Stirring device and container for preparing colloid class plasma solubilizer

A technology of stirring device and solubilizing agent, which is applied in the direction of mixer with rotating stirring device, dissolution, transportation and packaging, etc., and can solve problems affecting product qualification rate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

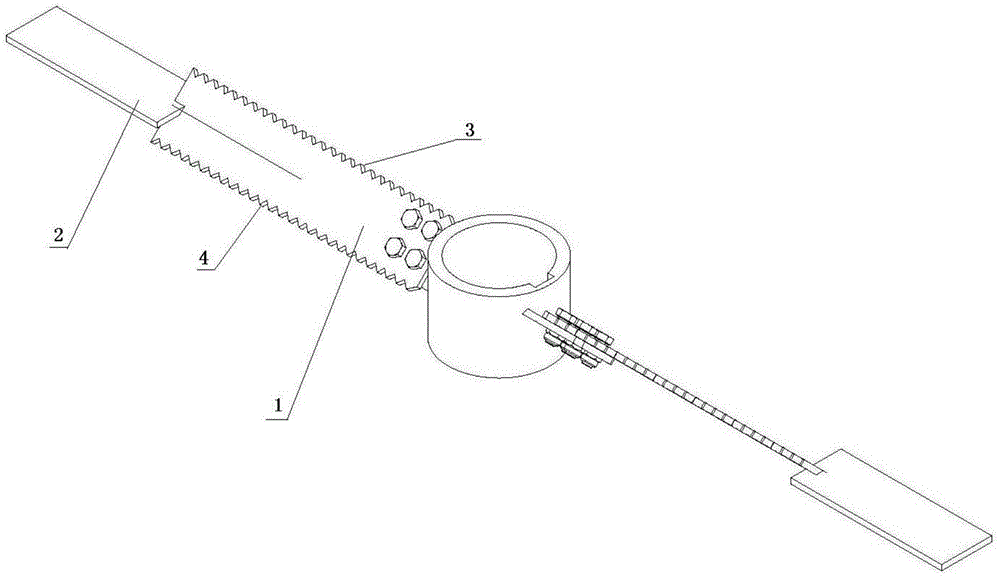

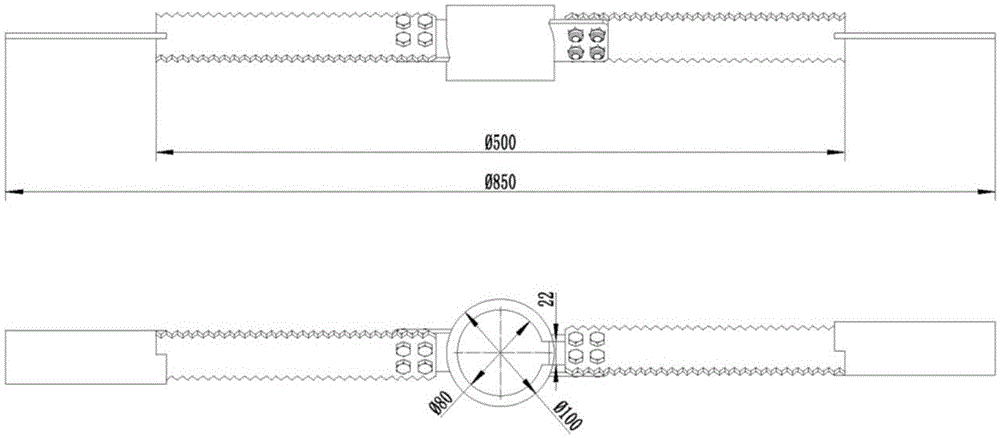

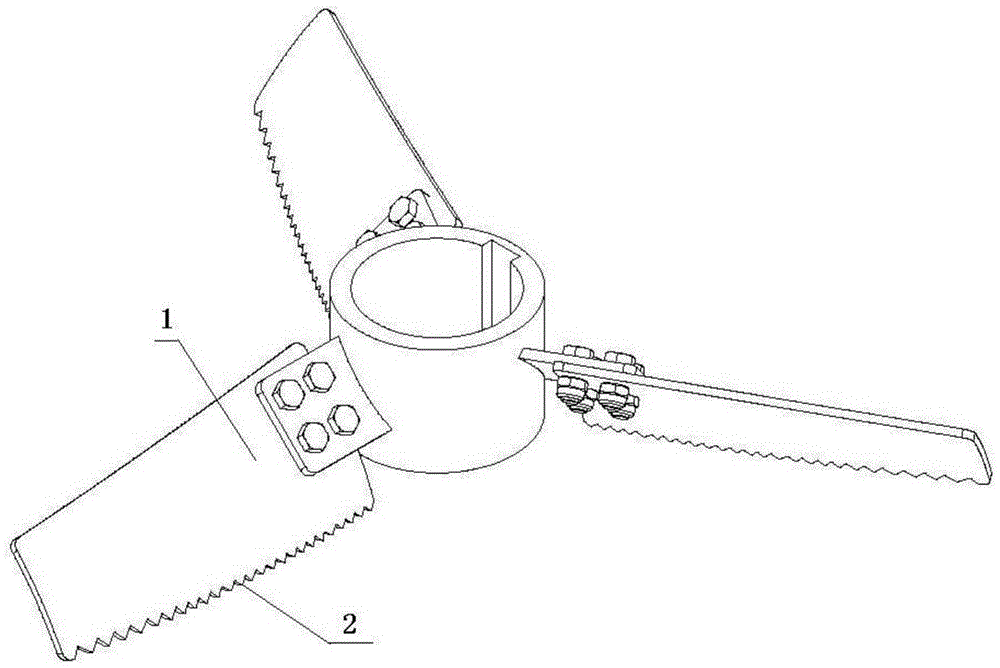

[0066] Supplied with double deck combination paddles. The upper mixing paddle is a variable cross-section two-blade oblique paddle, the front and rear edges of the main paddle are serrated, the sawtooth height is 15mm, and the included angle between the small paddle and the main paddle is 45°; Narrow-bladed airfoil blades, the height of the sawtooth on the rear edge of the blade is 15mm. Assemble the double-layer combined paddle with the 1800L concentrated tank and fix it on the stirring shaft. The ratio of the diameter of the paddle to the inner diameter of the tank is 0.4:1. see Figure 5 , Figure 5 It is a schematic structural diagram of the gelatin concentration tank provided in Example 1 of the present invention, wherein, 1 is a motor and a reducer, 2 is a coupling, 3 is a reducer frame, 4 is a double-end mechanical seal, and 5 is a reducer Machine base, 6 is a stirring shaft, 7 is a variable cross-section two-blade oblique paddle, and 8 is a three-narrow-blade airfoi...

Embodiment 2

[0074] Supplied with double deck combination paddles. The upper mixing paddle is a variable cross-section two-bladed oblique paddle, the front and rear edges of the main paddle are serrated, the sawtooth height is 14.5mm, and the included angle between the small paddle and the main paddle is 44.5°; the bottom paddle is Three narrow-blade airfoil blades, the sawtooth height of the rear edge of the blade is 14.5mm. Assemble the double-layer combined paddles with the 1500L concentrated tank and fix them on the stirring shaft. The ratio of the length of the paddle to the inner diameter of the tank is 0.3:1. see Figure 5 , Figure 5 It is a schematic structural diagram of the gelatin concentration tank provided in Example 1 of the present invention, wherein, 1 is a motor and a reducer, 2 is a coupling, 3 is a reducer frame, 4 is a double-end mechanical seal, and 5 is a reducer Machine base, 6 is a stirring shaft, 7 is a variable cross-section two-blade oblique paddle, and 8 is ...

Embodiment 3

[0082] Supplied with double deck combination paddles. The upper mixing paddle is a variable cross-section two-blade oblique paddle, the front and rear edges of the main paddle are serrated, the sawtooth height is 15.5mm, and the included angle between the small paddle and the main paddle is 45.5°; the bottom paddle is Three narrow-blade airfoil blades, the sawtooth height of the rear edge of the blade is 15.5mm. Assemble the double-layer combination paddle with the 2000L concentrated tank and fix it on the stirring shaft. The ratio of the length of the paddle to the inner diameter of the tank is 0.5:1. see Figure 5 , Figure 5 It is a schematic structural diagram of the gelatin concentration tank provided in Example 1 of the present invention, wherein, 1 is a motor and a reducer, 2 is a coupling, 3 is a reducer frame, 4 is a double-end mechanical seal, and 5 is a reducer Machine base, 6 is a stirring shaft, 7 is a variable cross-section two-blade oblique paddle, and 8 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com