Process method and system for production of alpha-olefin by oligomerization of selective ethylene

An ethylene oligomerization and process method technology, applied in the production of bulk chemicals, chemical instruments and methods, hydrocarbons, etc., can solve the problems of hindering heat transfer, reducing the flow rate of system materials, increasing the frequency of shutdowns and maintenance costs, etc. Achieve the effect of improving plant efficiency, reducing maintenance costs, avoiding polymer wall hanging and plant downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

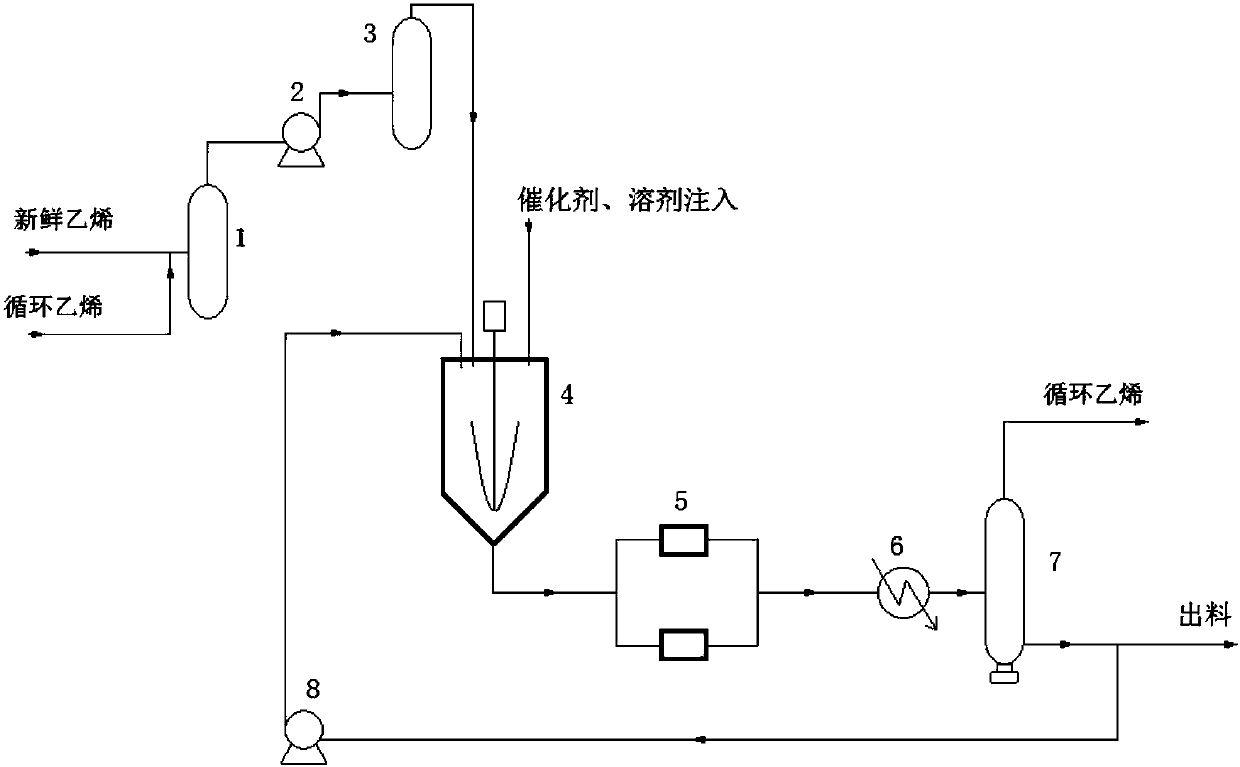

[0035] like figure 1 The shown selective ethylene oligomerization system for producing α-olefins includes a high-pressure reactor 4, a raw material device and a catalyst device, and the raw material device and the catalyst device are respectively connected to the high-pressure reactor. The raw material device consists of a mixing tank 1, a compressor 2 and a pressure stabilizing tank 3 which are sequentially connected by pipelines along the gas flow direction. The high-pressure reaction kettle 4 is a stainless steel vessel, and there is a jacket circulating water outside the vessel to provide heating / cooling. The high-pressure reactor 4 is provided with a material circulation pipeline. The feed end of the material circulation pipeline is connected to the bottom outlet of the high-pressure reactor 4, and the discharge end is connected to the top of the high-pressure reactor. The material circulation pipeline follows the fluid flow direction in sequence Two parallel bag filters...

Embodiment 2

[0037] like figure 1As shown, the volume of the high-pressure reactor is 0.5 cubic meters, and the volume of the gas-liquid separator is 0.1 cubic meters. The catalyst and co-catalyst are pre-prepared and dissolved in toluene at a ratio of 1:300, and the solubility of the catalyst is 60 μmol / L (calculated as chromium). The reaction system was replaced with 6MPa nitrogen for more than 3 times, and the pressure was released to 0.1MPa. Inject 180L of catalyst solution into the autoclave through a metering pump, and open the valve at the bottom of the autoclave until the liquid level in the gas-liquid separator reaches 20%. Open the valve at the bottom of the gas-liquid separator, turn on the circulation pump, establish the circulation of the catalyst liquid, and turn on the high-pressure reactor to stir. Increase the opening of the valve at the bottom of the high-pressure reactor and the valve at the bottom of the separator, increase the working efficiency of the circulation pu...

Embodiment 3

[0041] Consistent with Example 1, but when the liquid level in the autoclave reaches 60%, open the discharge port for continuous discharge, control the discharge rate to 45L / h, and control the catalyst solution to continuously feed to high pressure reaction at 22.5L / h in addition in the cauldron.

[0042] In this experimental example, the reaction was carried out for 72 hours, the average activity of the catalyst was 1670Kg oligomer / (mol·Cr·h), and 18.0Kg oligomer could be obtained per hour. The proportion of 1-hexene in the oligomer is about 33%, and the proportion of 1-octene is about 58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com