Material conveying device provided with screw shaft spreading mechanism as well as material conveying channel

A conveying device and conveying channel technology, which is applied in the field of material drying equipment, can solve the problems of material adhesion, material accumulation, and easy adhesion of materials to the board wall, and achieve the effect of preventing wall hanging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

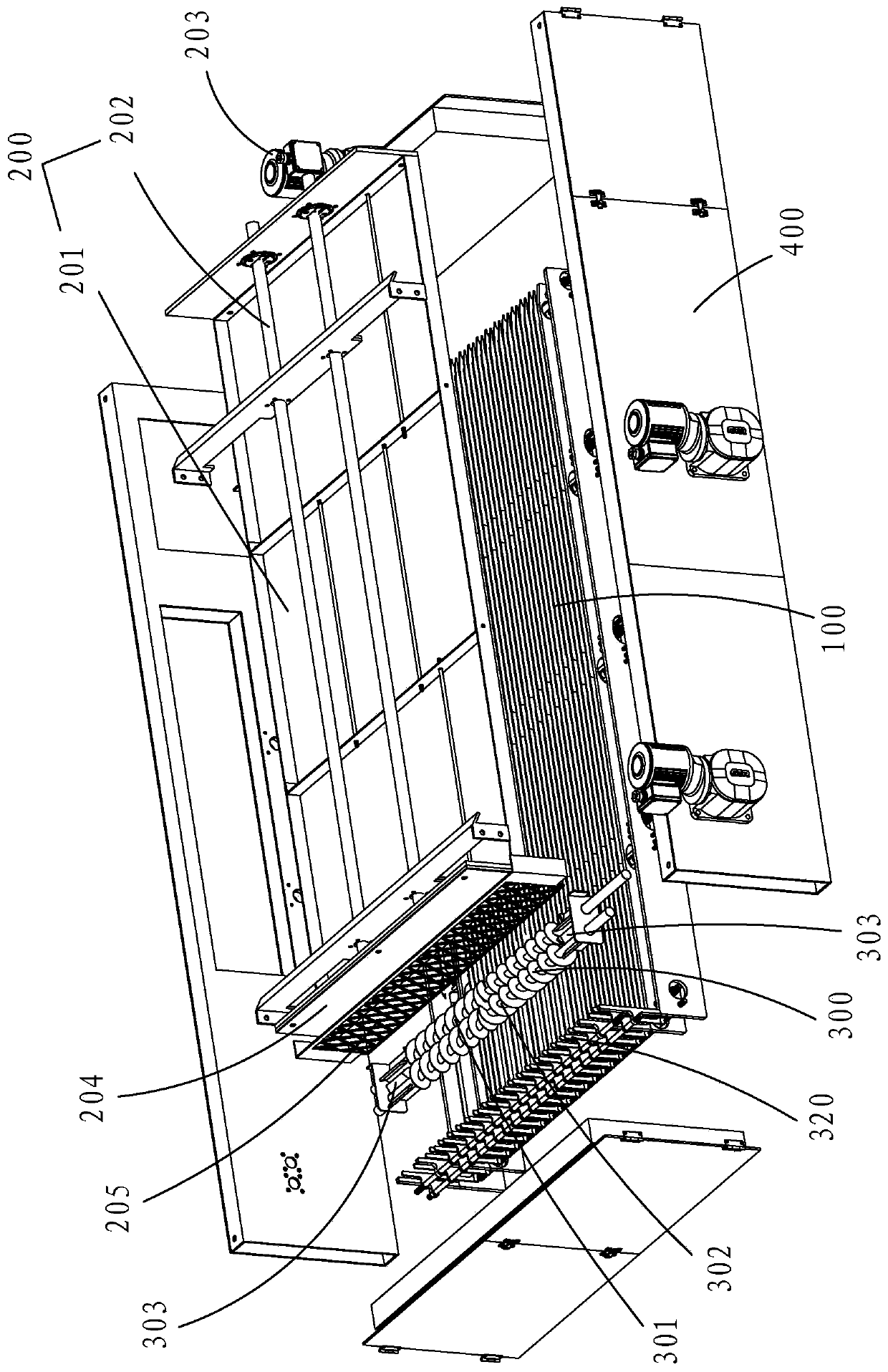

[0024] Such as figure 1 As shown, a material conveying device with a spiral shaft material spreading mechanism includes a stacked strip push-type material conveying platform 100, a spiral shaft material spreading mechanism 300 located above the beginning of the conveying platform 100, and the spiral shaft material spreading mechanism 300. The material rolling device 200 is provided above the conveying platform 100 on one side of the mechanism 300 toward the material conveying direction.

[0025] The driving method of the conveying platform 100 is the same as that of the stacked push-type material conveying platform of Chinese invention 201911093469.3 (hereinafter referred to as "comparison document"). The first motor 101 drives the conveying platform 100 to perform a reciprocating synchronous circular motion to carry and propel the material forward;

[0026] The material rolling device 200 includes: a rolling platform 201 and a rolling driving mechanism 202 . The specific wo...

no. 2 example

[0037] As another embodiment of the present invention: a material conveying channel for conveying materials from top to bottom, comprising at least two side walls facing each other; wherein at least one side wall is formed by stacking two groups of grid bar assemblies alternately. As a result, at least one group of grid bar components performs reciprocating synchronous circular motion. The specific structure and working principle of the side wall composed of the grid bar assembly in this embodiment are the same as those of the stacked bar push-type material conveying platform in the reference document. Due to the reciprocating movement of the bars, such a material conveying channel prevents material from accumulating on the side walls. It can also be, wherein at least one side wall is two boards arranged in parallel and close to each other, one board close to the material is a hollow board, and the other board is a sealing board, and the hollow board or the sealing board is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com