Tonnage-load bag filling equipment

A kind of equipment and filling technology, applied in the direction of packaging, transportation and packaging, containers, etc., can solve the problems of feeding pipe blockage, affecting weighing accuracy, etc., achieve the effect of accurate measurement and enhanced arch breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

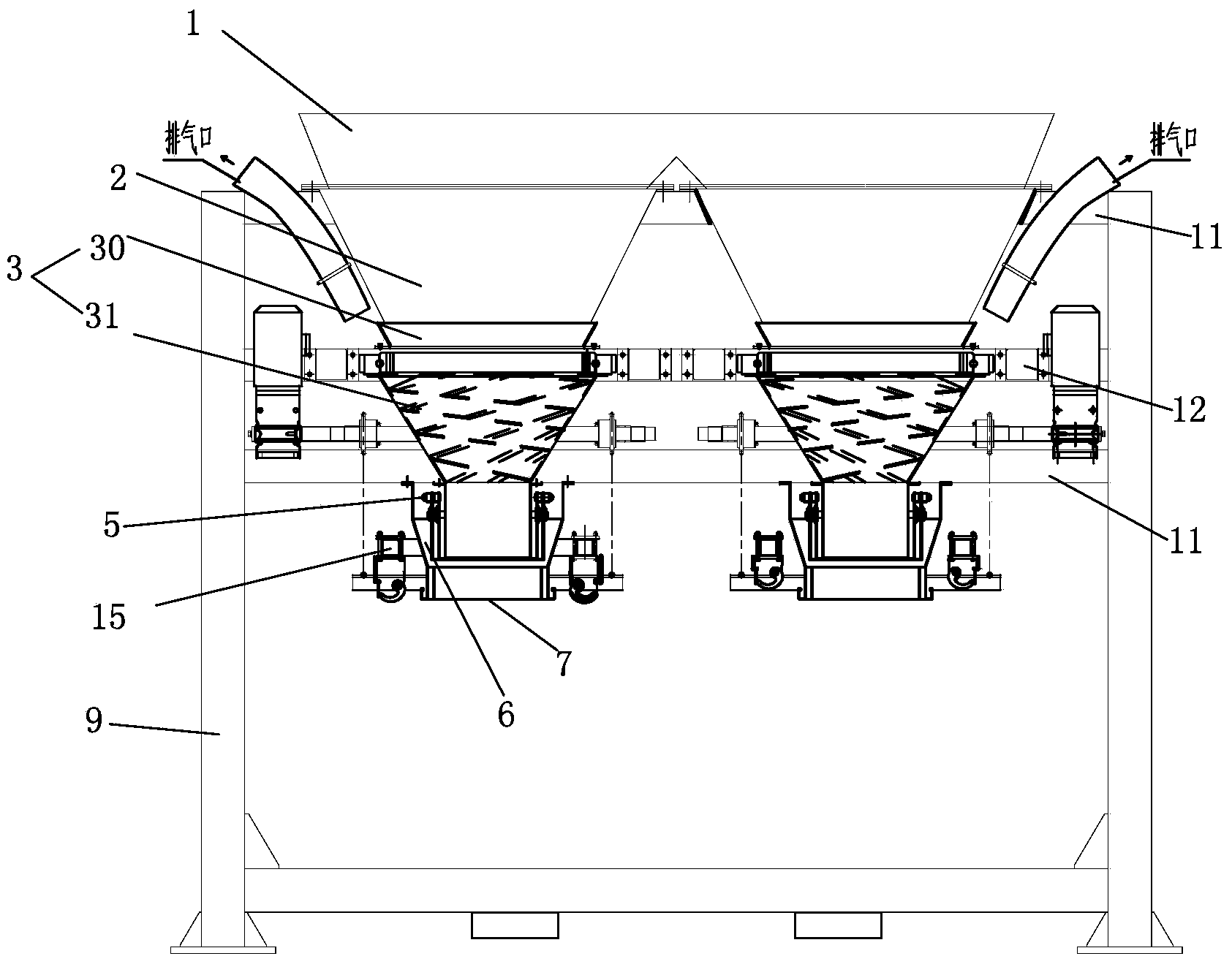

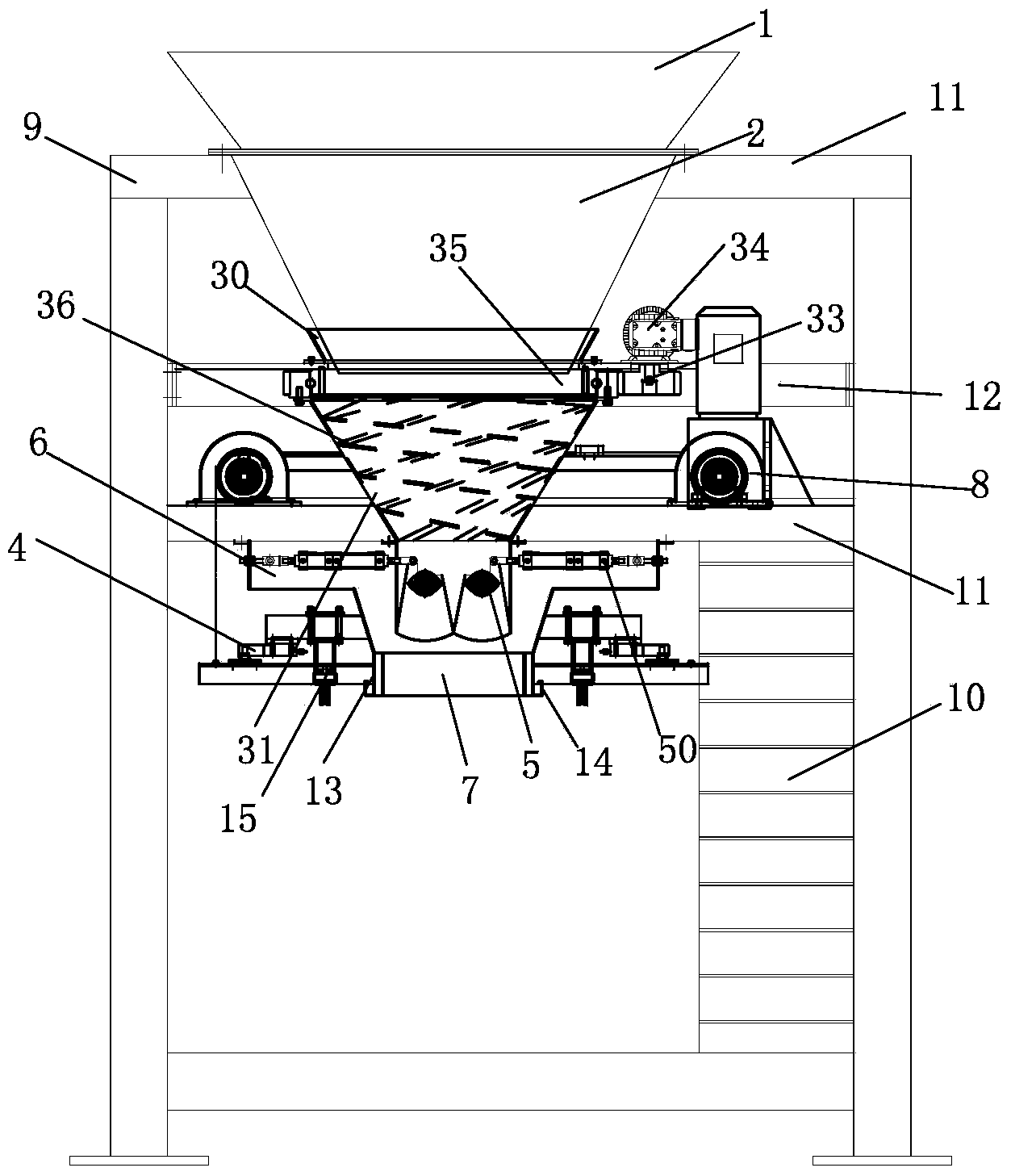

[0022] This embodiment is described by taking two feed bins as an example. like figure 1 and figure 2 As shown, the ton-loading and packaging equipment in the present invention includes a frame assembly 9, two side-by-side bins 2 installed on the frame assembly 9, a sensor assembly 4, a gate assembly 5, and a protective cover tube device 6. The feeding pipe 7 (also known as the feeding pipe) used to seal and connect the gate assembly 5 and the additional rotating silo 3 below the silo 2. Wherein the number of silos 2 can be one or more than two, and the specific number can be set according to the requirements of the port.

[0023] like figure 1 and figure 2 As shown, the frame assembly 9 is composed of a plurality of H-shaped steel materials or I-shaped steel materials welded to each other, and two upper and lower parallel fixed support frames 11 are formed by steel welding inside the frame assembly 9, and the support frame 11 located above Two circular hoops for fixing...

Embodiment 2

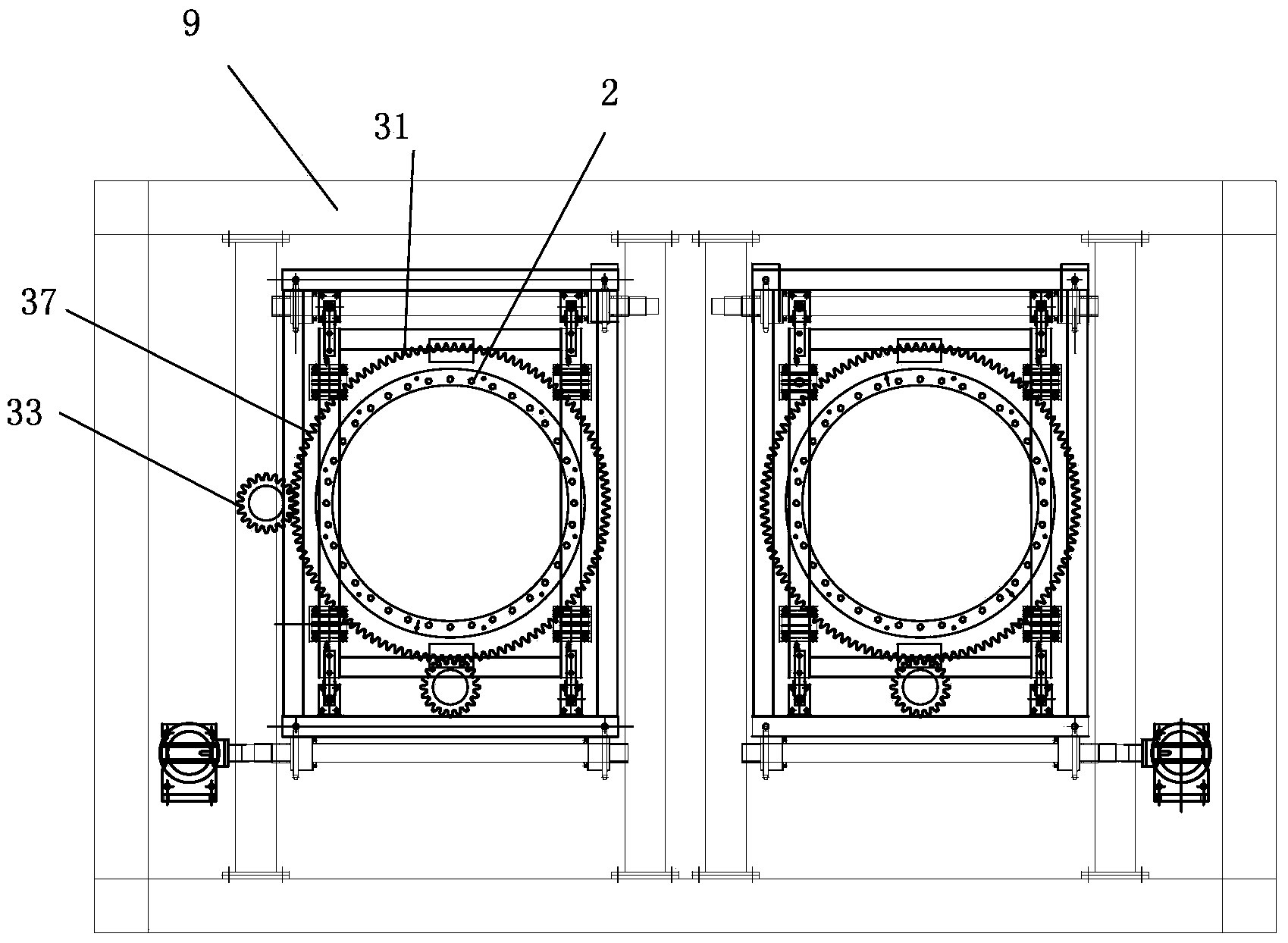

[0033] The ton packing equipment in this embodiment is basically similar to the first embodiment above, the difference is that the rotating bin 3 in this practical embodiment does not include a turntable 35, and directly connects the conical rotating bin body 31 with the conical The bin body 30 is sealed and connected and can rotate relatively, and an external gear 37 is processed on the outer wall of the conical rotating bin body 31, such as image 3 As shown, that is, the conical rotating bin body 31 is directly engaged with the driving gear 33 and is driven by the driving motor 33 .

Embodiment 3

[0035] The ton-loading packaging equipment in this embodiment is basically similar to the first embodiment above, the difference is that the rotating bin 3 in this practical embodiment includes a conical rotating bin body 31, such as Figure 4 As shown, the conical rotating silo body 31 is directly sleeved on the lower bottom of the silo 2, is sealed and connected with the lower bottom of the silo 2, and can be rotated relative to the lower end of the conical rotating silo body 31. The feed pipe 38 is directly fixed on the outer wall of the feed pipe 38 and can be engaged with the rotating disk 35 of the drive gear 33 . And the gate assembly 5 and the feeding pipe 7 in the above-mentioned embodiment are then used as sleeve pipes, directly sleeved outside the feeding pipe 38, are sealed with the feeding pipe 38, and can be relatively rotated. A scraper 36 is also provided on the inner wall of the feeding pipe 38 .

[0036] To sum up, the setting of the rotating silo between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com