Pressurized rotary screw powder feeder

A feeder and powder technology, which is applied in the field of pressurized rotary screw powder feeder, can solve the problems of dragging enterprises to meet environmental protection standards, hindering the improvement of production efficiency of enterprises, and difficult to realize the adjustment of conveying capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

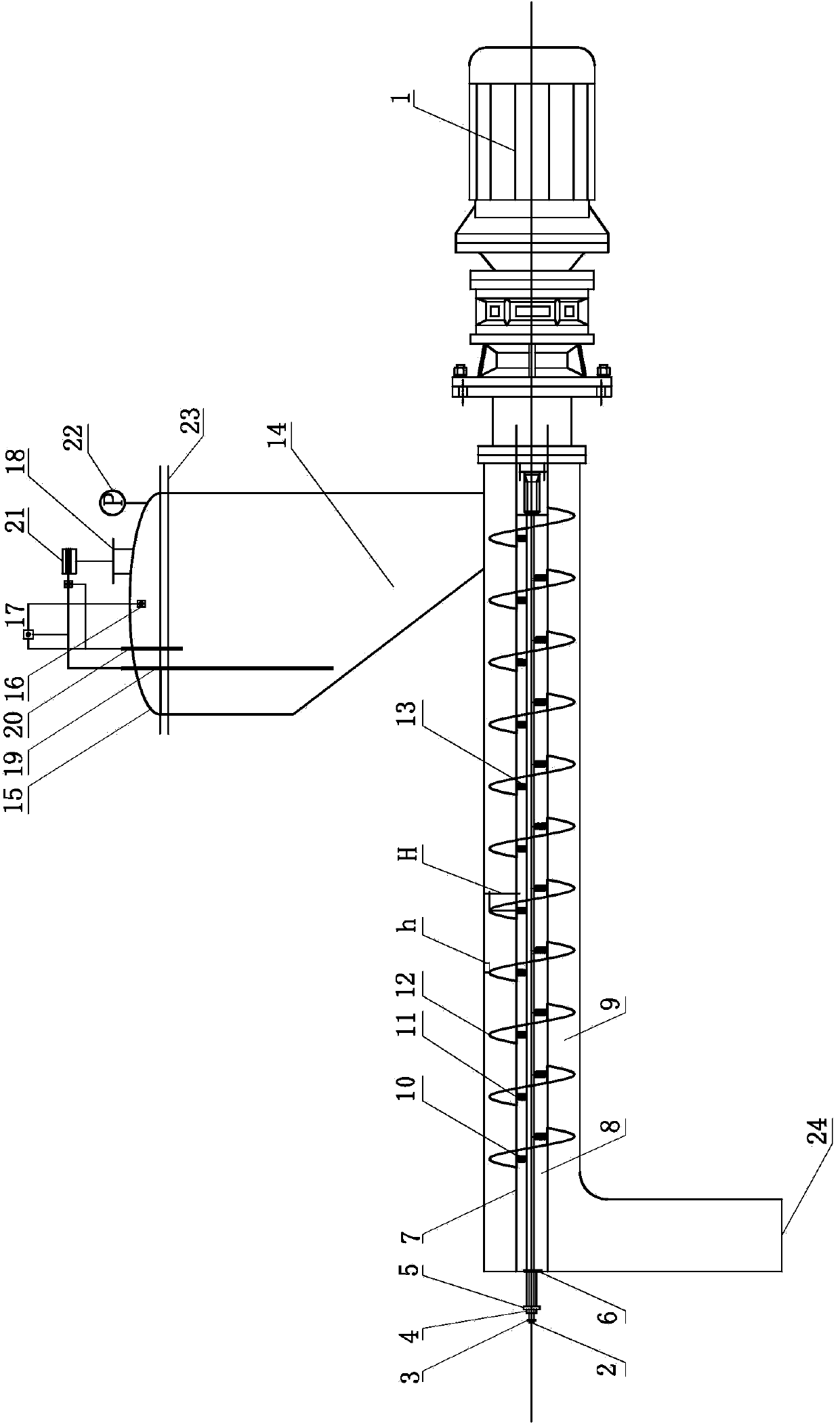

[0075] Embodiment 1: pressurized rotary screw powder feeder of the present invention

[0076] The pressurized rotary screw powder feeder is composed of a speed regulating motor, a powder bin and a screw powder feeder.

[0077] The powder silo includes a powder silo body 14, a powder silo cover 15 and a sealing flange 23; a pneumatic stirring mechanism 16, a stirring air source 17, a powder silo inlet 18, Low material level probe 19, high material level probe 20, automatic filling control mechanism 21 and pressure gauge 22;

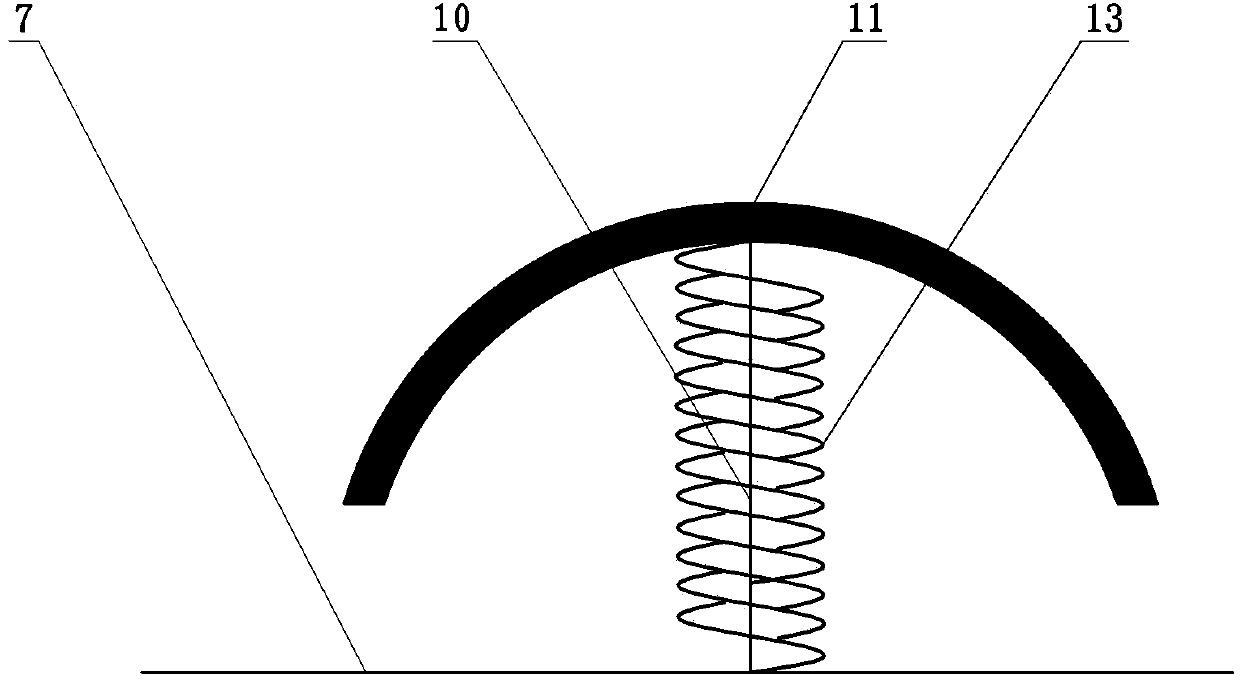

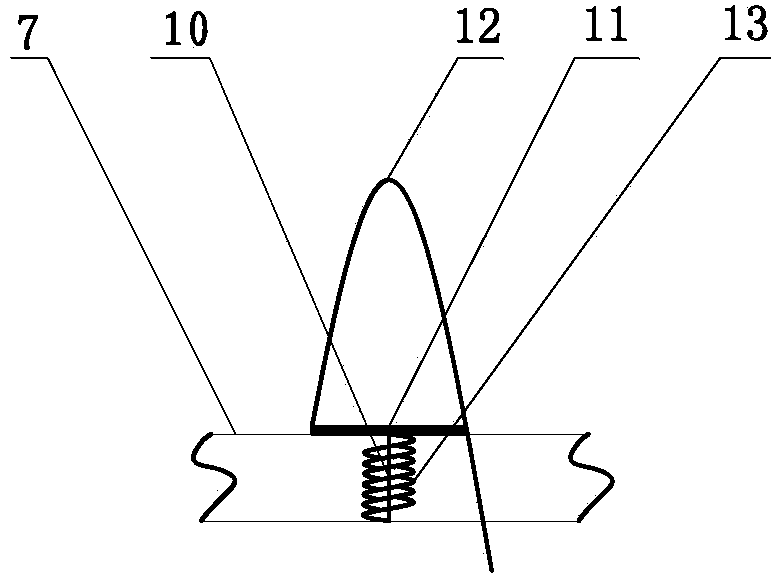

[0078] The screw powder feeder includes a speed regulating motor 1, a stepped lifting mechanism 2, a stepped lifting mechanism adjusting switch 3, an integral lifting mechanism 4, an integral lifting mechanism adjusting switch 5, a connecting bearing with a sealing ring 6, a rotating Screw 7, screw feeder hollow cavity 8, screw feeder feeding cavity 9, positioning rod 10, arc-shaped spring piece 11, sail-type blade 12 and lifting spring 13;

[0079] When...

Embodiment 2

[0087] Embodiment 2: pressurized rotary screw powder feeder of the present invention

[0088] Use the same pressurized rotary screw powder feeder as in Example 1 to transport pulverized coal and limestone powder mixture under the conditions of the following raw material parameters and feeder operating parameters:

[0089] Table 3: Raw material parameters

[0090]

[0091] Table 4: Feeder operating parameters

[0092]

[0093] The material is qualified pulverized coal with a particle size of ≥200 mesh and ≥80% by weight, and limestone powder with a particle size of ≤100 mesh and ≥10% by weight. Mix them evenly and fill them in the powder bin of the feeder. The mixing mechanism fills the powder bin with carbon dioxide, the overall lifting mechanism adjusts the distance between the top of the sail blade and the inner wall of the feeding chamber h=25.00mm, the speed of the speed regulating motor is adjusted to 40.0r / min, and the powder flow at the outlet of the rotary screw...

Embodiment 3

[0094] Embodiment 3: Pressurized rotary screw powder feeder of the present invention: pulverized coal mixed with coal, limestone powder, carbon dioxide.

[0095] Use the same pressurized rotary screw powder feeder as in Example 1 to transport pulverized coal mixed coal and limestone powder mixture under the conditions of the following raw material parameters and feeder operating parameters:

[0096] Table 5: Raw material parameters

[0097]

[0098] Table 6: Feeder parameters

[0099]

[0100] The particle size is ≥150 mesh, ≥80% by weight qualified pulverized coal mixed with coal and the particle size is ≤100 mesh, ≥10% by weight limestone powder is mixed and filled in the feeder's own powder bin, sealed powder bin, and the powder is fed by the pneumatic stirring mechanism The warehouse is filled with nitrogen with a small flow rate, the overall lifting mechanism adjusts the distance between the top of the sail blade and the inner wall of the feeding chamber h=60.00mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com