 1 is shown, figure 2 An axonometric view of the internal structure of the overall structure of the dynamic photobioreactor 1 is shown.

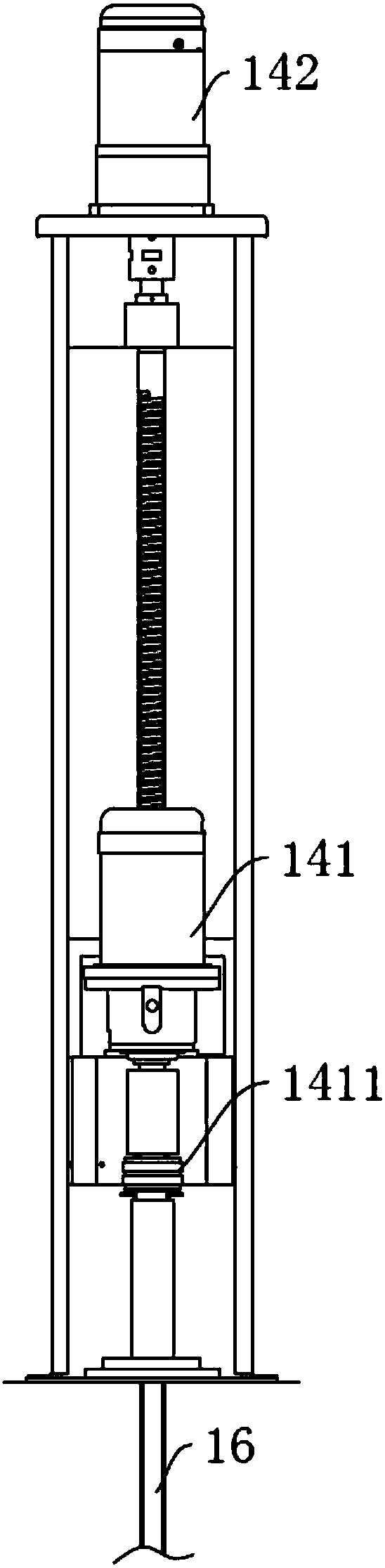

[0040] This embodiment provides a dynamic photobioreactor 1 , which includes a culture tank 11 , a light emitting unit 12 , light arm paddles 13 and a driving mechanism 14 . The light-emitting unit 12 is arranged on the light arm paddle 13, and the light arm paddle 13 is set in the culture tank 11, and the driving mechanism 14 can drive the light arm paddle 13 to rotate and lift.

[0041] As mentioned above, the dynamic photobioreactor 1 is used to cultivate microorganisms, and this embodiment takes the cultivation of microalgae as an example.

[0042] The cultivation tank 11 is a reaction vessel for cultivating microalgae, which is cylindrical in shape and can be made of light-transmitting material. After passing through the cultivation tank 11, natural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com