Patents

Literature

94 results about "Pack filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

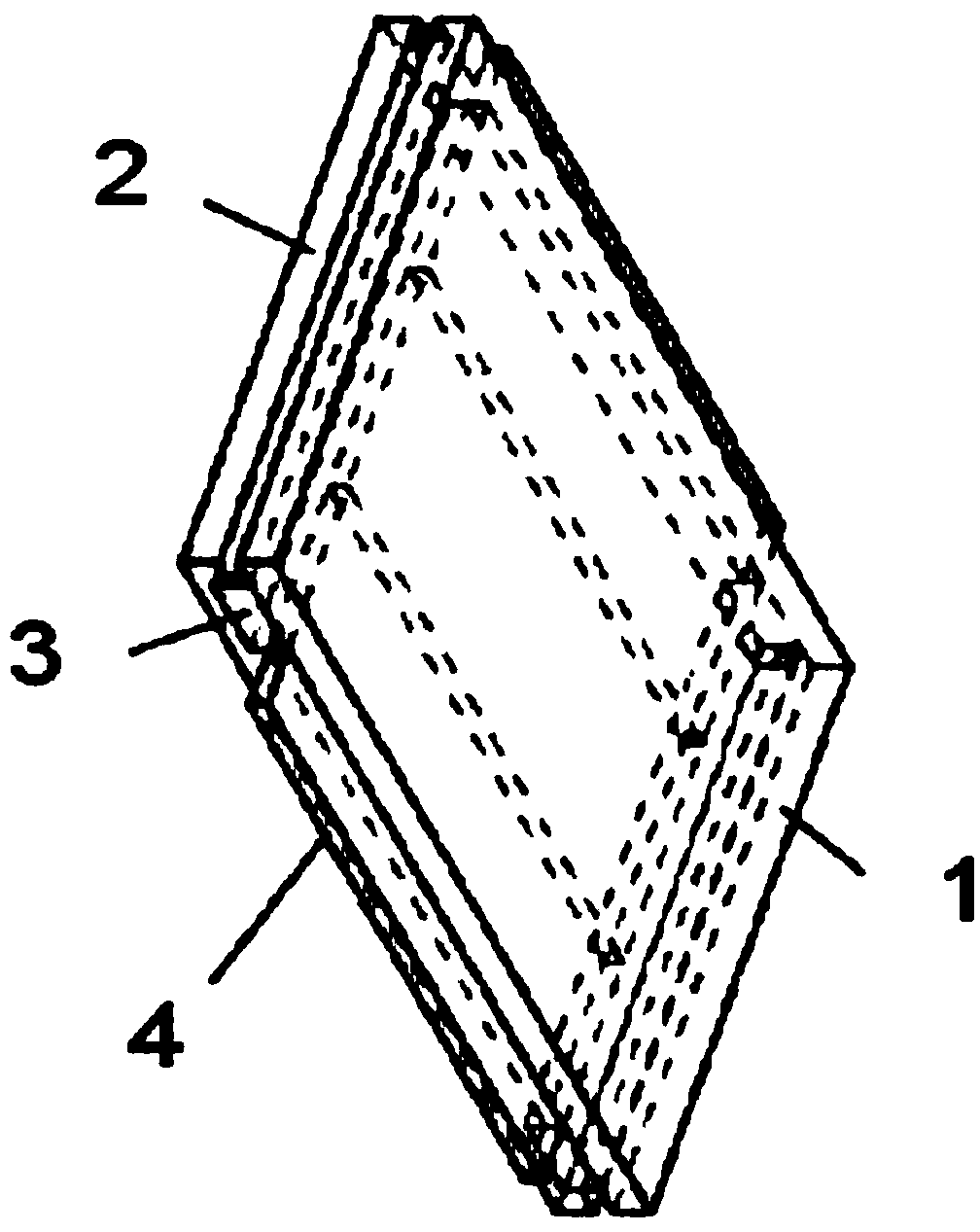

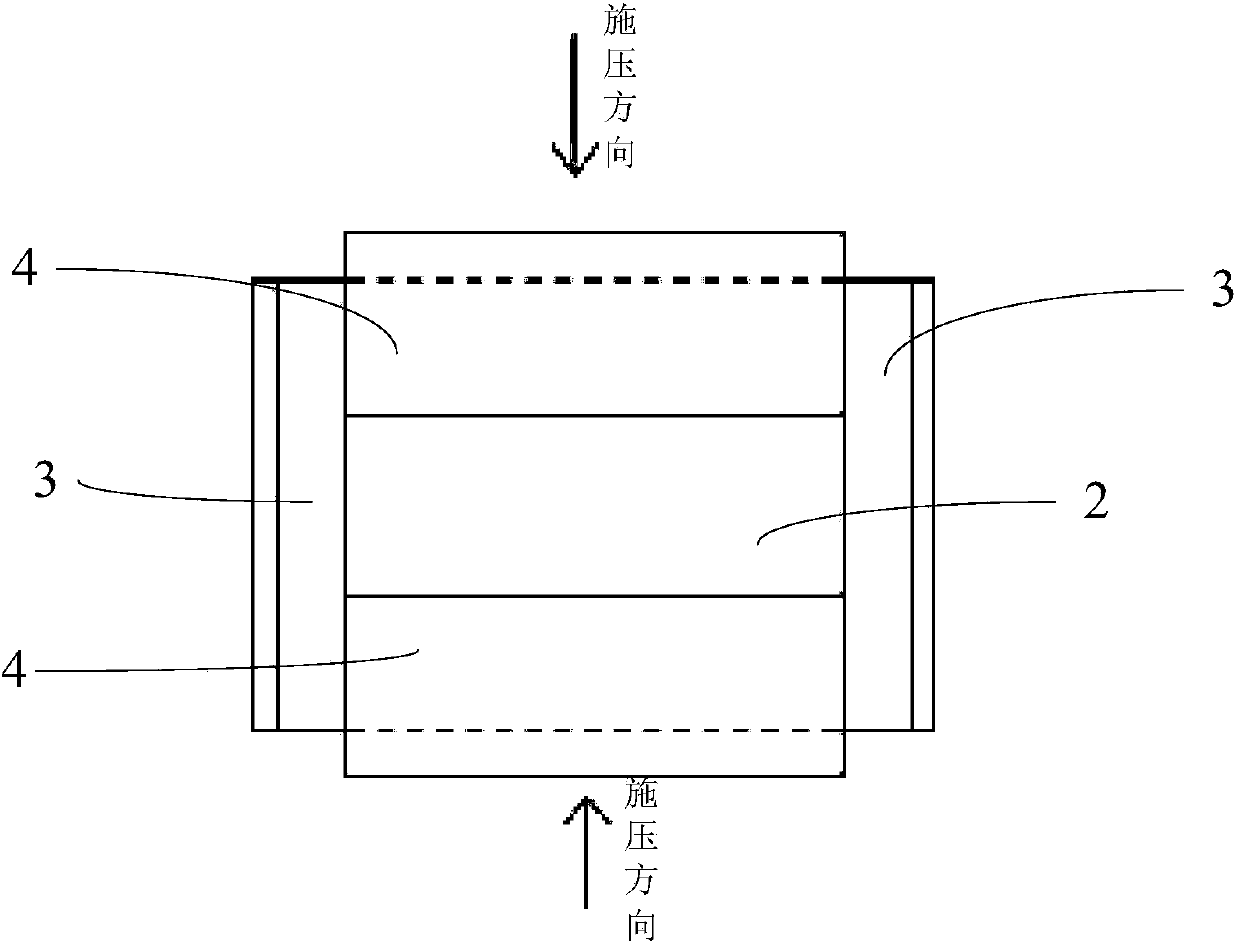

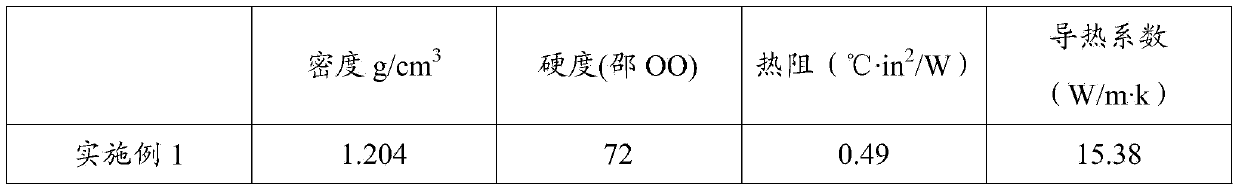

Oriented flexible heat conduction material as well as forming technology and application thereof

InactiveCN103740110AImprove thermal conductivityGood flexibilitySemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringPliability

The invention provides an oriented flexible heat conduction material. Main components of the oriented flexible heat conduction material are silicon rubber and anisotropism heat conduction packing. A plurality of heat conduction paths which are parallel to each other and continuous are formed in the oriented flexible heat conduction material by linearly and continuously arranging the anisotropism heat conduction packing filled in the silicon rubber in heat conduction path directions. The oriented flexible heat conduction material has good heat conduction property in a particular direction and good flexibility, can form good contact with an interface, is low in interface resistance and can be used for improving a heat dissipation effect very well. The embodiment of the invention also provides a forming technology and an application of the oriented flexible heat conduction material.

Owner:HUAWEI TECH CO LTD +2

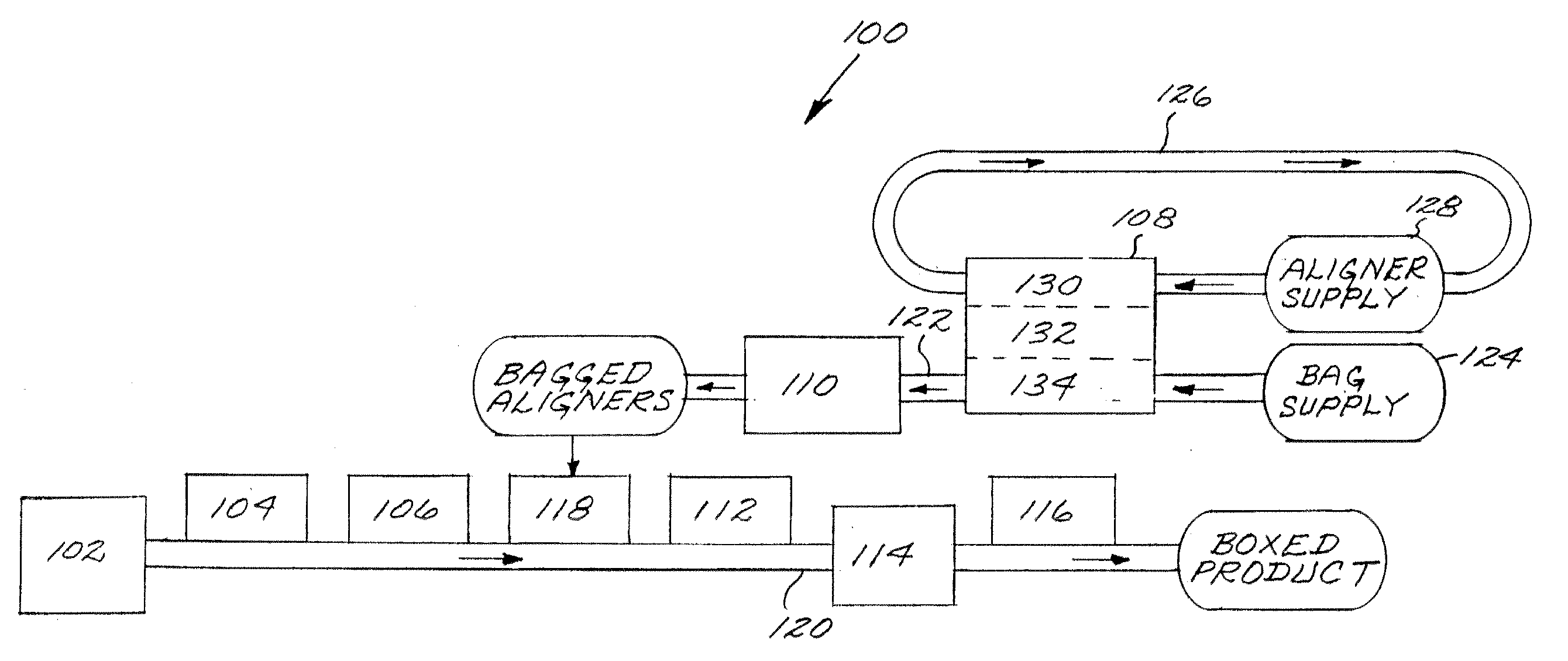

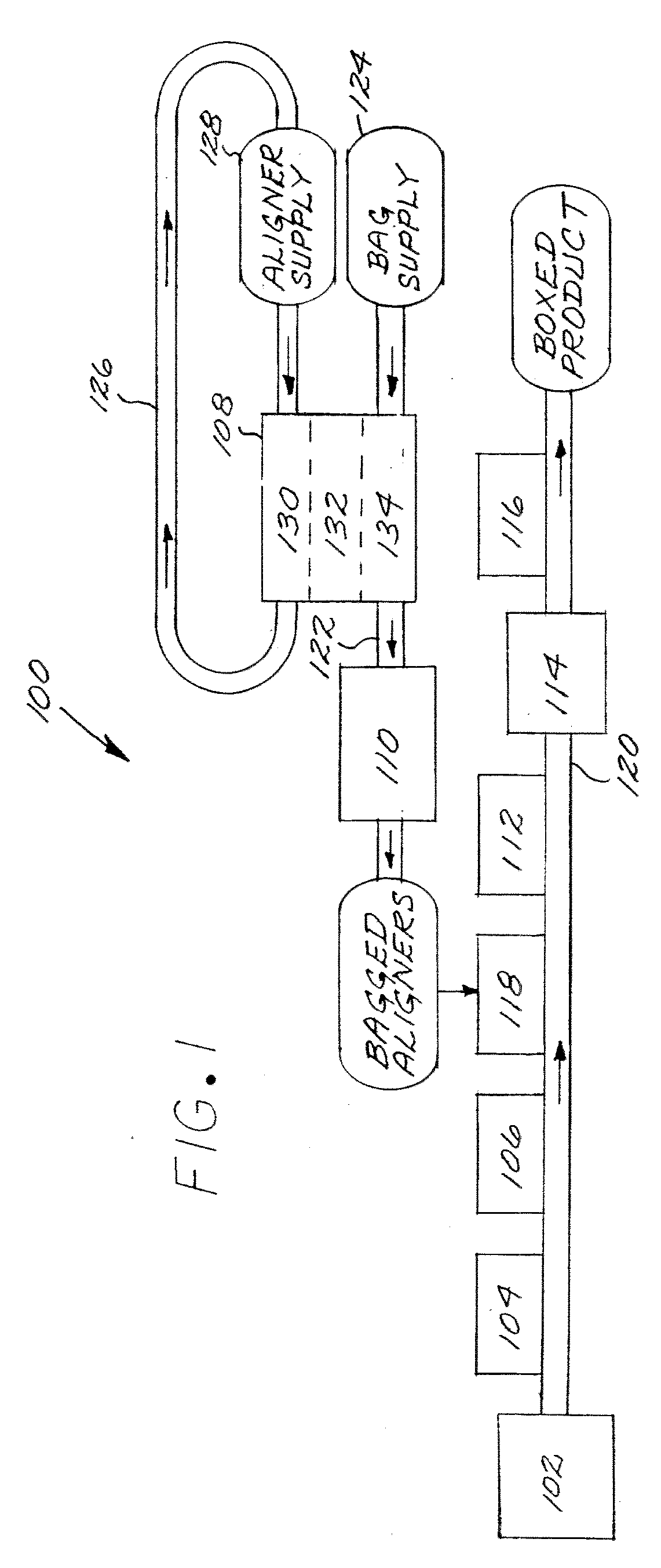

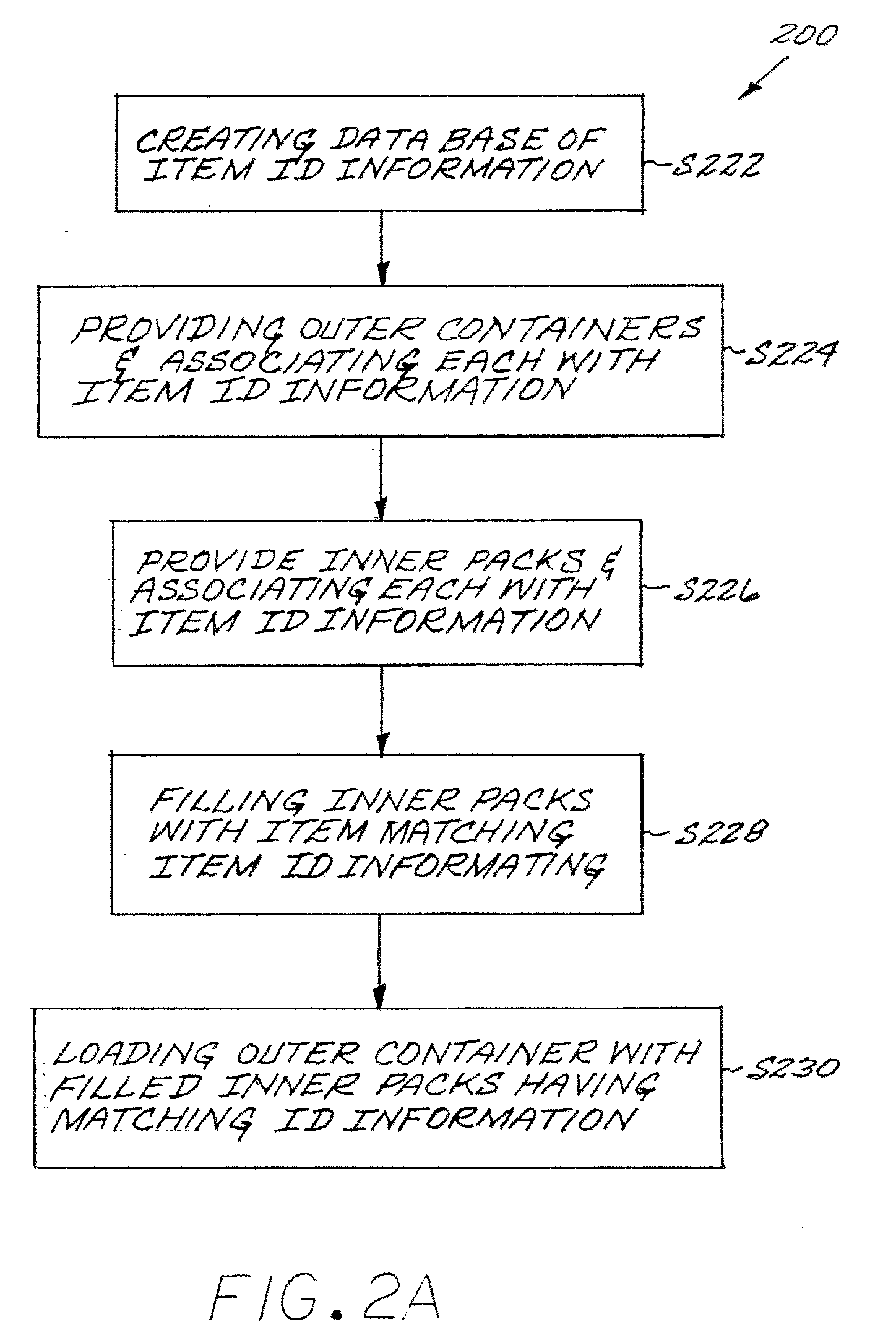

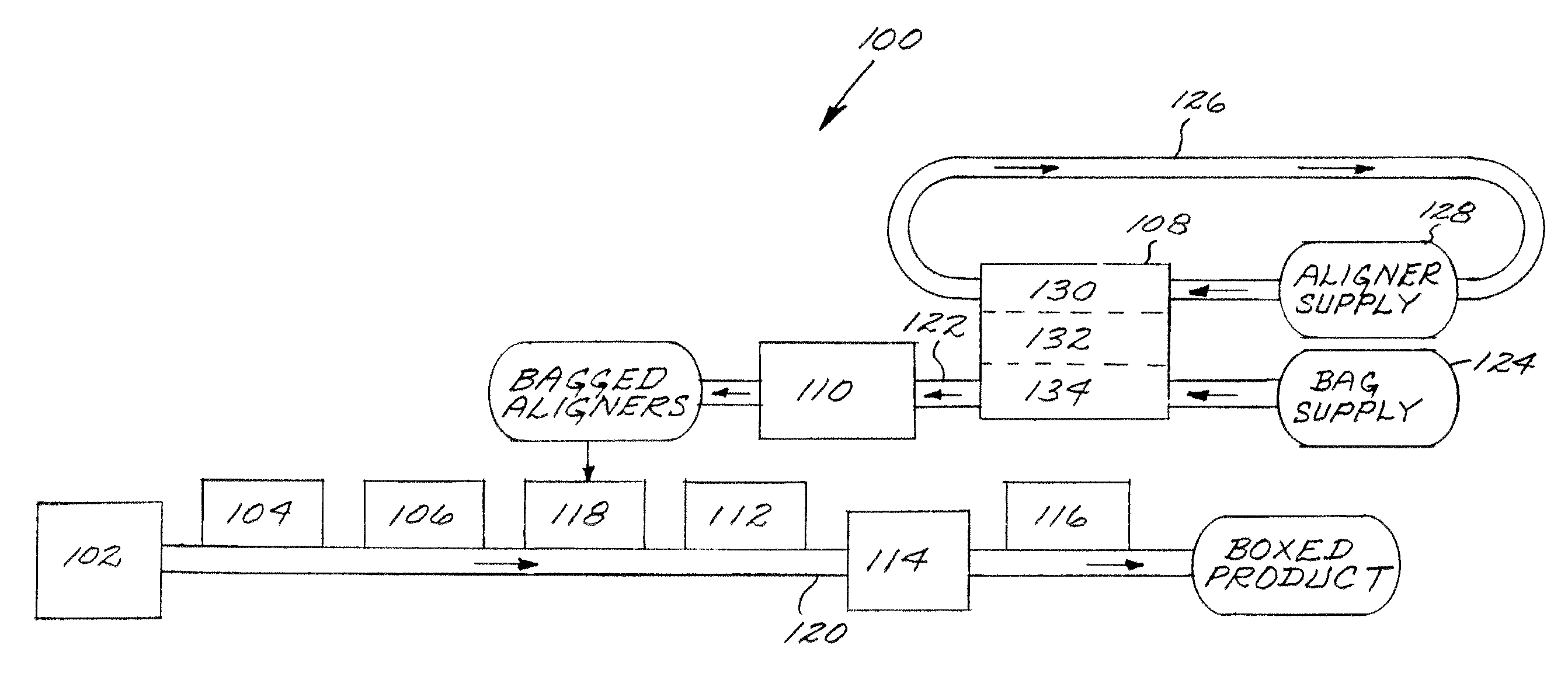

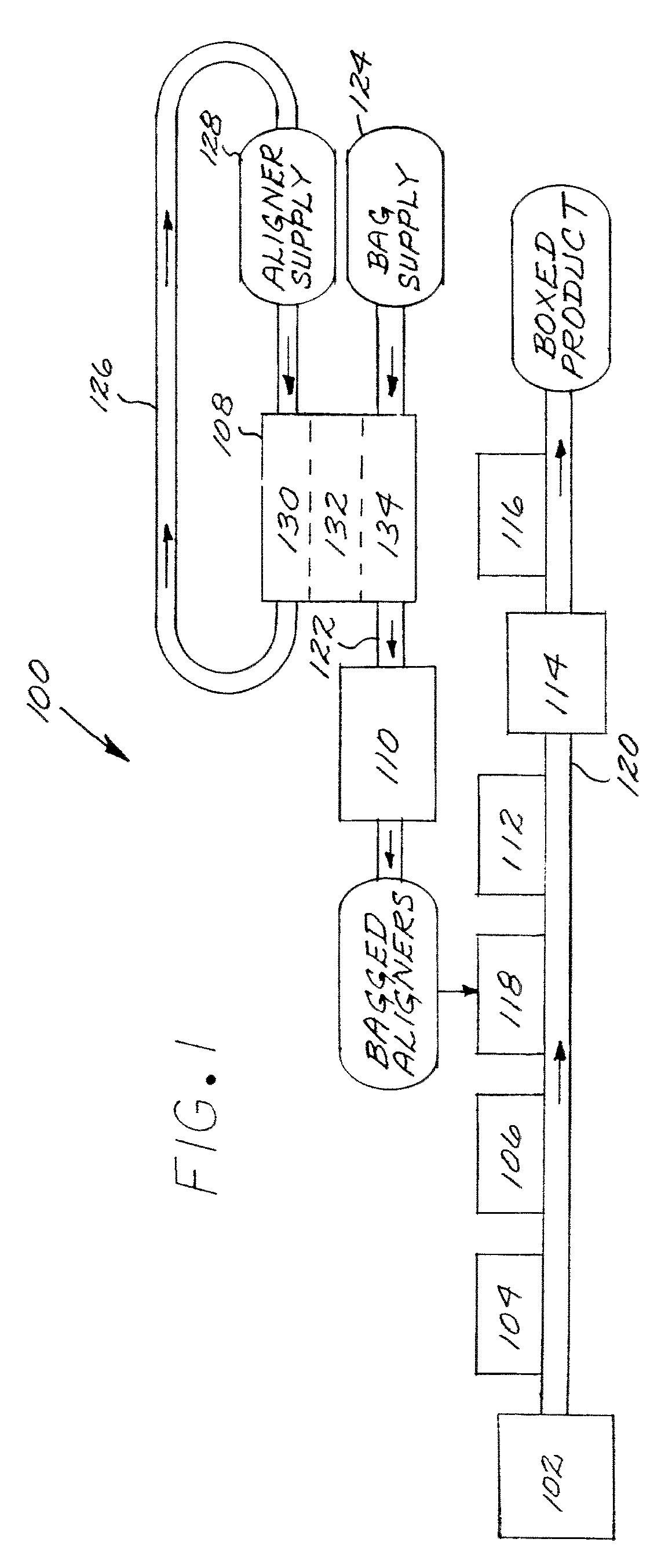

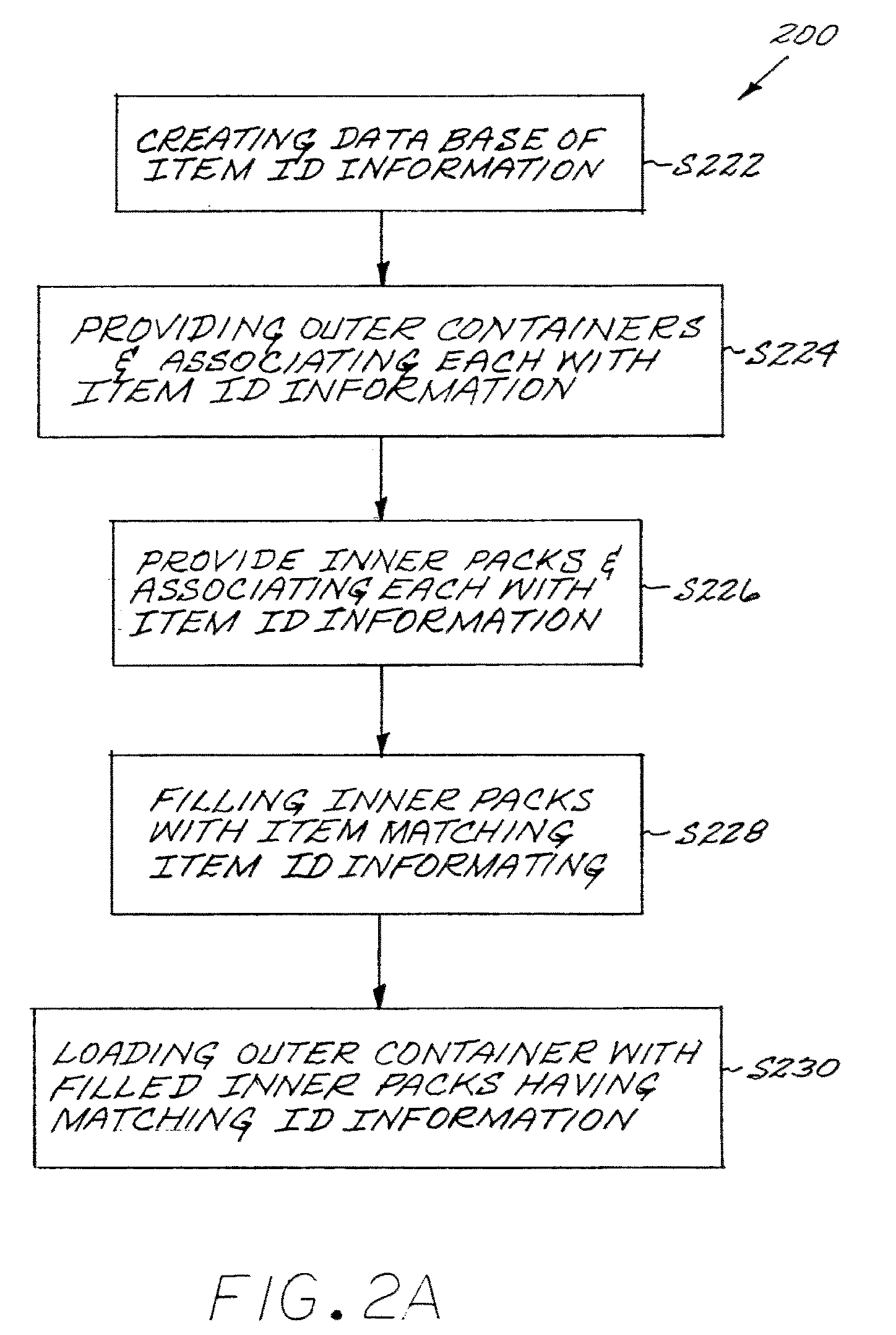

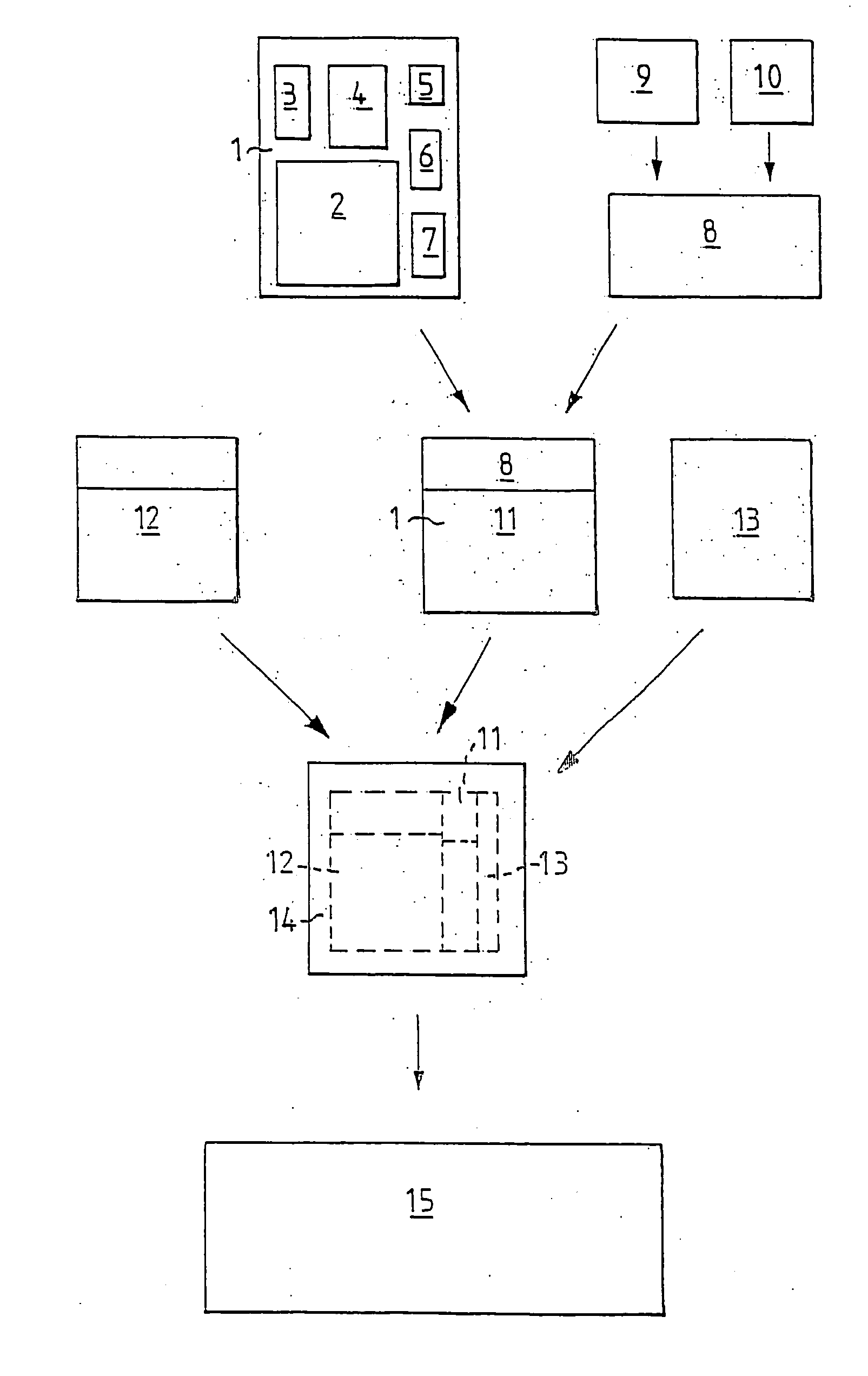

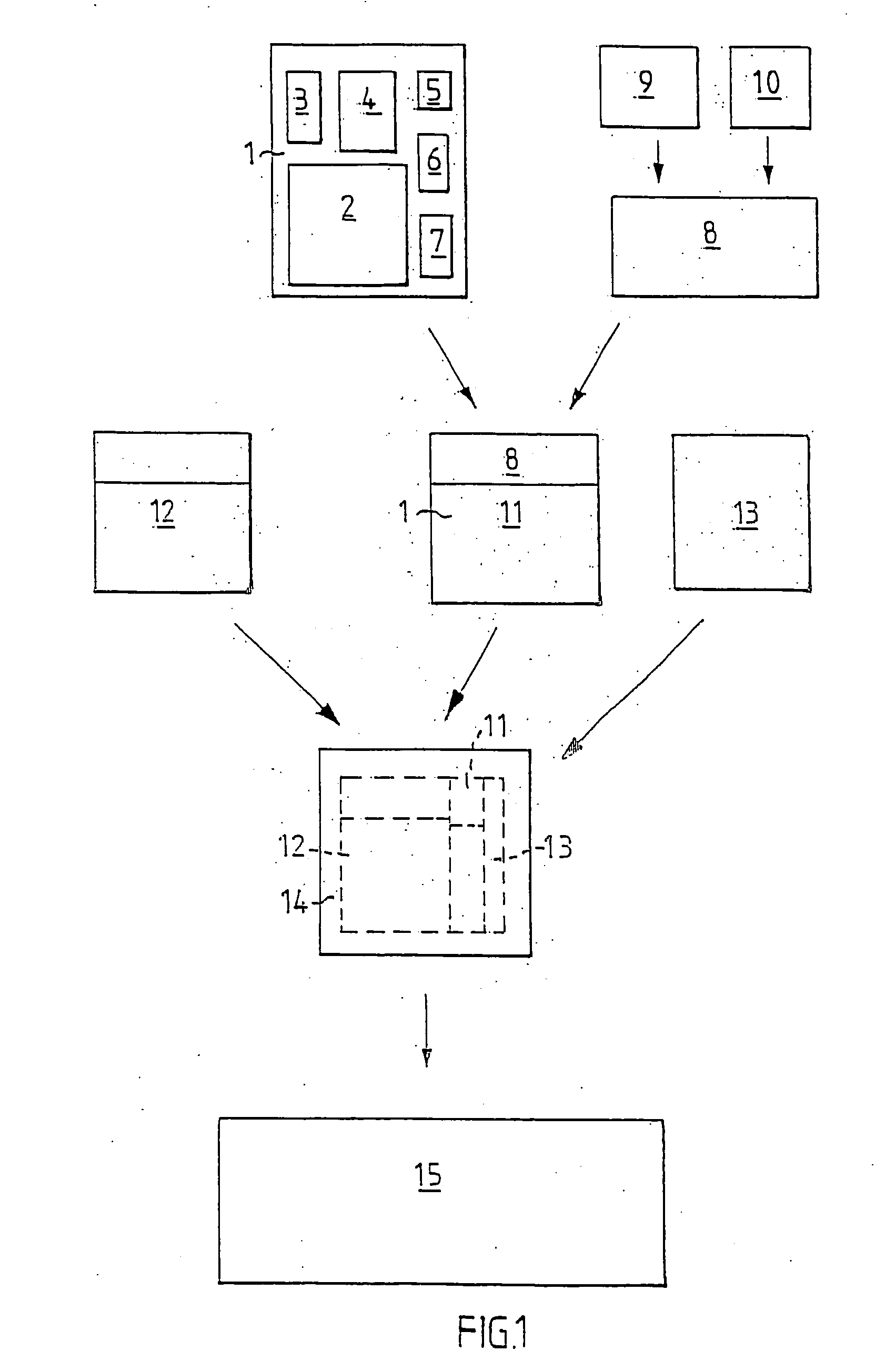

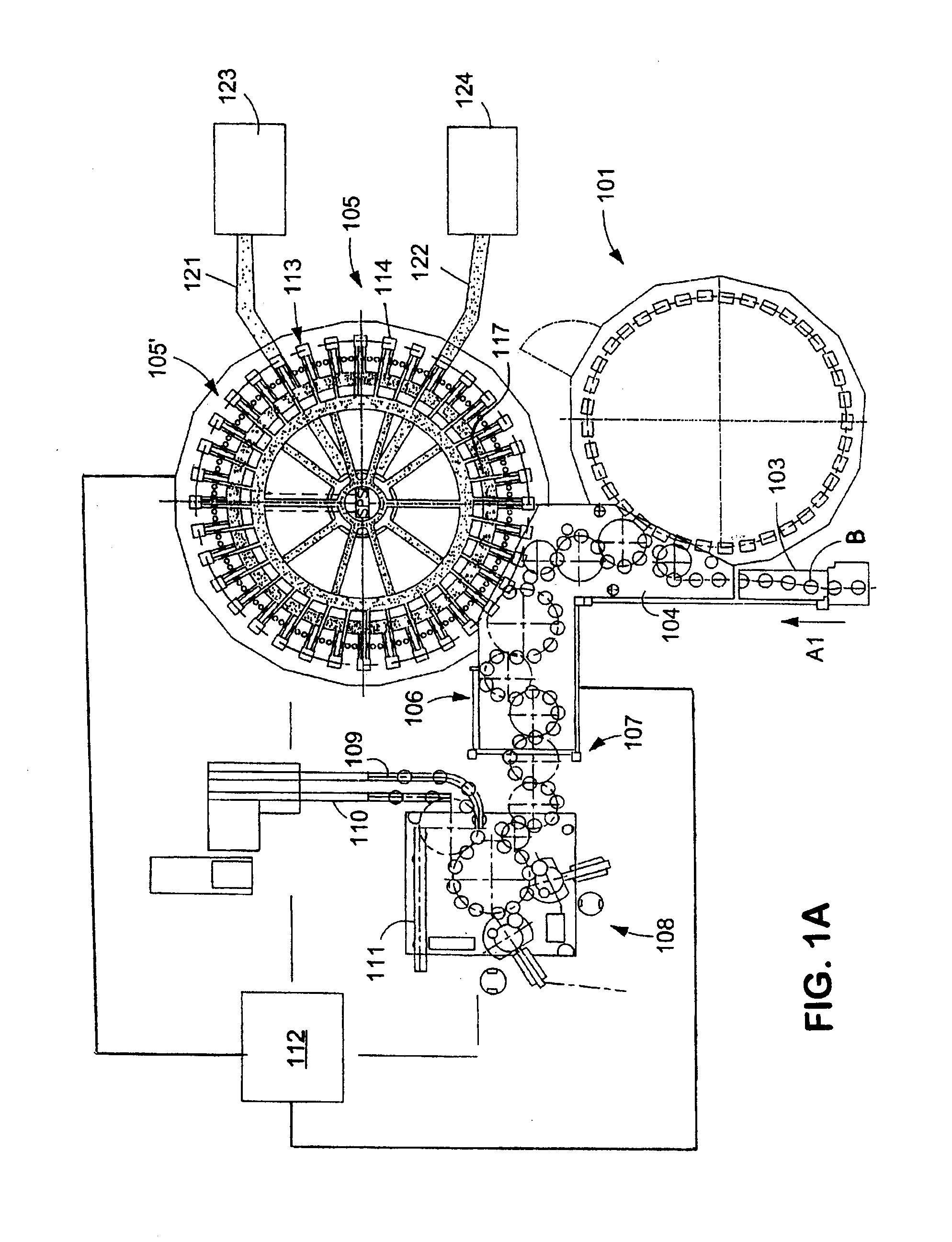

System and method for packaging of mass-fabricated custom items

ActiveUS20080121537A1Container/bottle contructionPackaging automatic controlEngineeringIdentification device

A system for packaging mass-customized items includes a computer system including a database containing item identification information unique to each item; (2) outer container identification apparatus that applies the item identification information received from the database to each outer container in a plurality of outer containers; (3) inner pack identification apparatus that applies the item identification information received from the database to each inner pack in a plurality of inner packs; and (4) inner pack filling apparatus that fills each inner pack with a specific item matched to that inner pack by the item identification information received from the database. Each item is associated with its unique item identification information and is inserted into an inner pack with matching item identification information, and each outer container is presented for loading with one or more inner packs matched to that outer container by the item identification information received from the database.

Owner:ALIGN TECH

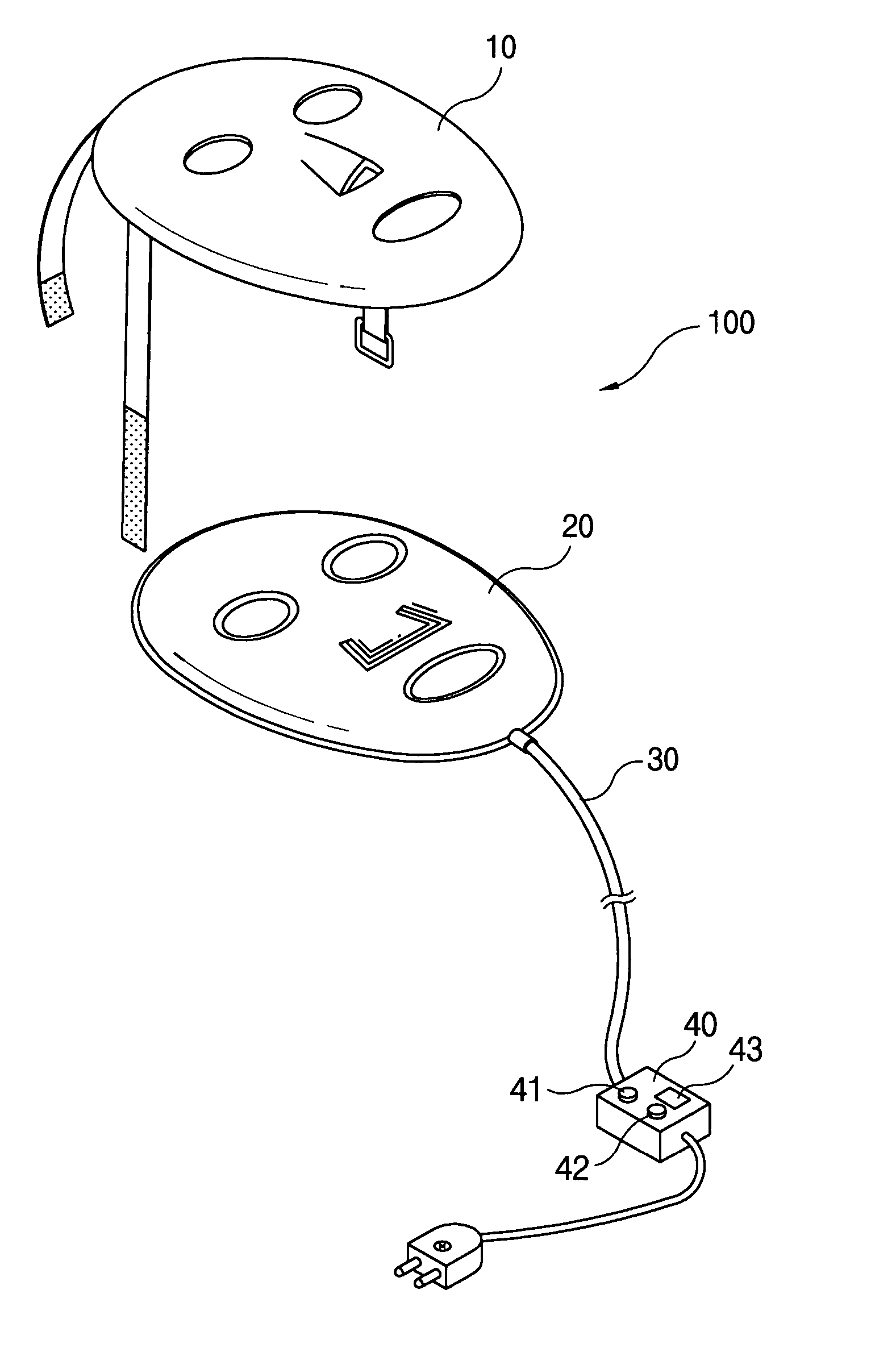

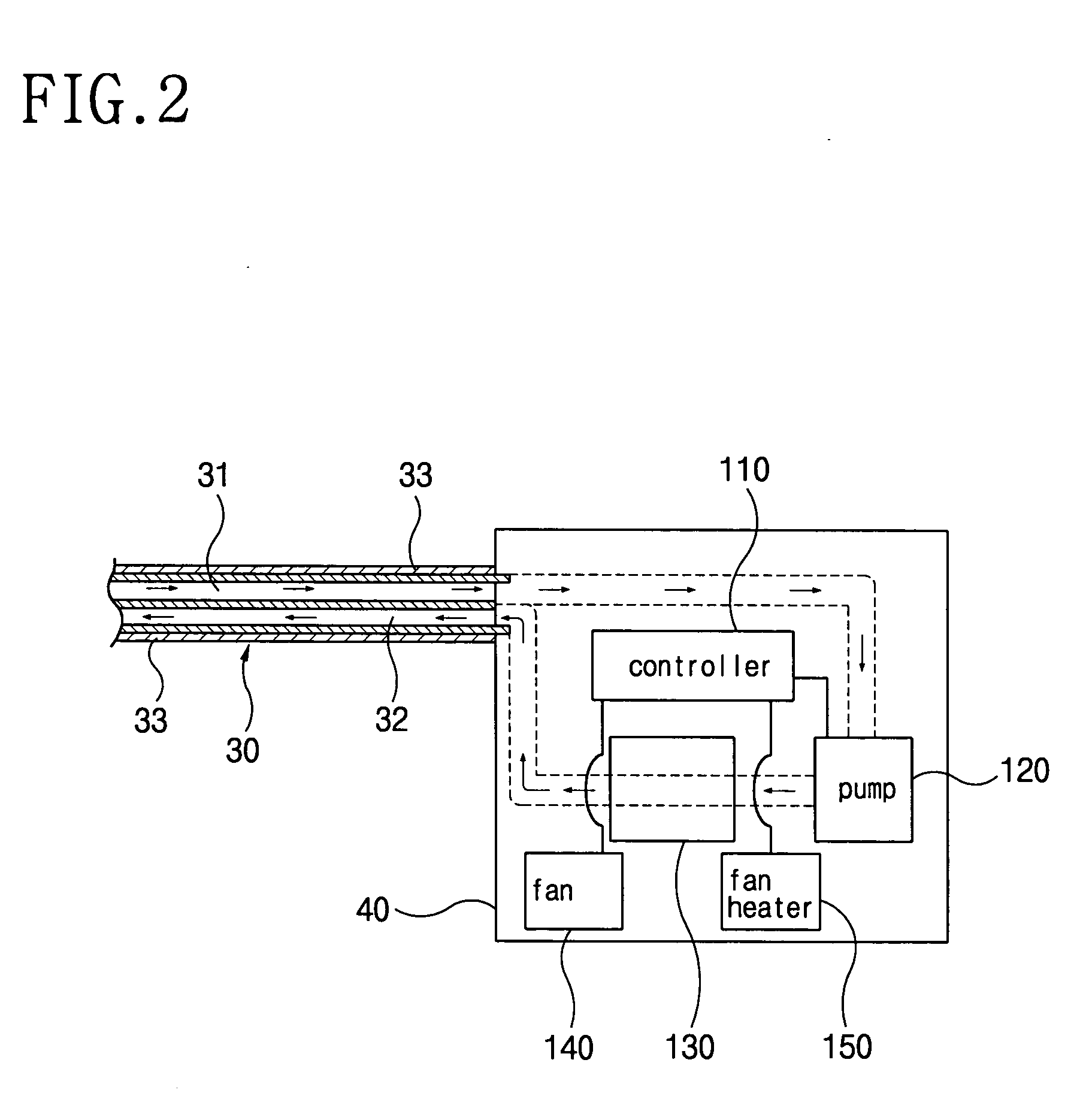

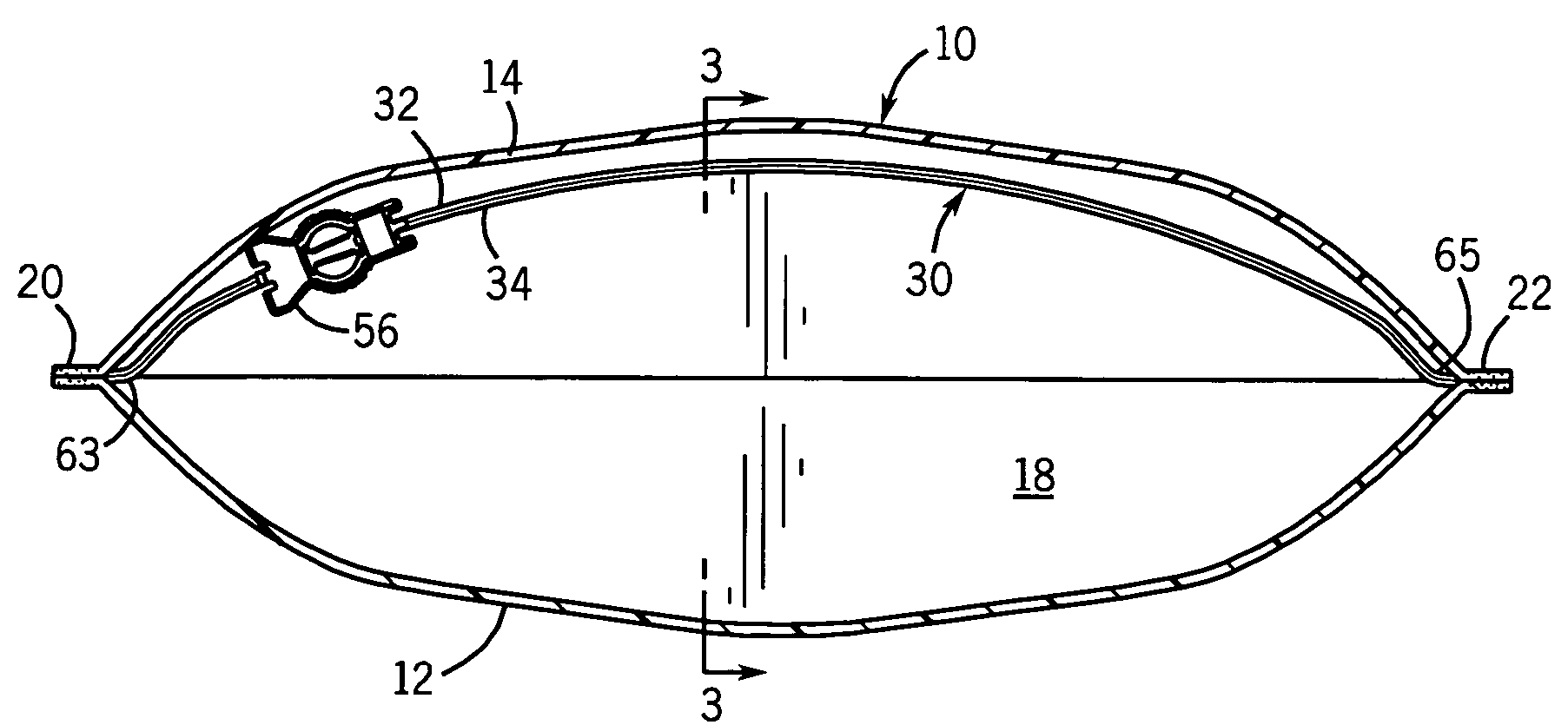

Beauty mask

InactiveUS20050131504A1To promote metabolismIncrease elasticityTherapeutic coolingTherapeutic heatingWrinkle skinEngineering

The present invention is directed to a beauty mask having a circulator using a thermoelectric element, more specifically the beauty mask in which a urethane pack filled with silicon oil is attached on inner surface of a face mask, a tube allowing the silicon oil cooled or heated by the thermoelectric element to flow in or out the pack is connected to the urethane pack, and the urethane pack is cooled or heated according to a temperature of the inflow silicon oil and provides cold and hot packing effect to the face, so that a metabolism of a face skin is facilitated, the resilience of the skin is improved, and wrinkle can be eliminated. By using of the beauty mask according to the present invention, an aging phenomenon of the skin can be suppressed, waste material stuck in a hypodermis of a facial skin can be discharged therefrom, and a blood circulation of the facial skin is smoothly achieved due to cold and hot packing effect

Owner:MG CARE

System and method for packaging of mass-fabricated custom items

ActiveUS7748199B2Packaging automatic controlIndividual articlesComputerized systemIdentification device

A system for packaging mass-customized items includes a computer system including a database containing item identification information unique to each item; (2) outer container identification apparatus that applies the item identification information received from the database to each outer container in a plurality of outer containers; (3) inner pack identification apparatus that applies the item identification information received from the database to each inner pack in a plurality of inner packs; and (4) inner pack filling apparatus that fills each inner pack with a specific item matched to that inner pack by the item identification information received from the database. Each item is associated with its unique item identification information and is inserted into an inner pack with matching item identification information, and each outer container is presented for loading with one or more inner packs matched to that outer container by the item identification information received from the database.

Owner:ALIGN TECH

Ballistic fire protection packaging system

Owner:THE BOEING CO

Method of packaging and sterilizing disposable articles for surgical operations and such a package

InactiveUS20060231443A1Dispensing apparatusDiagnosticsEthylene Oxide SterilizationBiomedical engineering

A method of packaging and sterilizing disposable articles for surgical operations, in which several surgical articles are packed in a first package that is packed in a transport package and thereafter transported to a plant for sterilizing with the aid of ethylene oxide, whereafter the first package is sterilized in this plant. A second package containing sterile packaged surgical articles of a type, that can not sustain sterilizing, or for other reasons should not be sterilized with ethylene oxide, is brought together with the first package before this package is packed into the transport package and before this package is transported to the sterilizing plant, the second package being impermeable to ethylene oxide. A transport package used in the method and a package for sterile packaged articles, which can not sustain sterilizing or should not be sterilized with ethylene oxide is also disclosed.

Owner:MOLNLYCKE HEALTH CARE AB

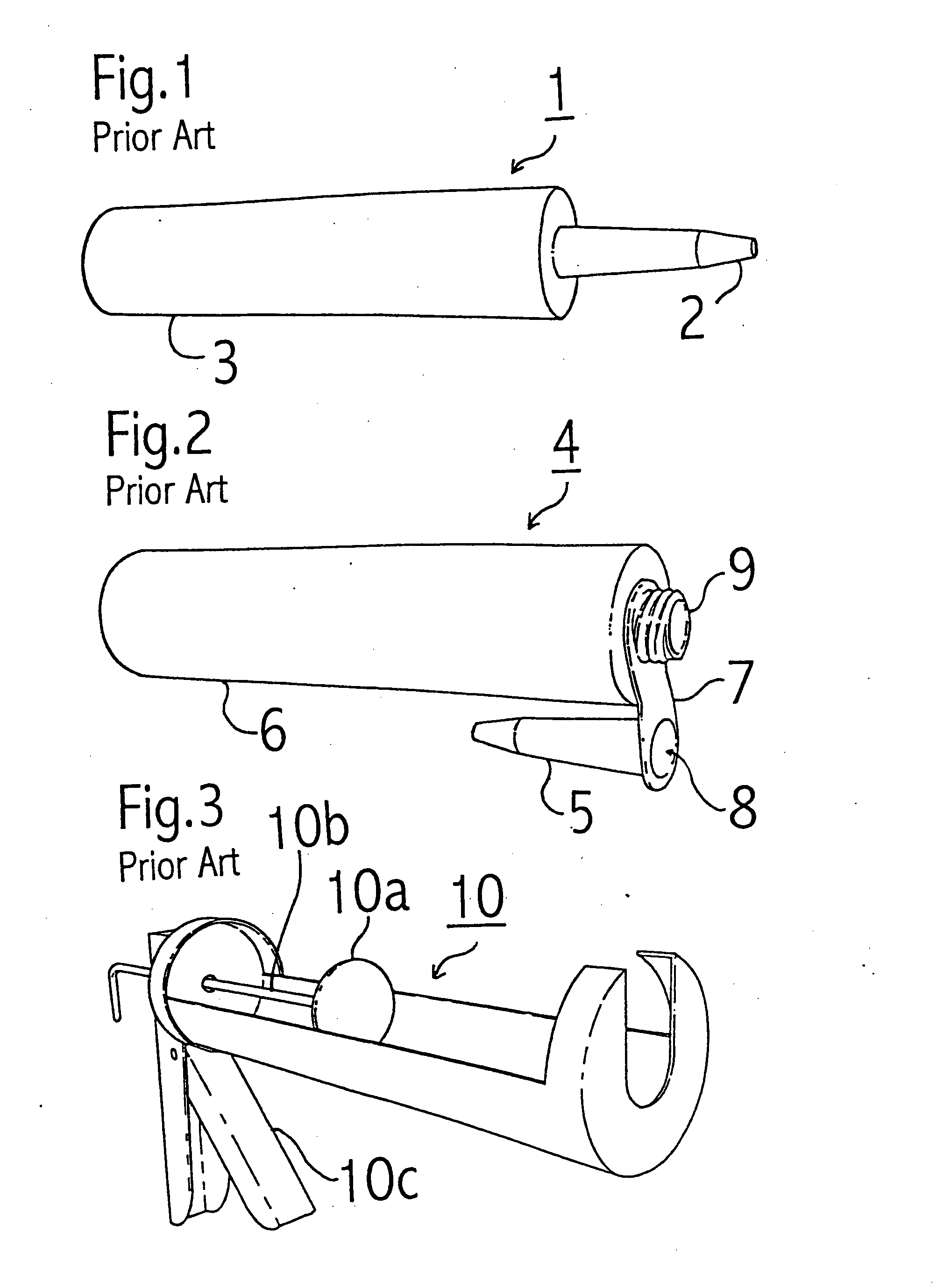

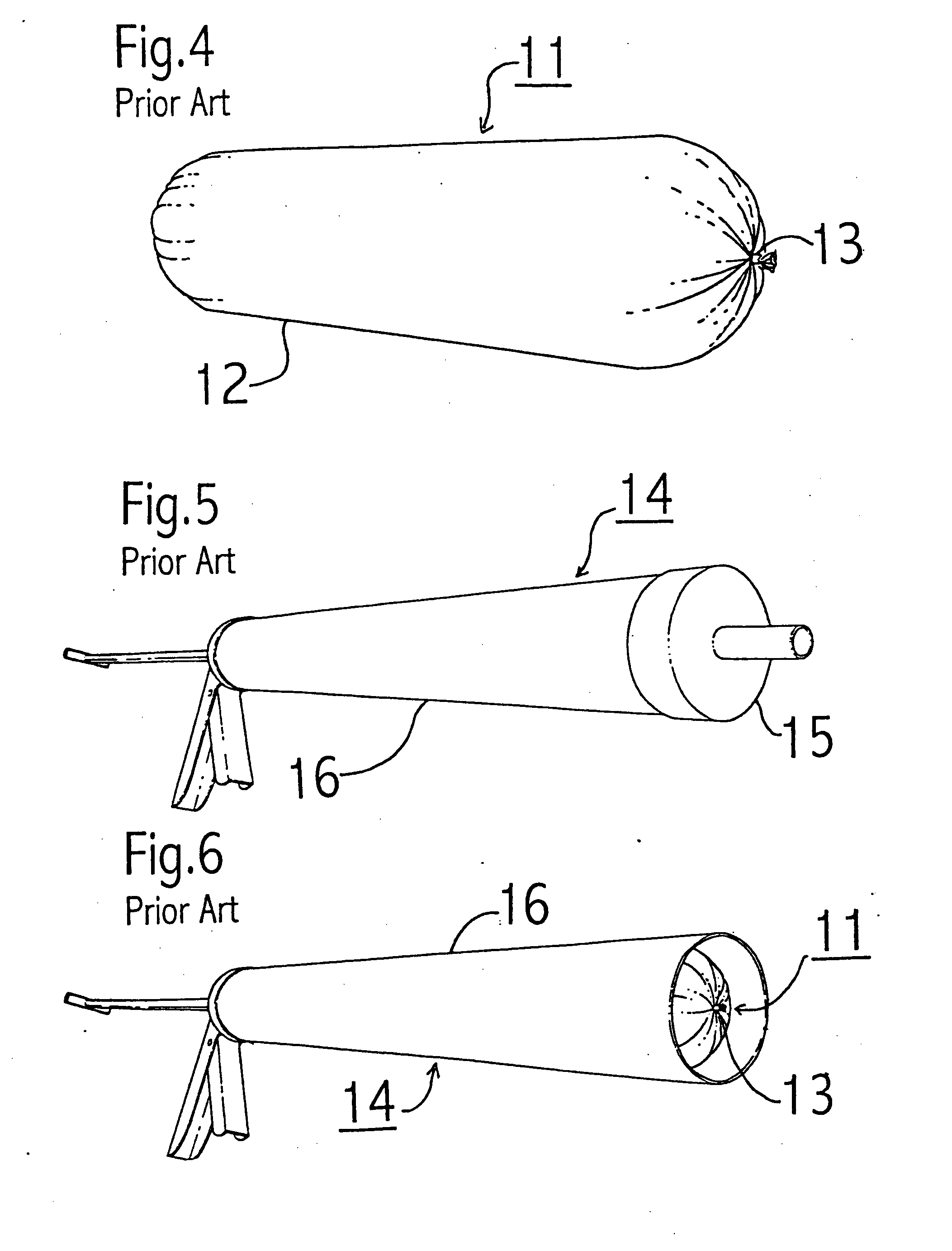

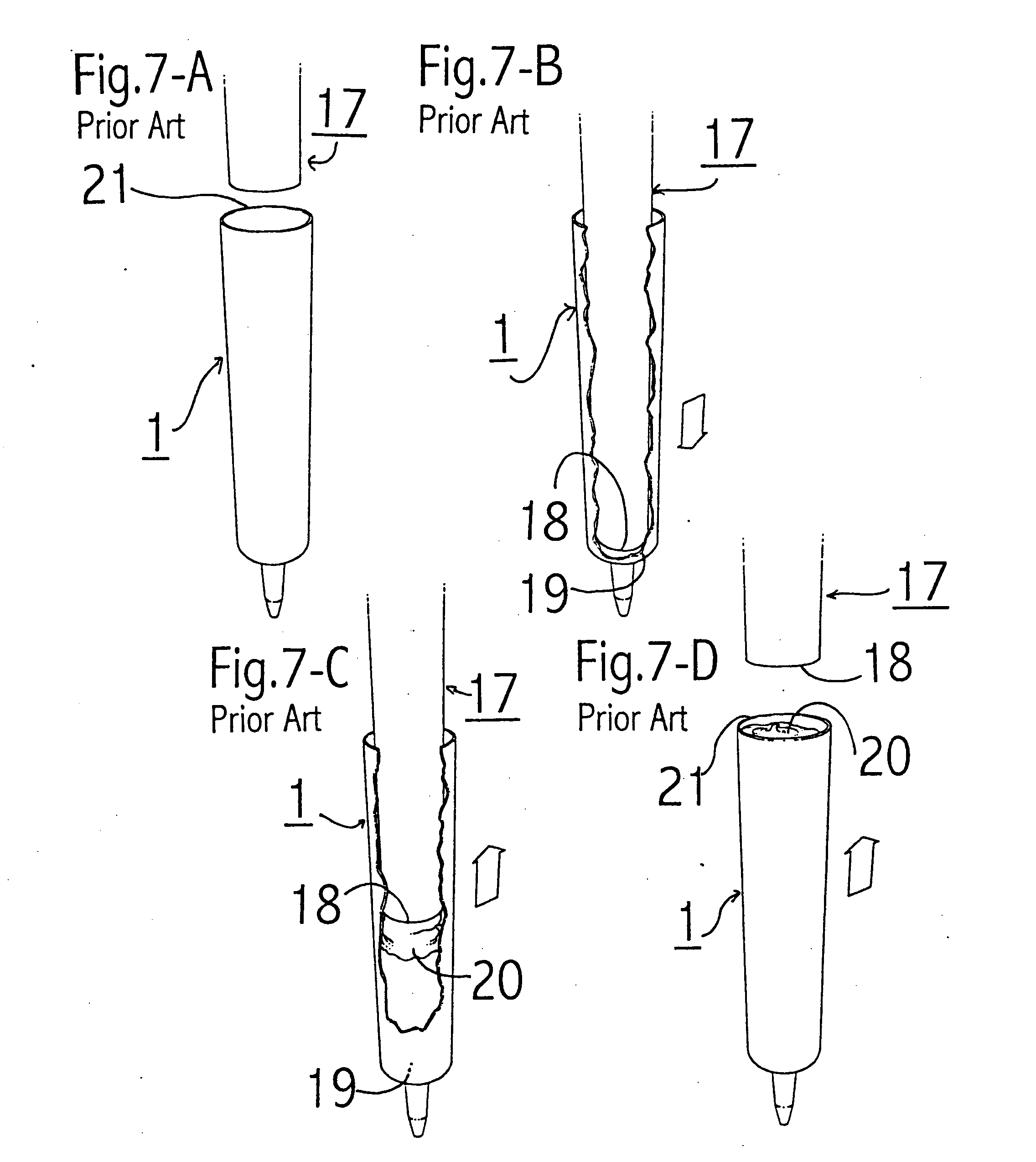

Method of filling dispensing cartridges having collapsible packages

InactiveUS20050198927A1Reduce pressureEliminate pressureLiquid surface applicatorsDispensing apparatusInternal pressurePack filling

A method of filling a collapsible package in a cartridge for use with a caulking gun is provided. The method comprises pressurizing an internal space of a collapsible package to expand the package. Drawing a vacuum external to the collapsible package and removing the positive internal pressure. The vacuum maintains the package in an expanded state. A nozzle is then inserted into the collapsible package to reverse fill the package with a vicious material.

Owner:SASHCO

Methods of making and filling a fill-through-the-top package

A fill-through-the-top reclosable package includes first and second opposing body panels joined to each other along a pair of sides and a bottom bridging the pair of sides. The package is provided with a reclosable fastener extending along a package top disposed opposite the bottom. The fastener includes first and second opposing tracks. The first track includes a male profile, while the second track includes a female profile adapted to releasably interlock with the male profile. To provide tamper evidence, the first and second tracks may be joined to each other along an area of weakness. When making the package, the first track is first attached to the first panel, the package is filled with a product via a fill opening between the second track and the second panel, and then the second track is attached to the second panel.

Owner:REYNOLDS PRESTO PRODS

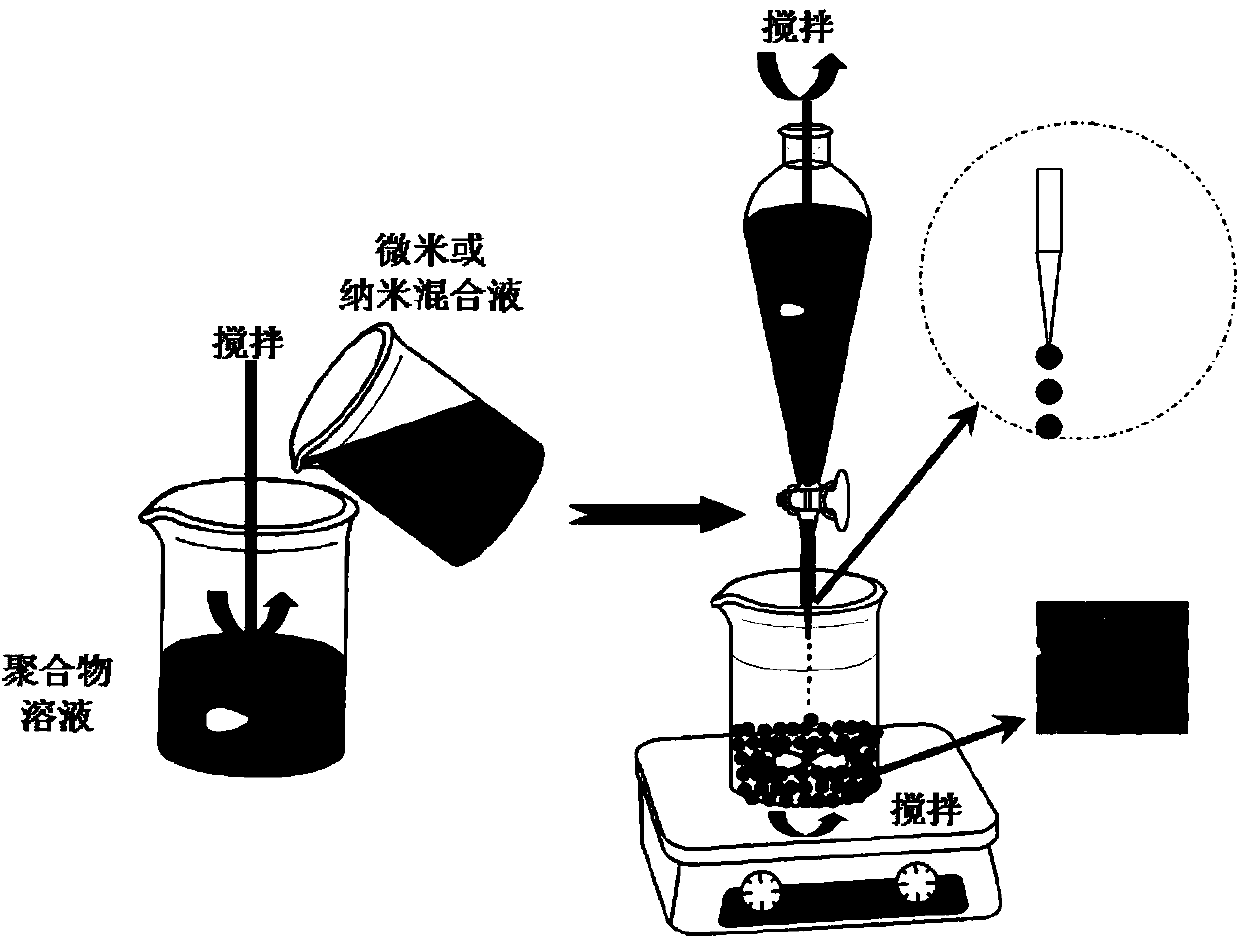

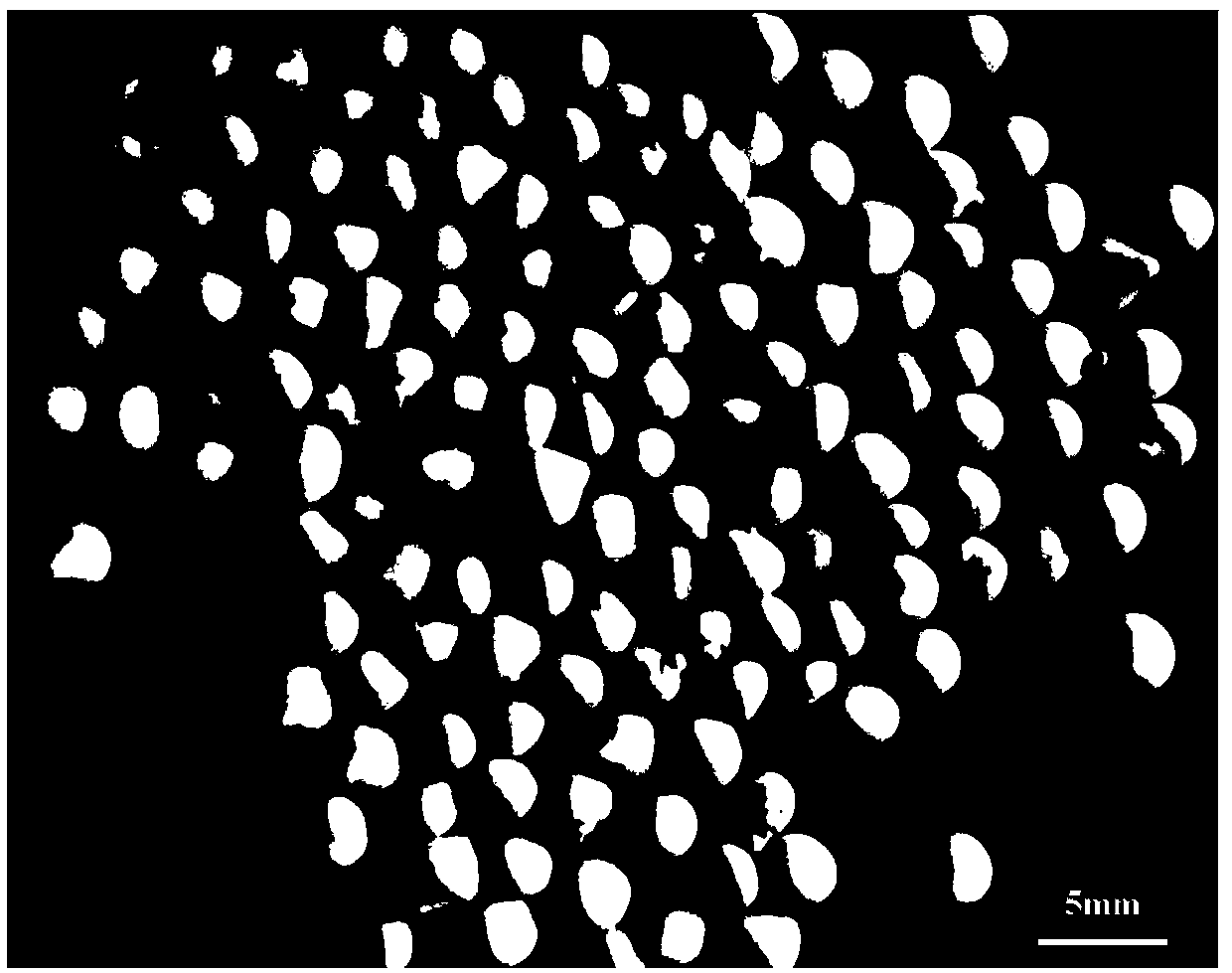

Preparation method for polymer matrix micron/nanometer packing filling modification compound premix particles

The invention relates to a preparation method for polymer matrix micron / nanometer packing filling modification compounding premix particles. The preparation method comprises the following steps: dissolving a water-insoluble polymer matrix into a first water-soluble solvent to obtain a homogeneous polymer solution; dispersing the micron / nanometer packing into a second water-soluble solvent, and conducting stirring, heating, and ultrasonic treatment, adding a solubilizer or a coupling agent so as to obtain homogeneous micron / nanometer packing dispersing liquid; adding the homogeneous micron / nanometer packing dispersing liquid into the homogeneous polymer solution, and mixing uniformly to obtain a homogeneous solution system solution; dropwise adding the homogeneous solution system solution into a container filled with deionized water, wherein the dropwise-added liquid is rapidly coagulated into round particles with uniform particle diameters; collecting the round particles in the container and cleaning repeatedly; drying to obtain the polymer matrix micron / nanometer packing filling modification compound premix particles. According to the method provided by the invention, the method is simple, the cost is low, the agglomeration of the nanometer packing in the polymer matrix can be reduced effectively, the infiltration adsorption effect of the polymer matrix on inorganic packing is improved, the interface bonding strength of the polymer matrix and the inorganic packing is enhanced, and the filling modification effect is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

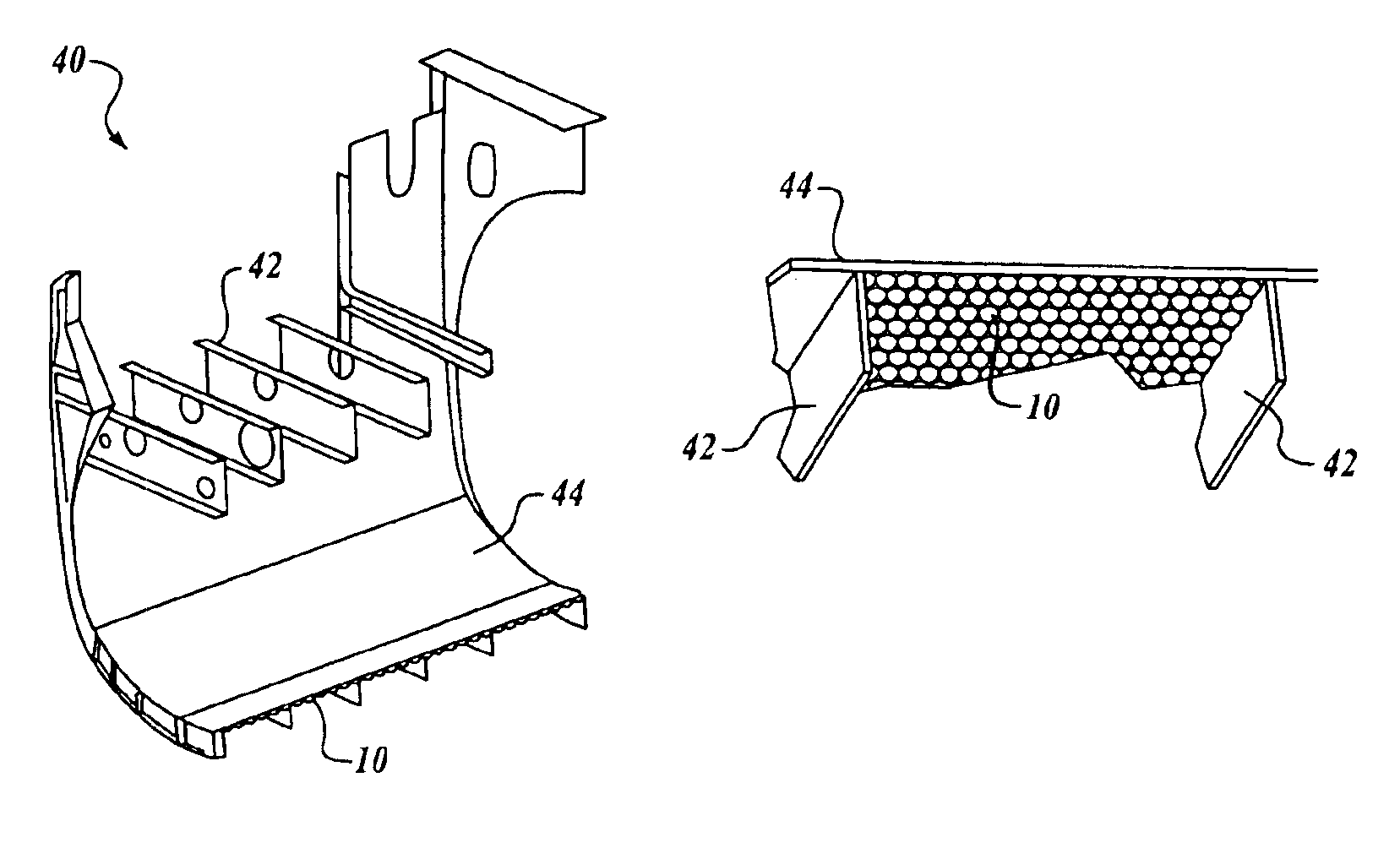

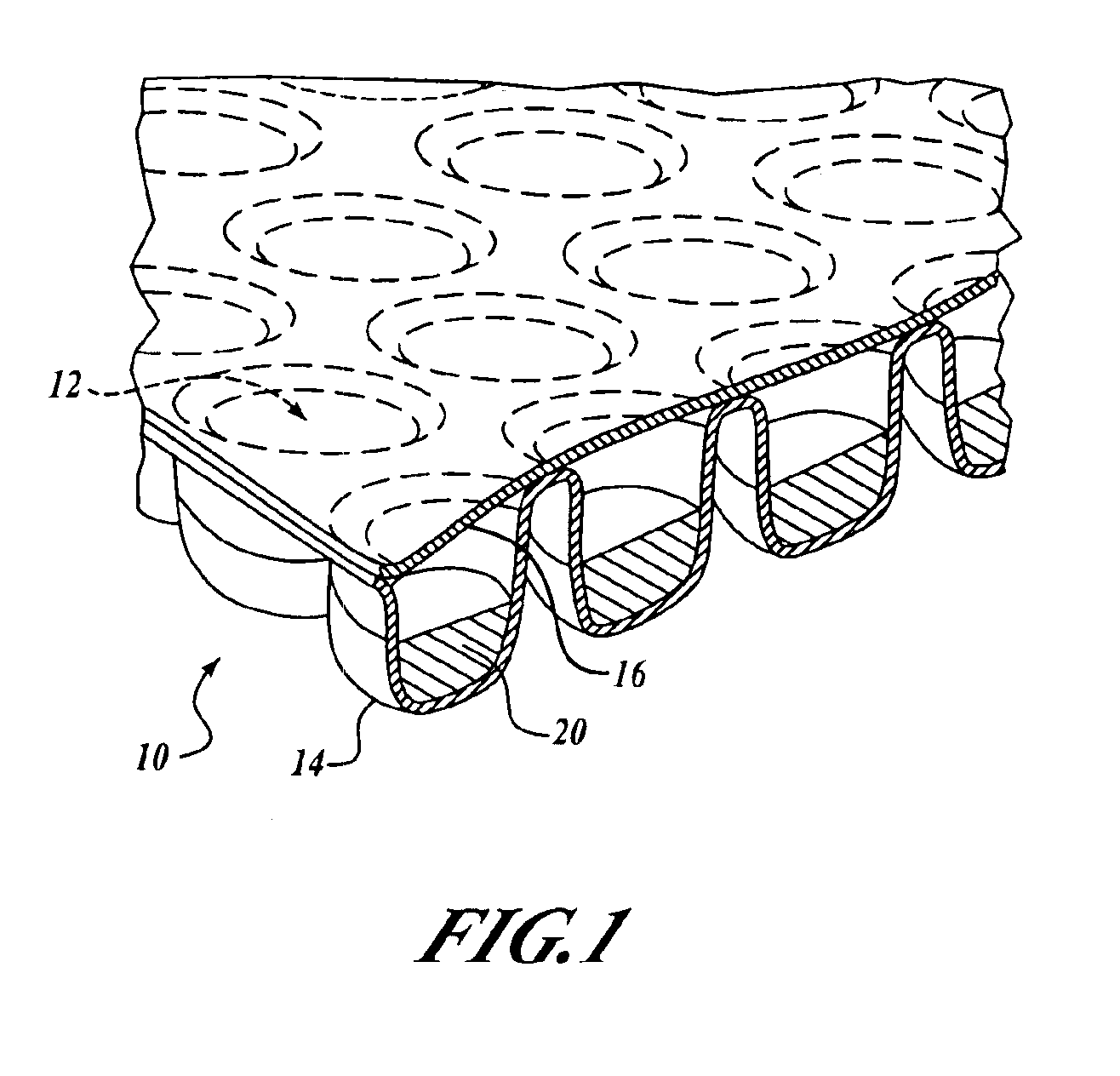

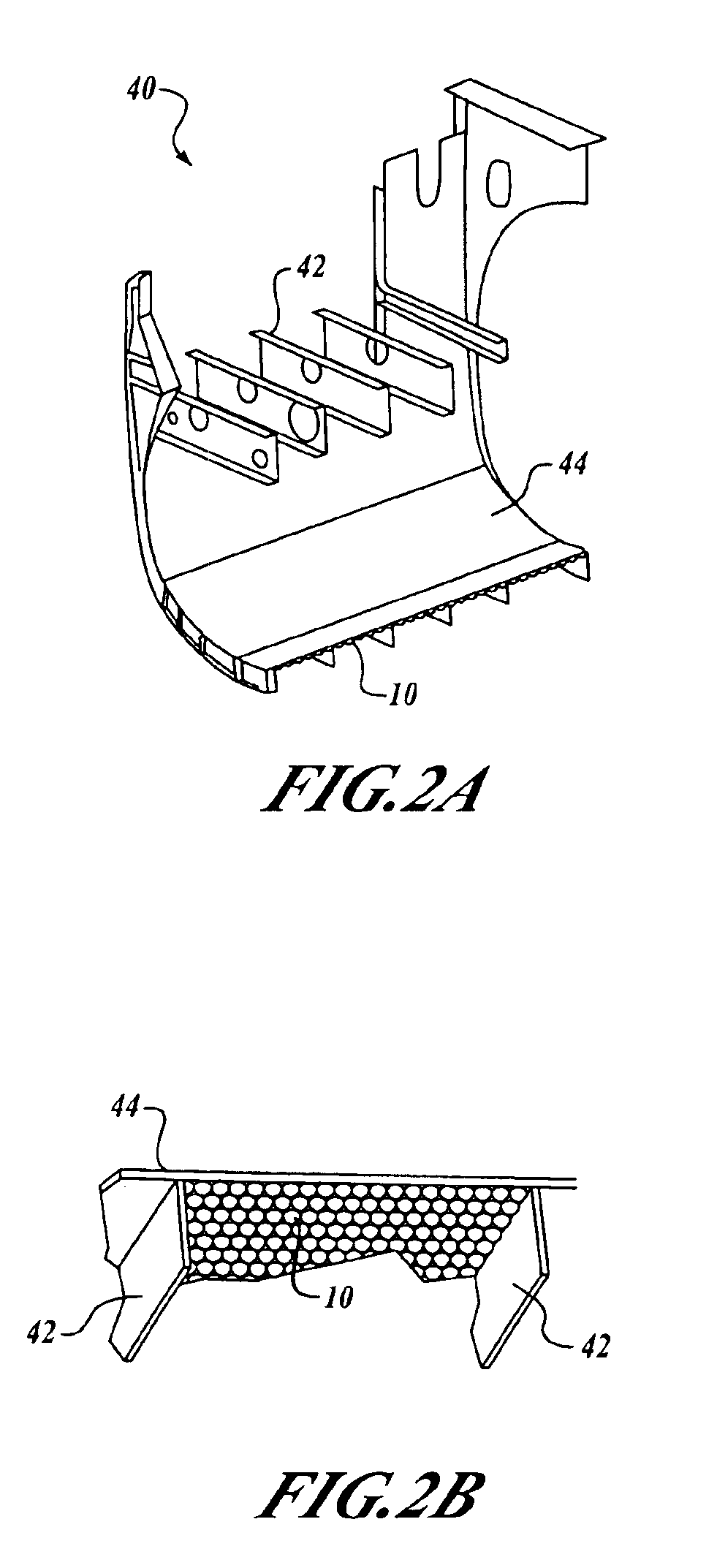

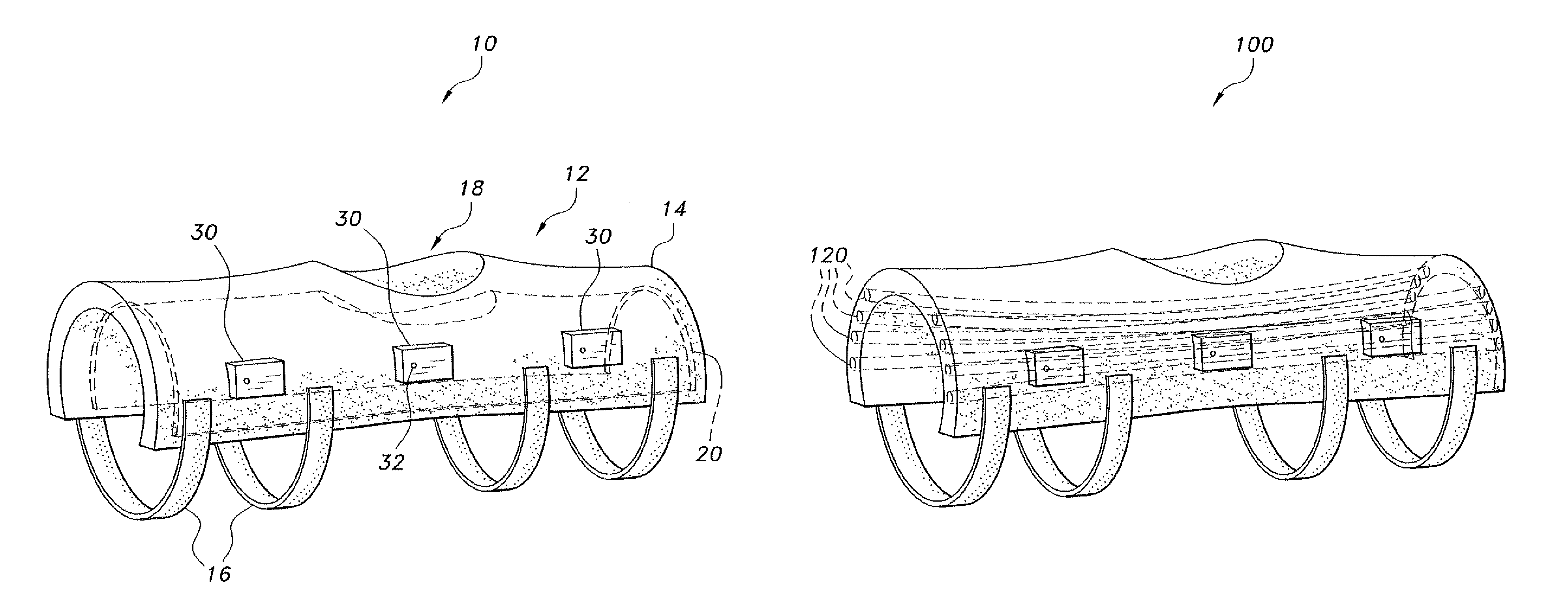

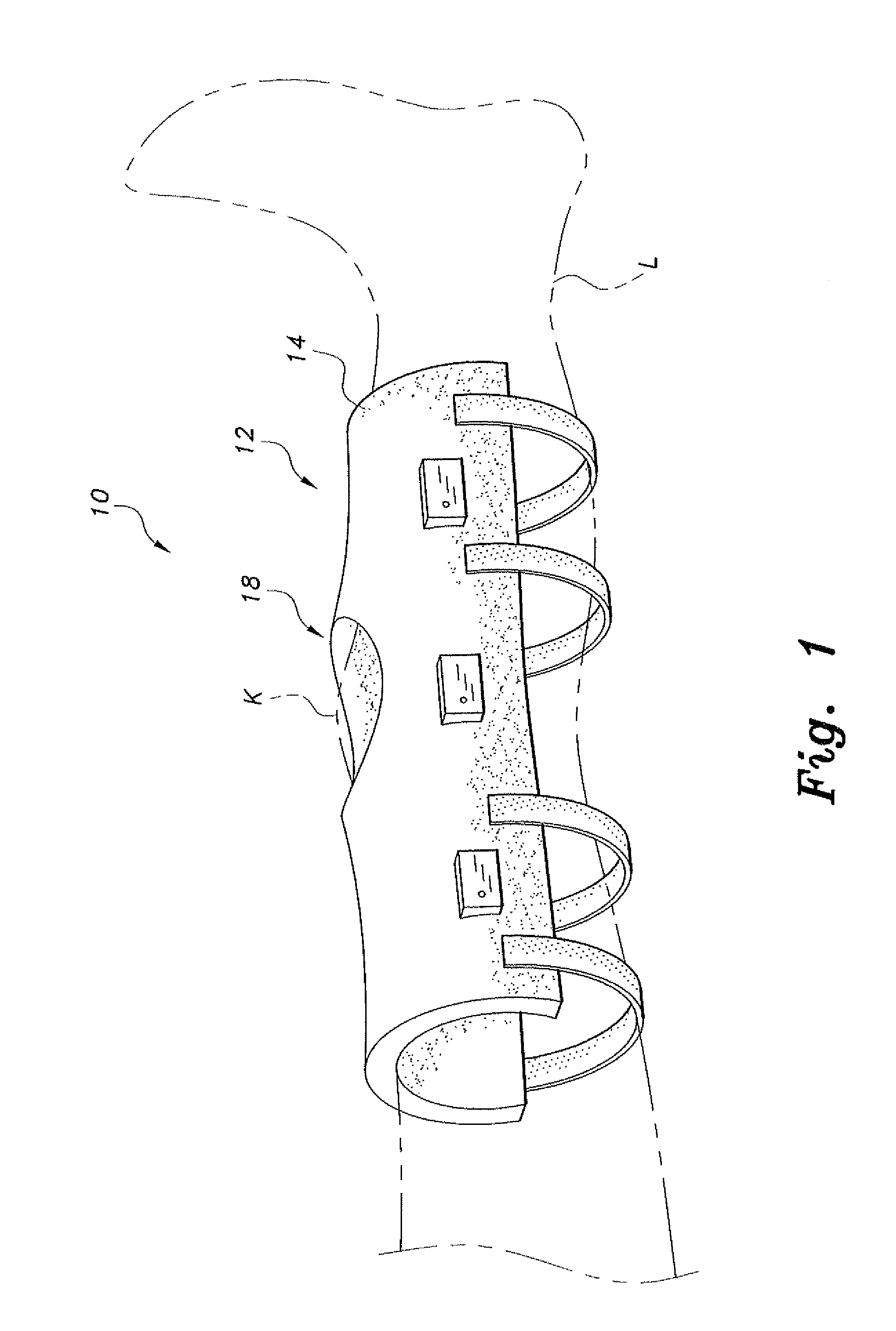

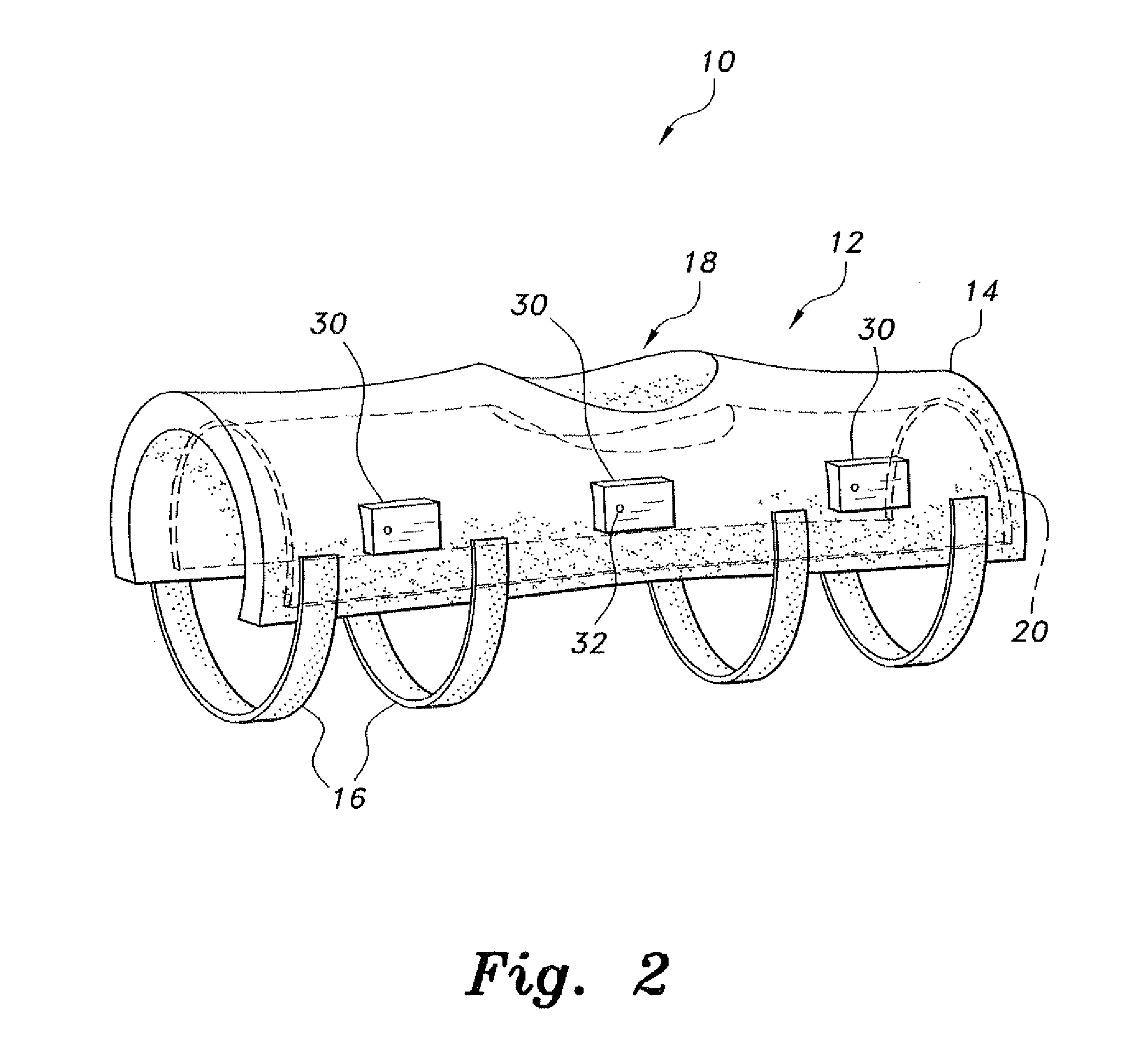

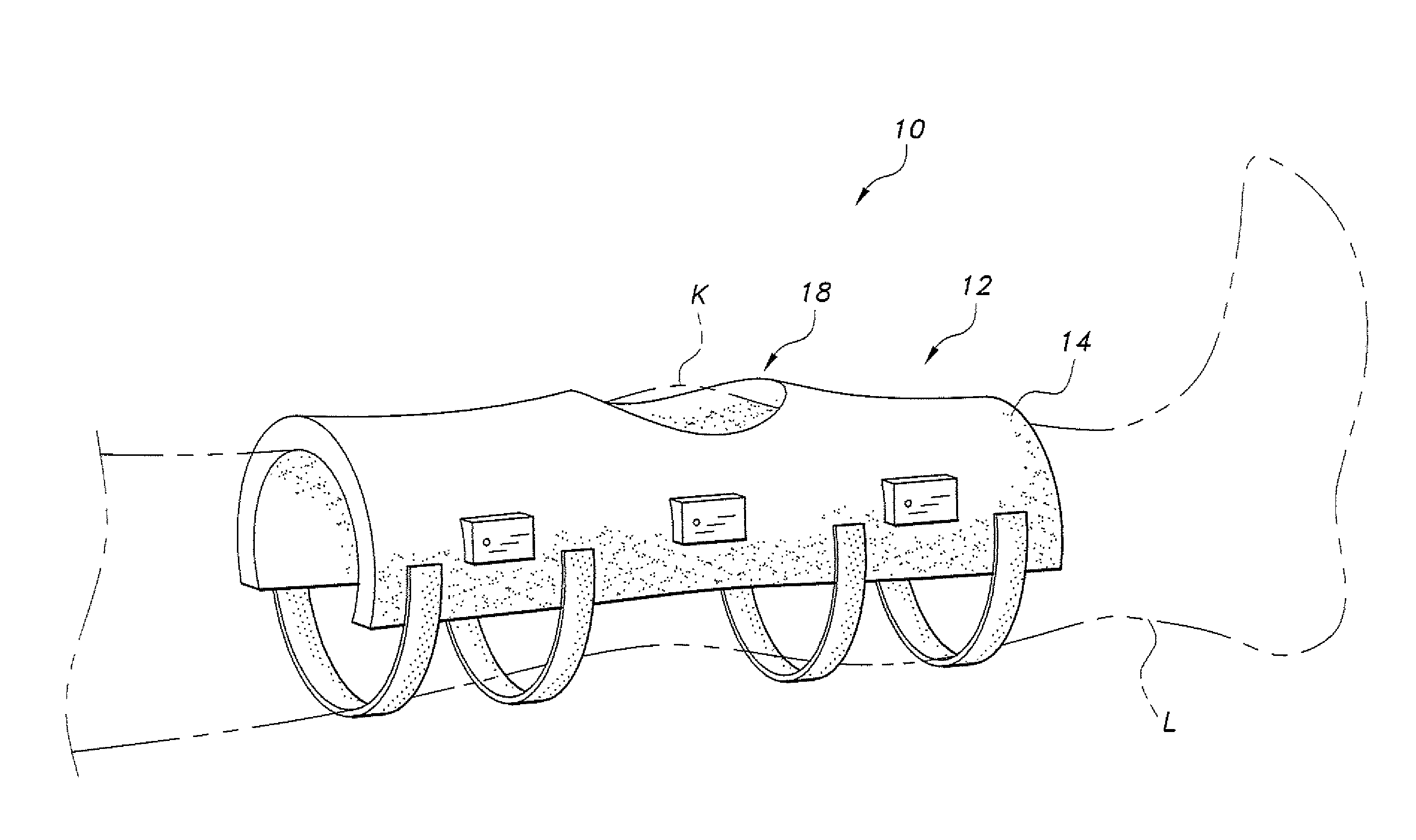

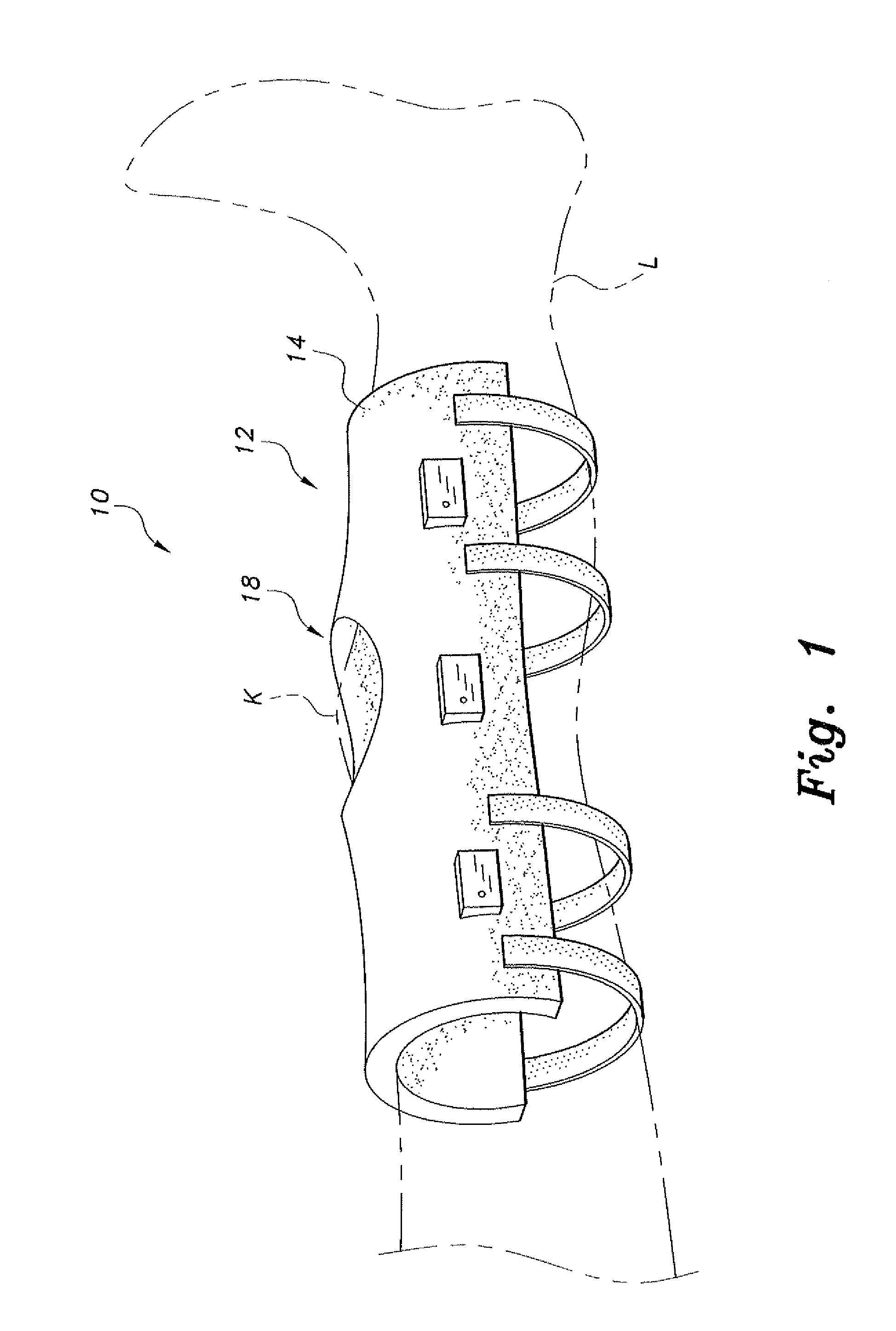

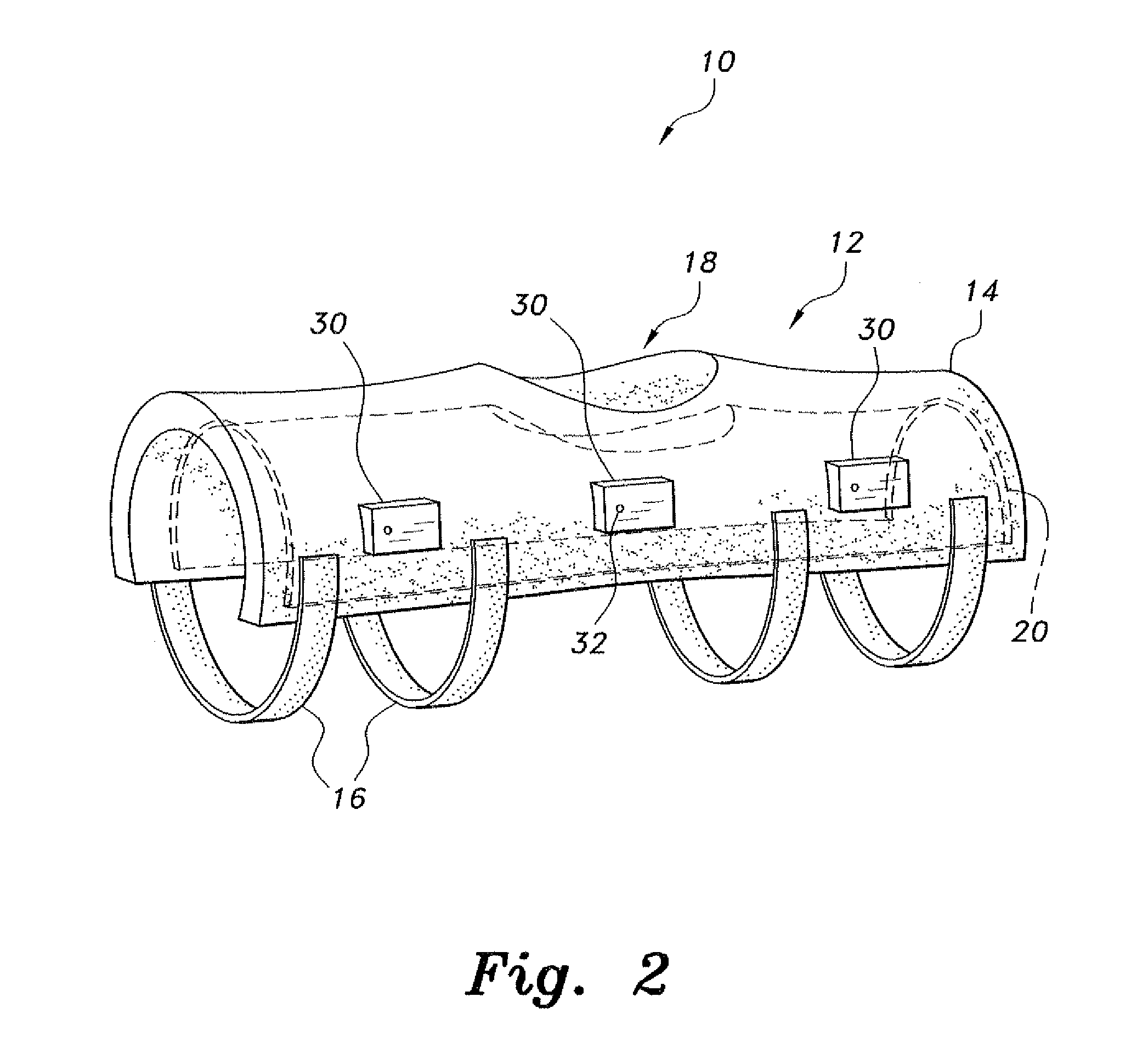

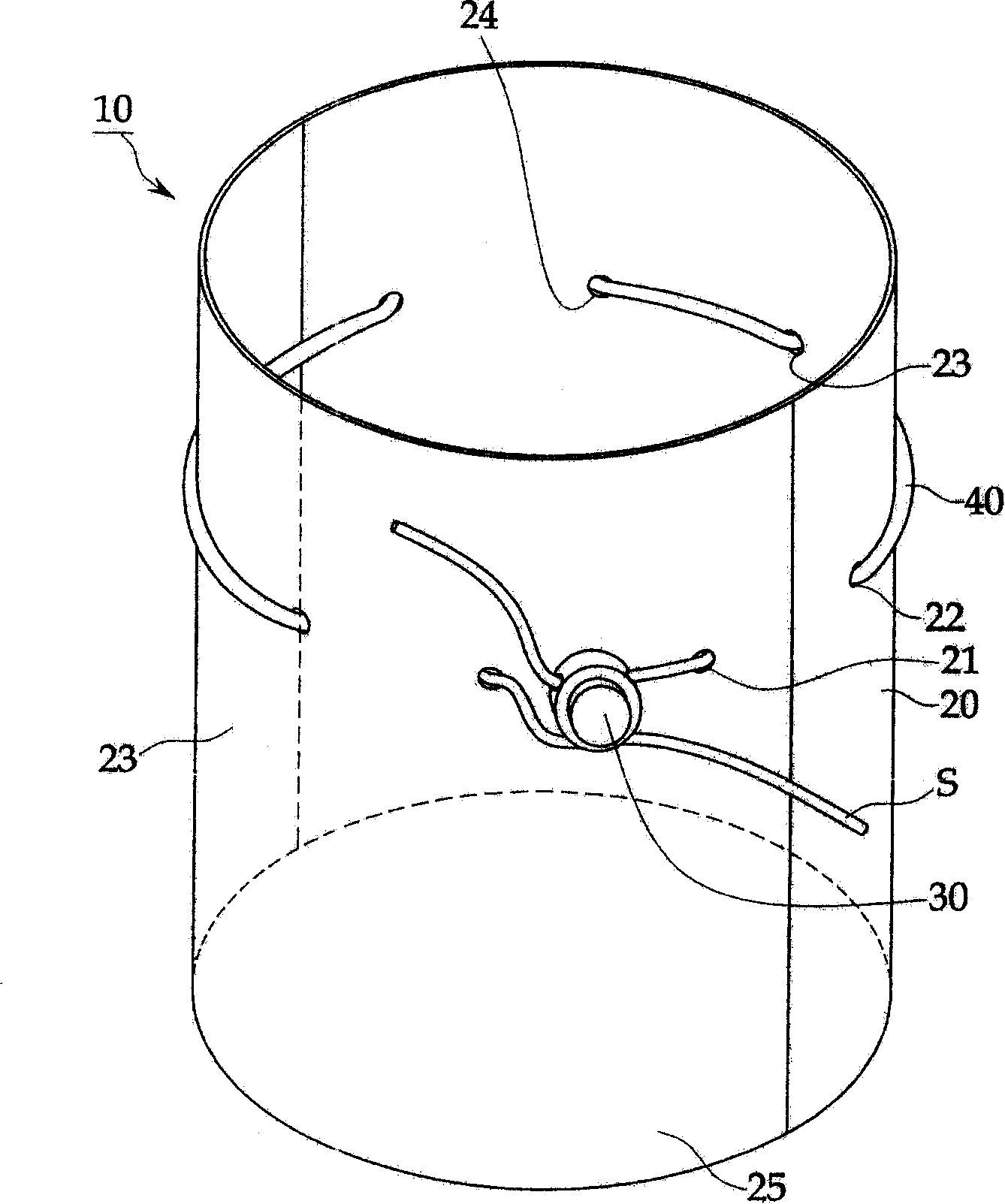

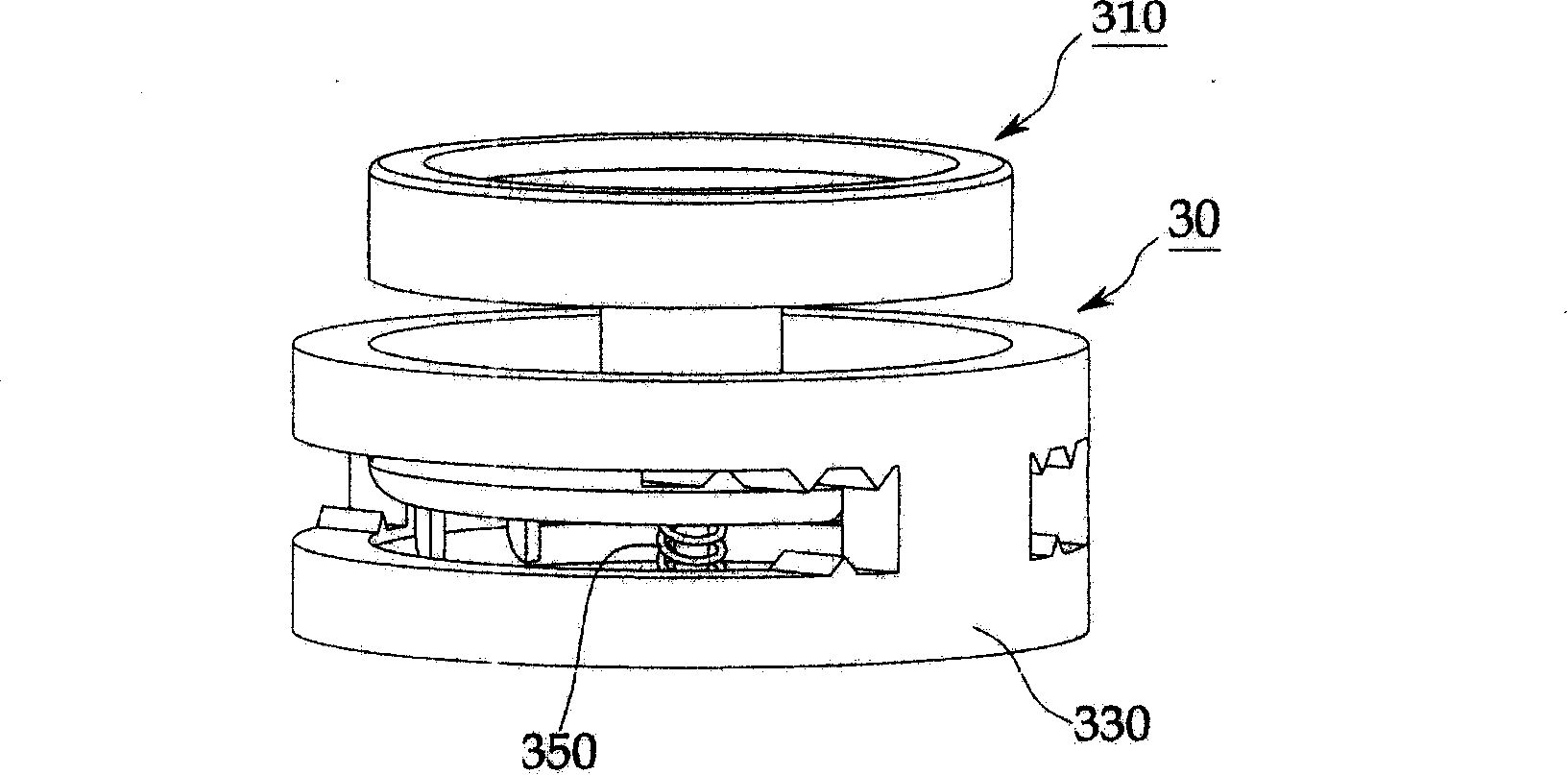

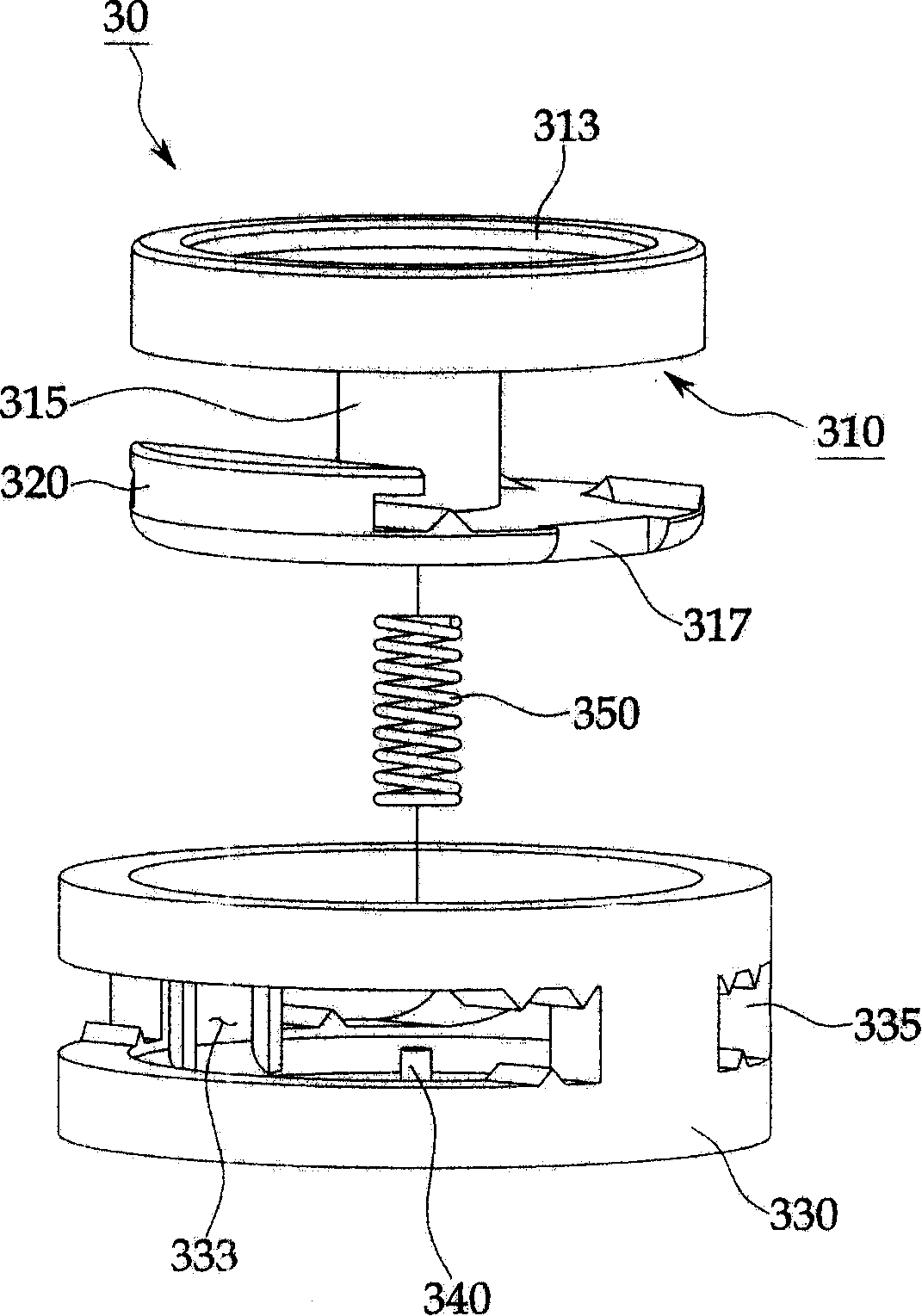

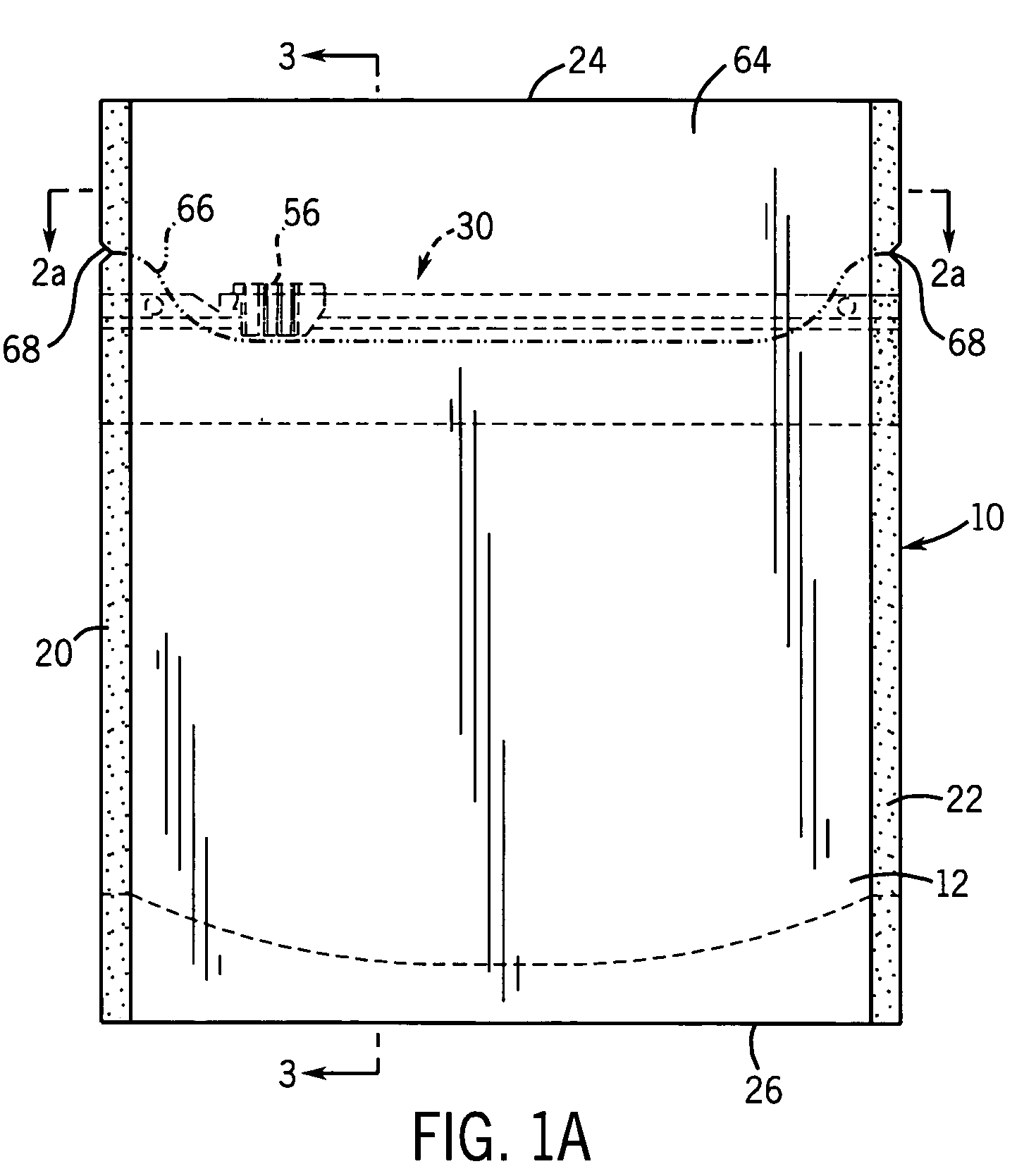

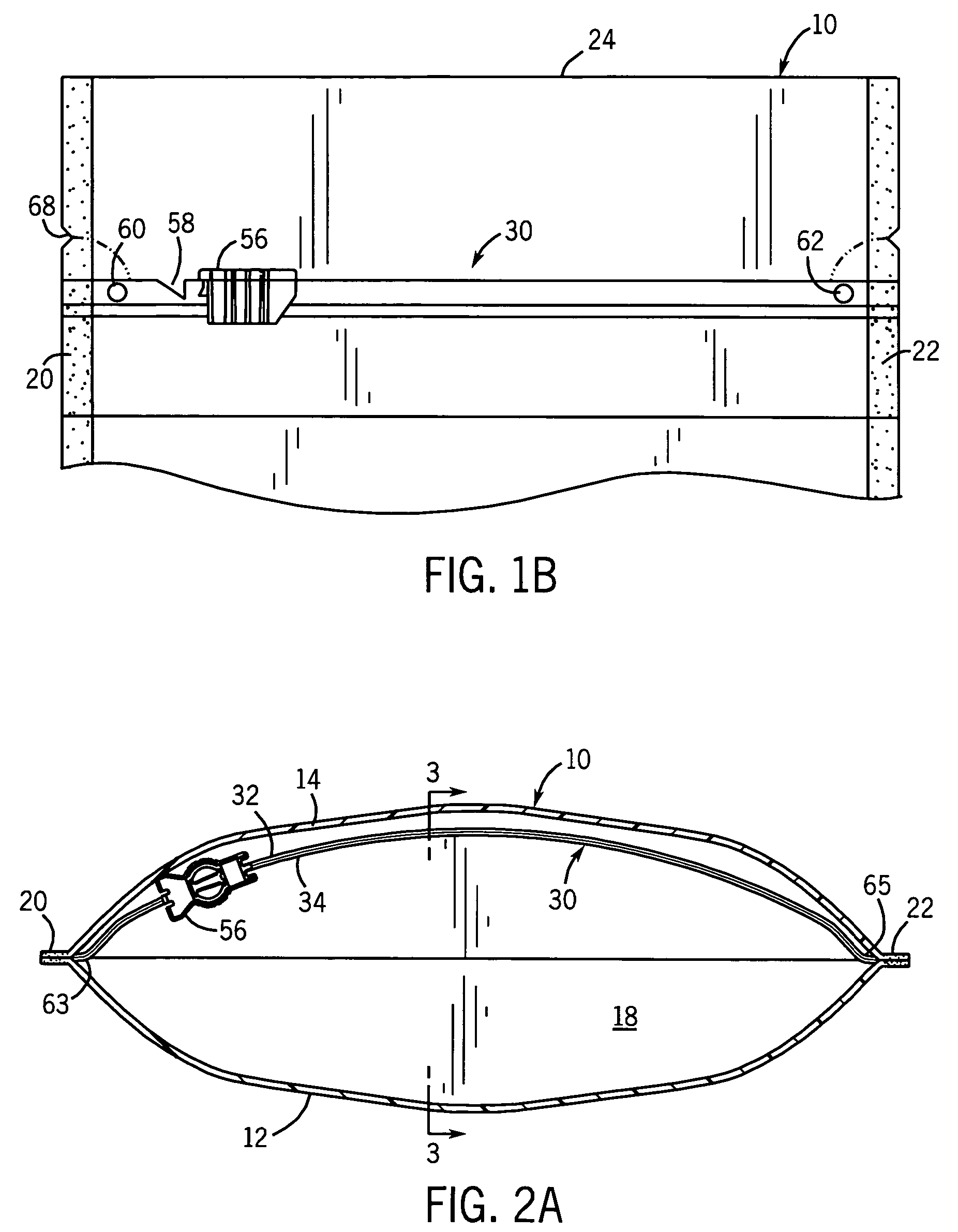

Magnetorheological medical brace

ActiveUS8696610B2Increase and decreases stiffnessElectrotherapyMagnetotherapy using coils/electromagnetsMagnetorheological fluidEngineering

The magnetorheological (MAR) medical brace includes a flexible outer shell that fits around the anatomical area to be braced and a plurality of adjustable straps for securing the shell onto the anatomical area. The shell encases a MAR pack filled with magnetorheological fluid or gel. A plurality of magnets is attached to or encased in the shell to provide a magnetic field acting on the MAR pack. The interaction of the magnetic field with the MAR pack adjustably increases or decreases the stiffness of the shell depending on the strength of the magnetic field. A control mechanism is provided for selective adjustment of the magnetic field and other functions.

Owner:SOLOMON CLIFFORD T +1

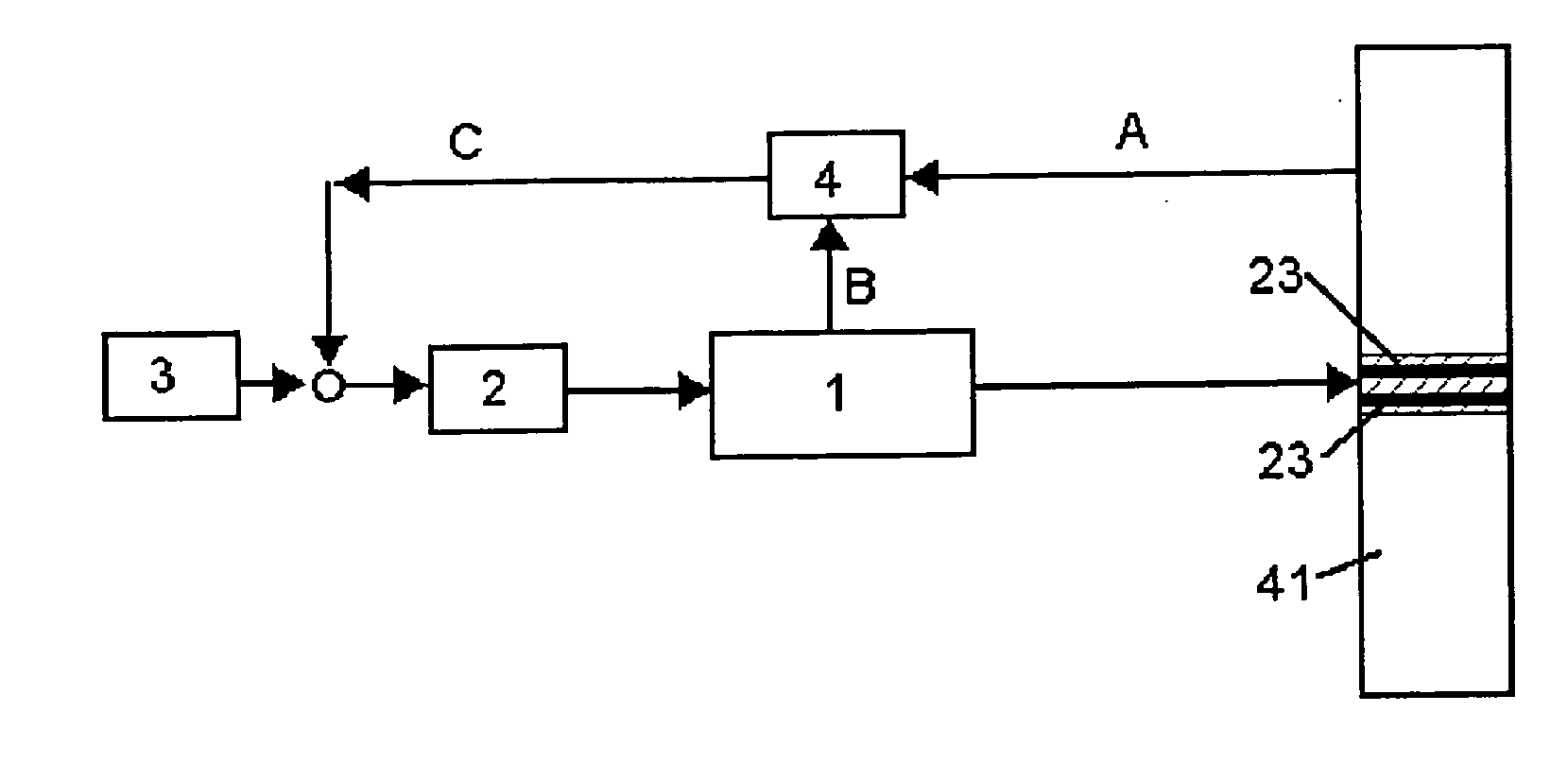

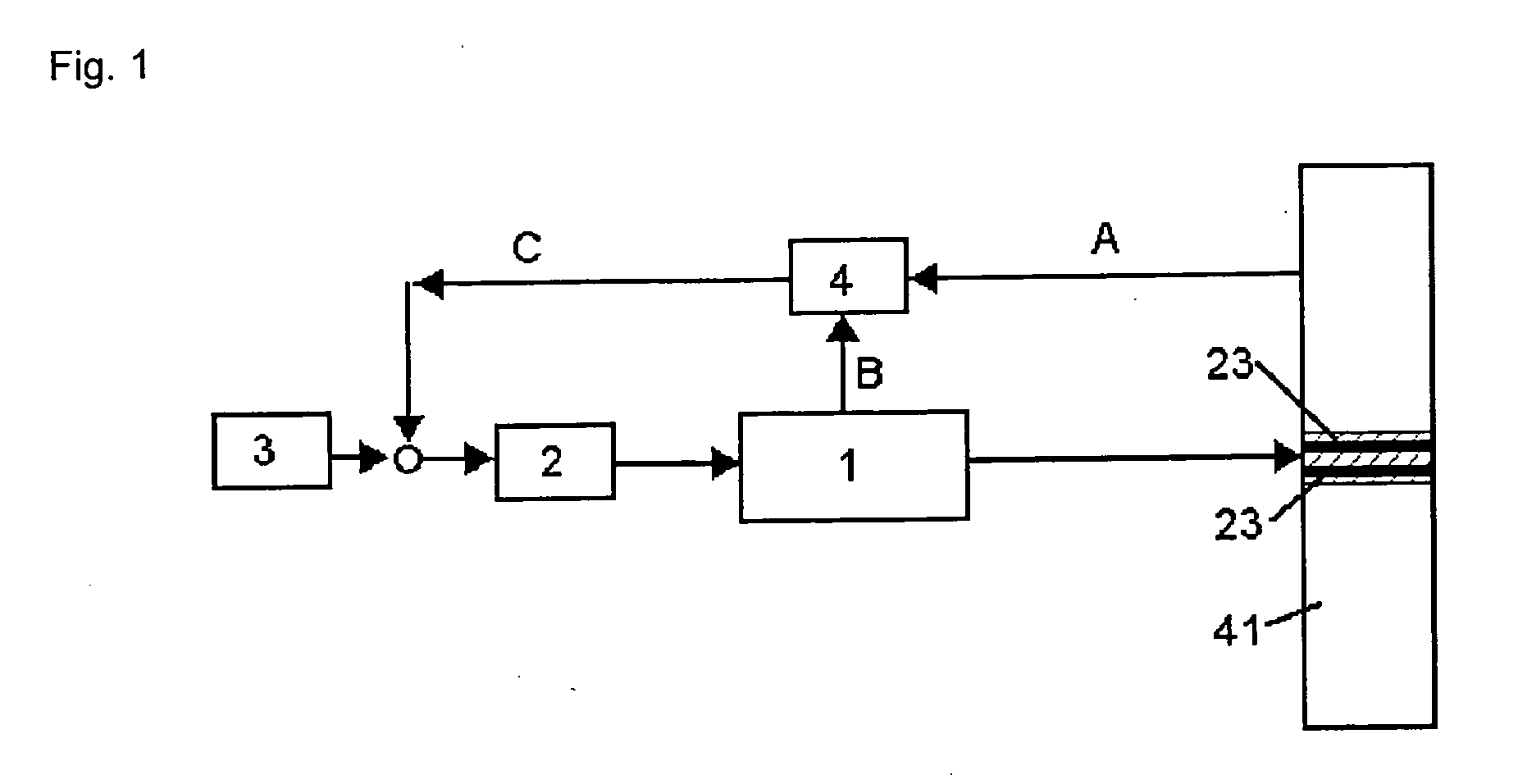

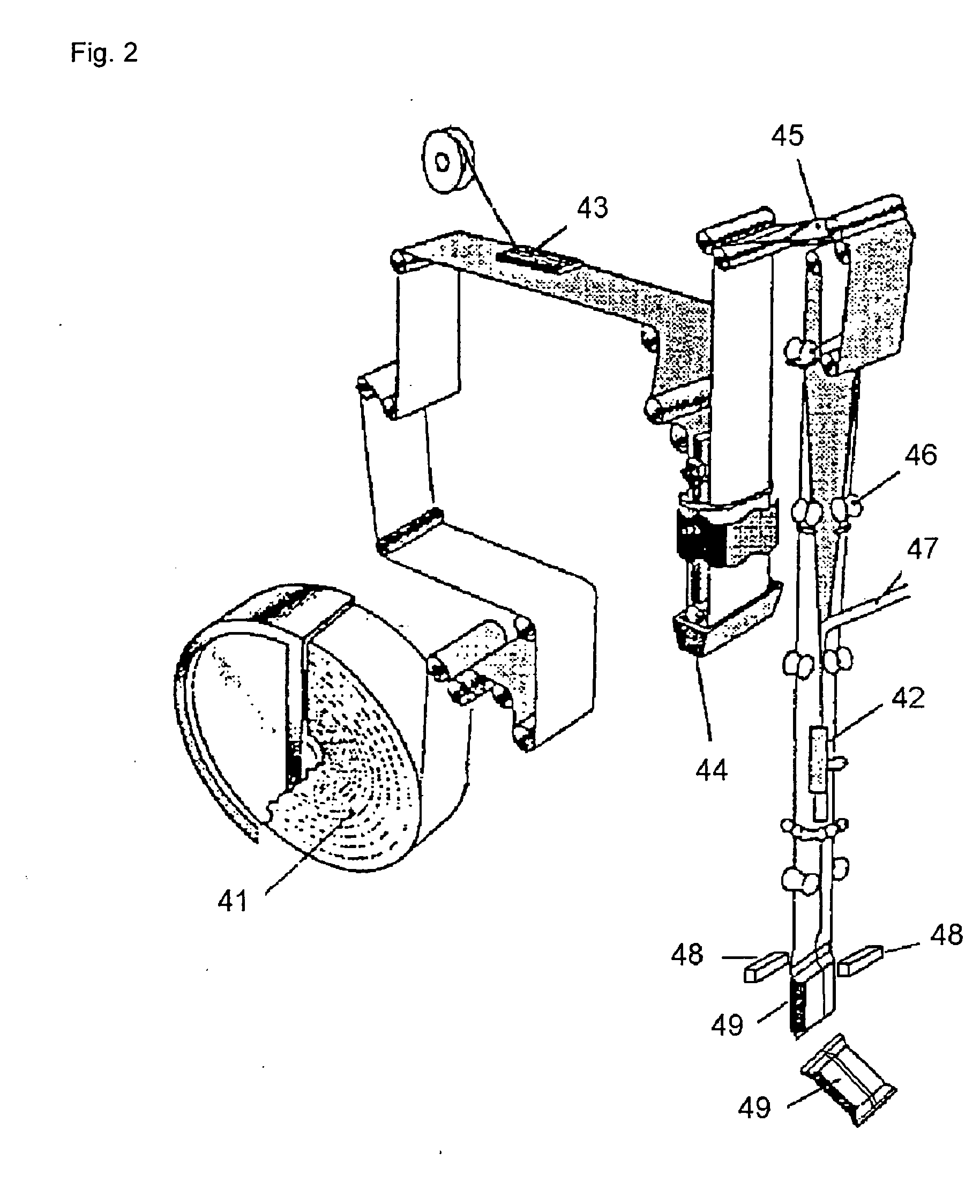

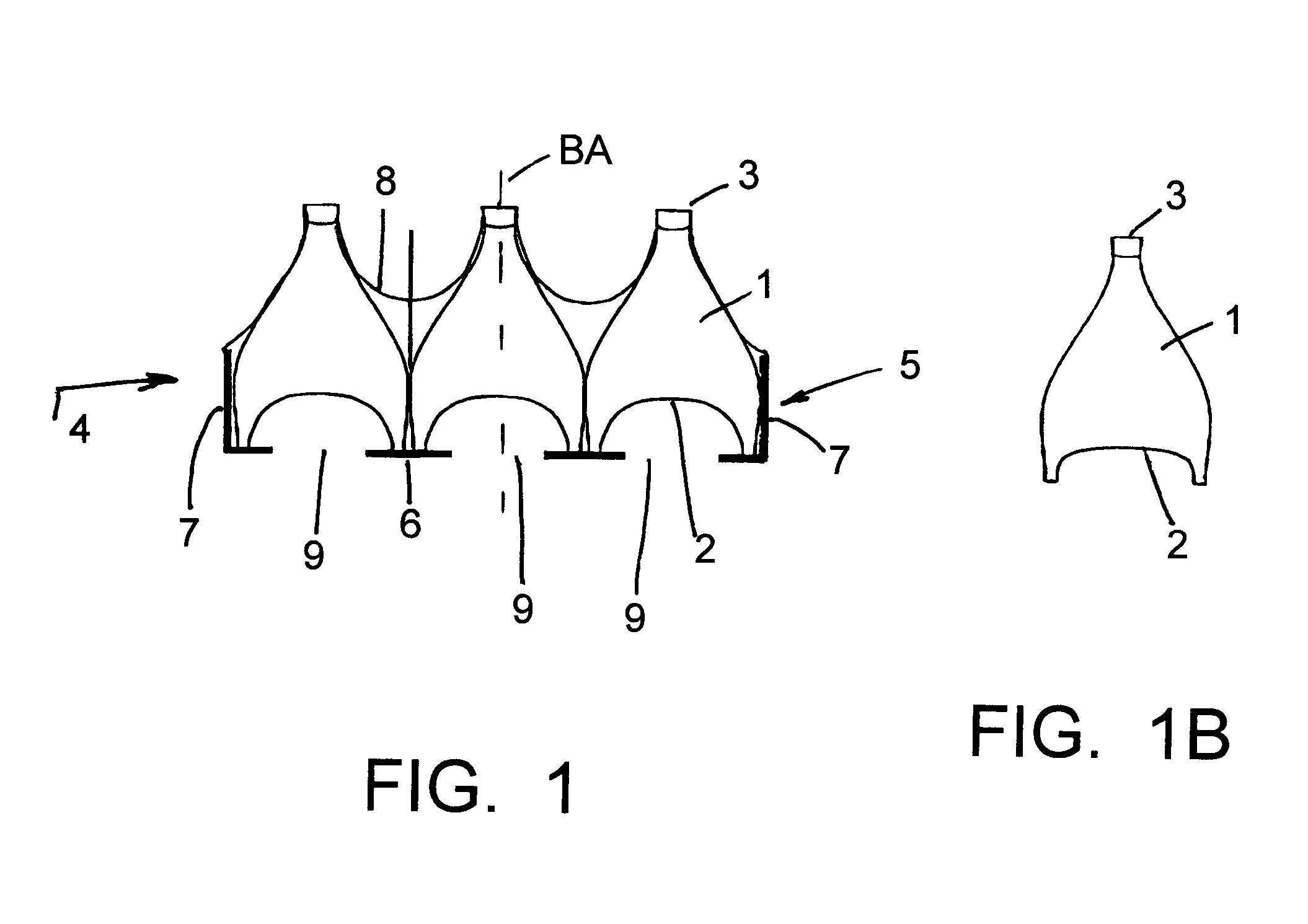

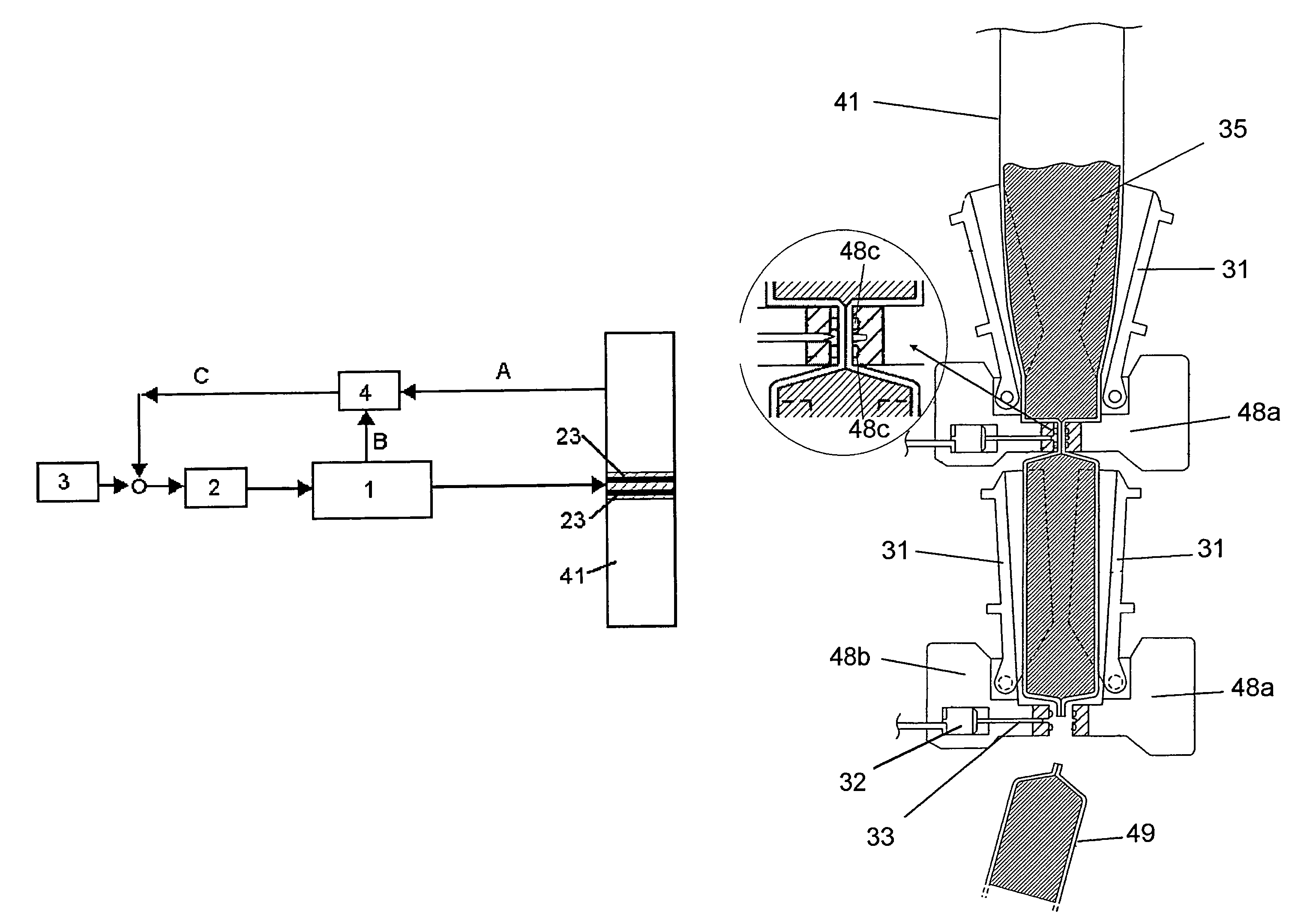

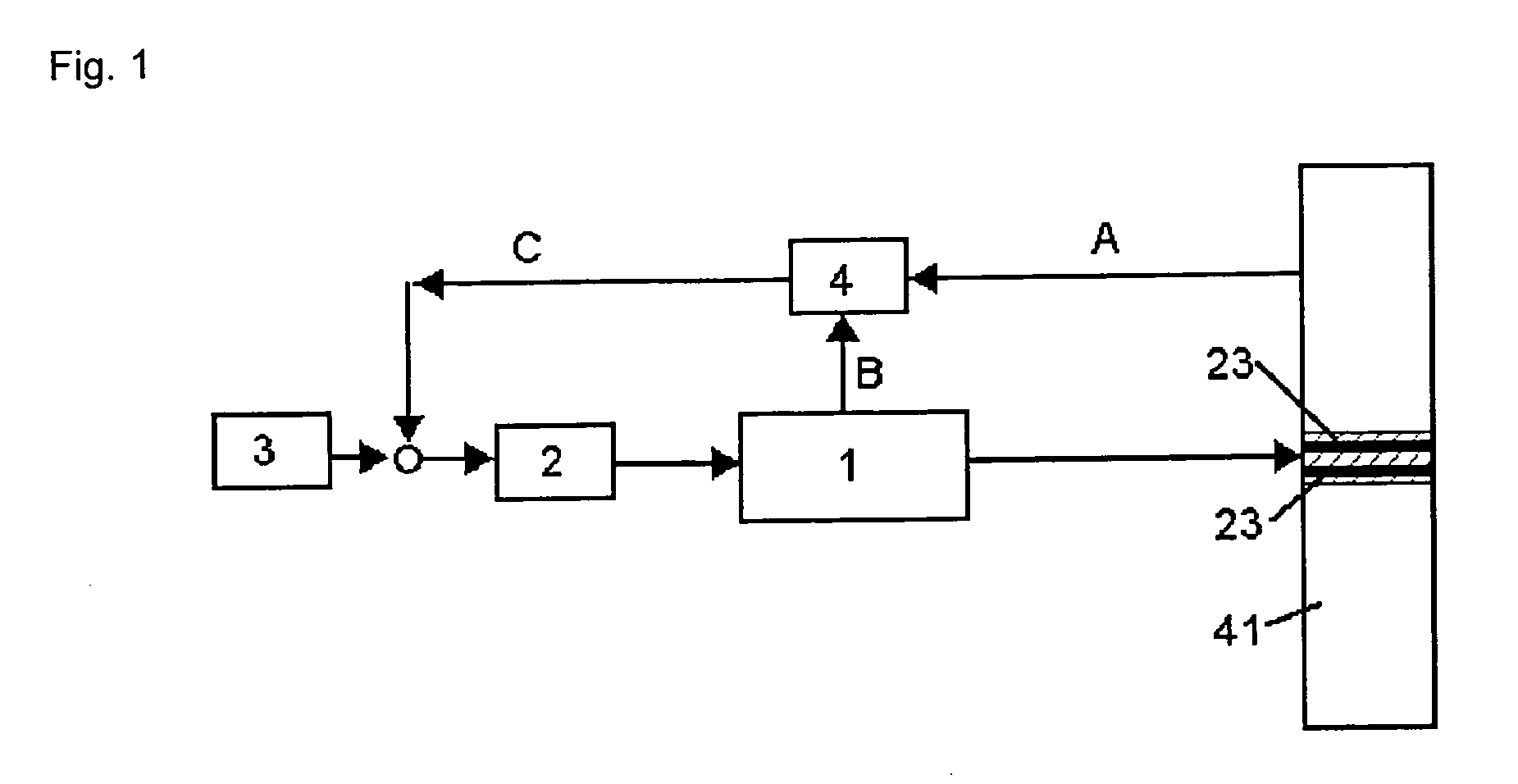

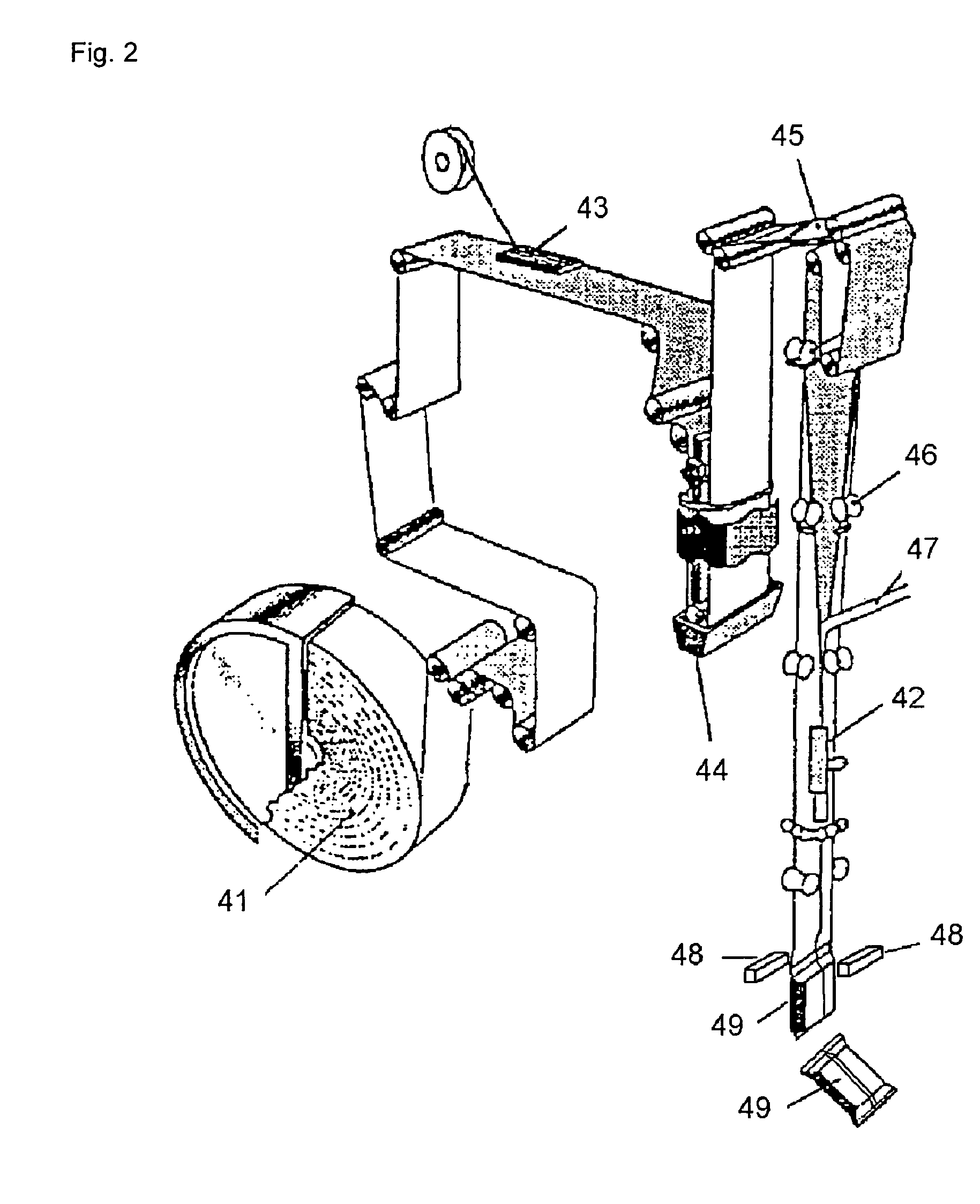

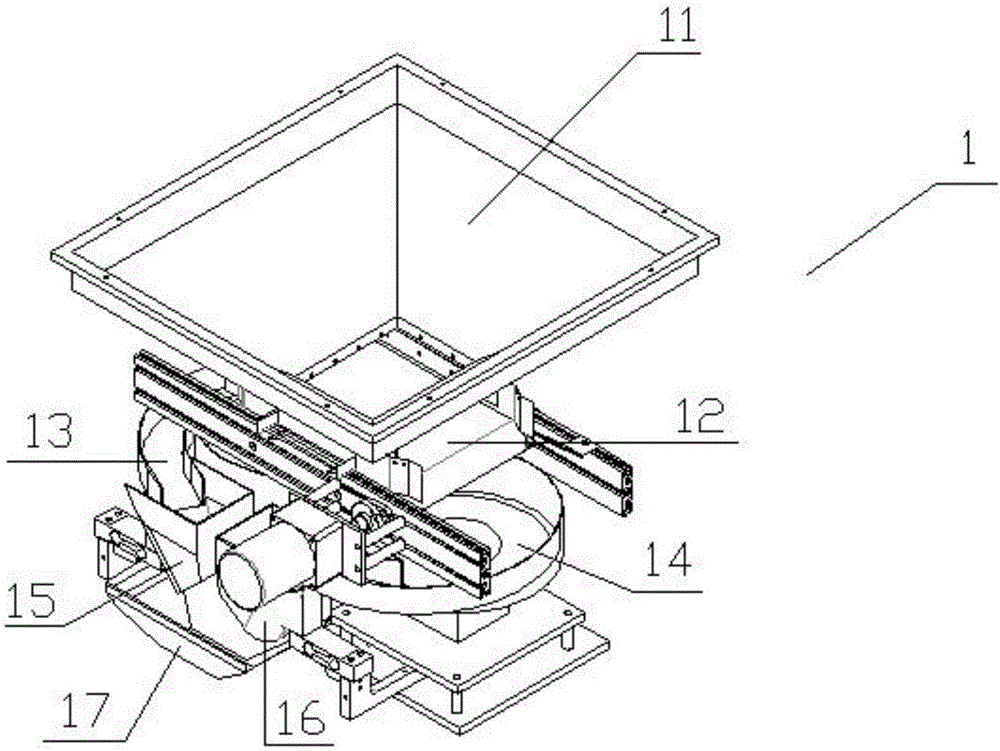

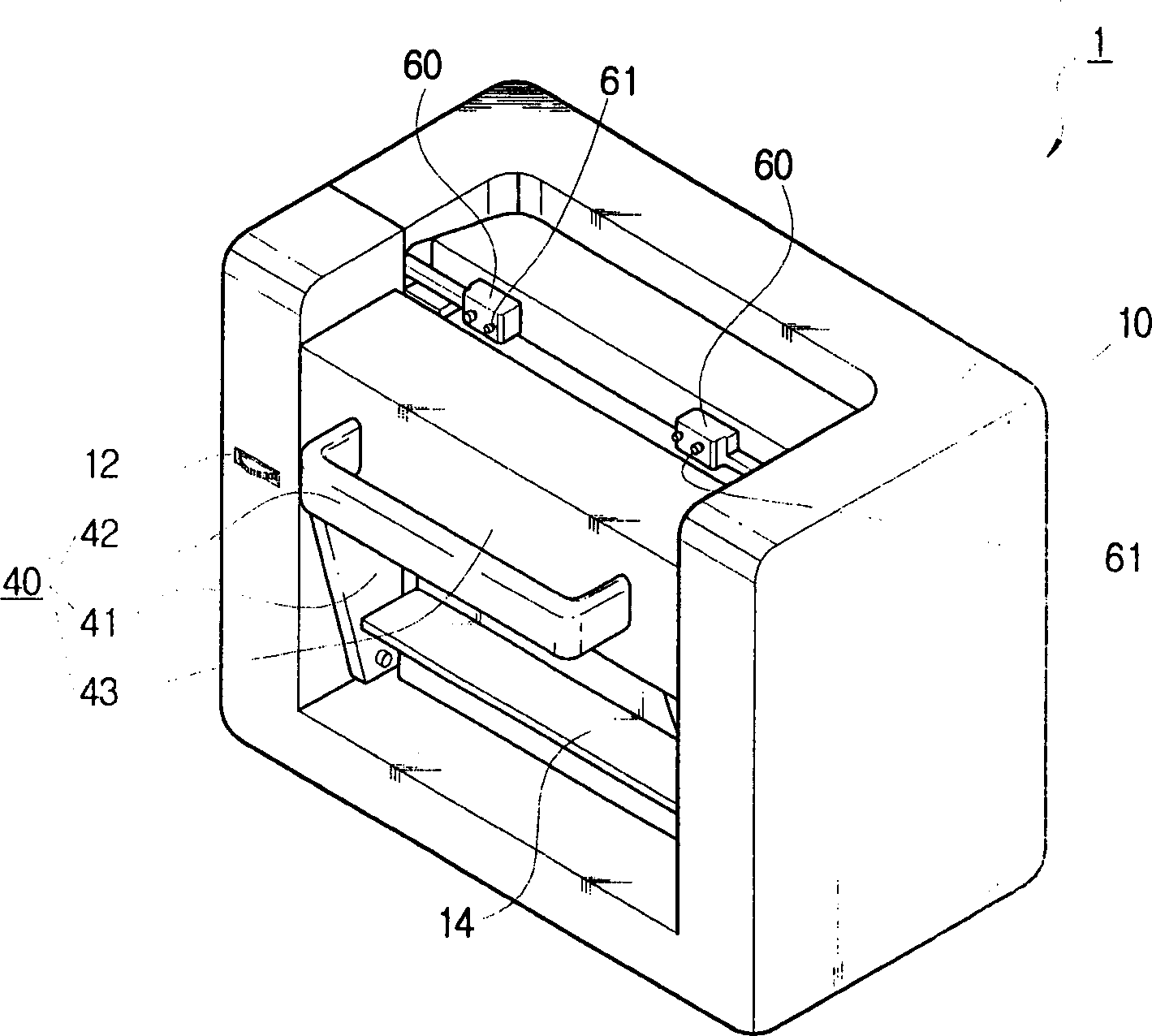

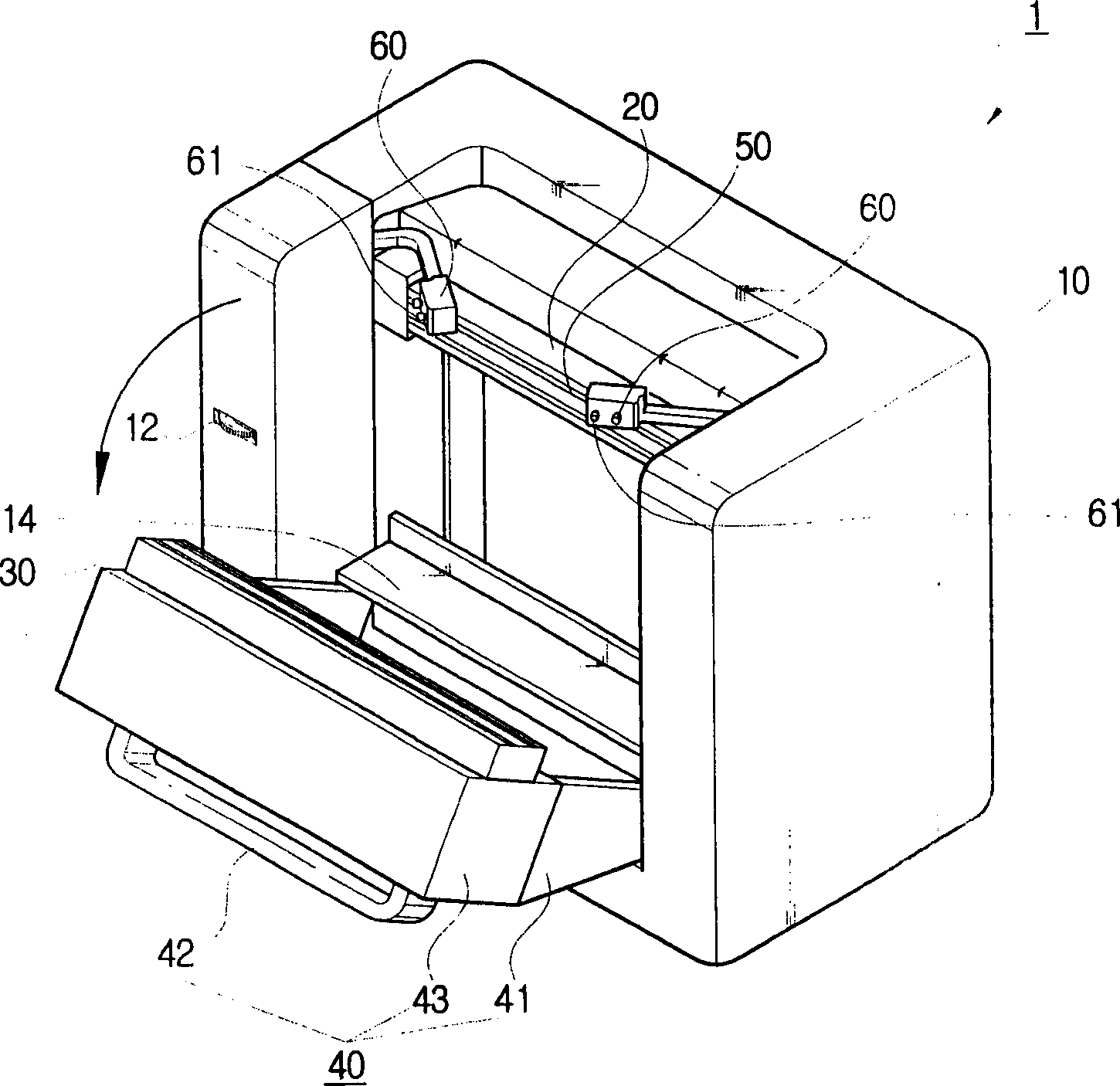

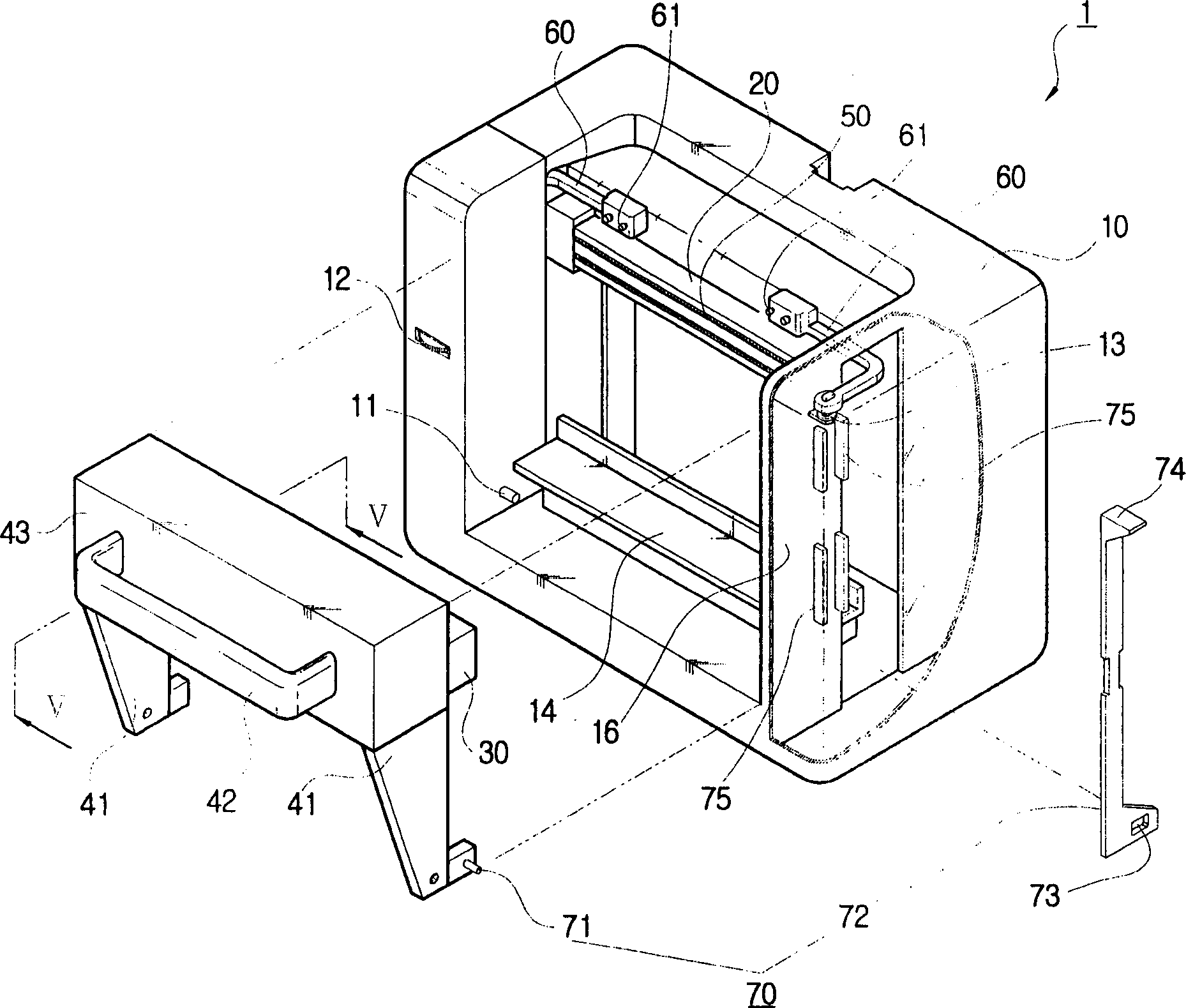

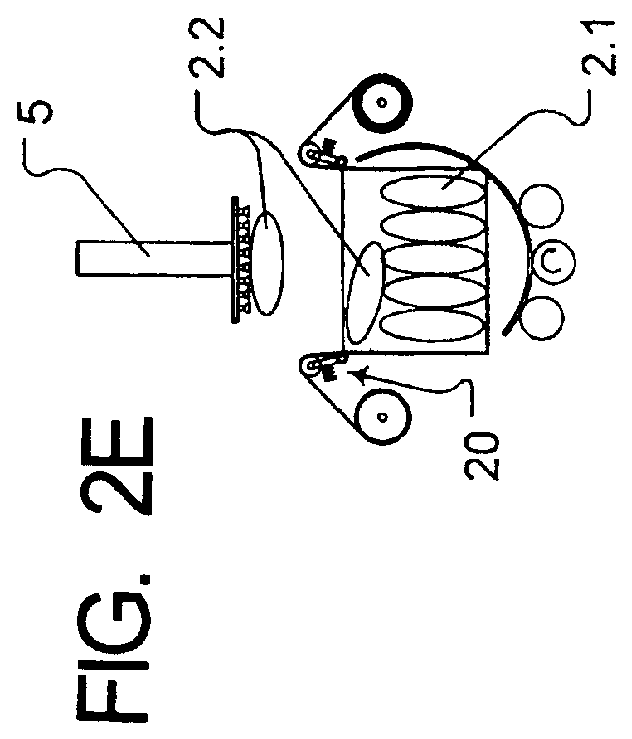

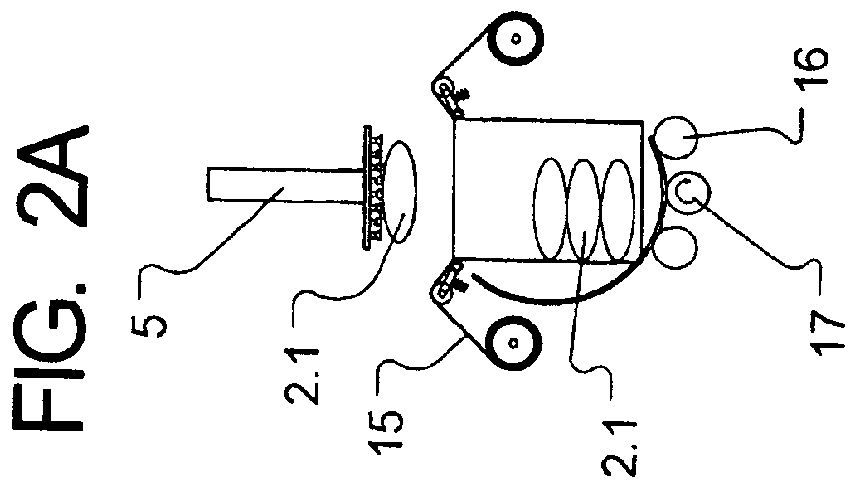

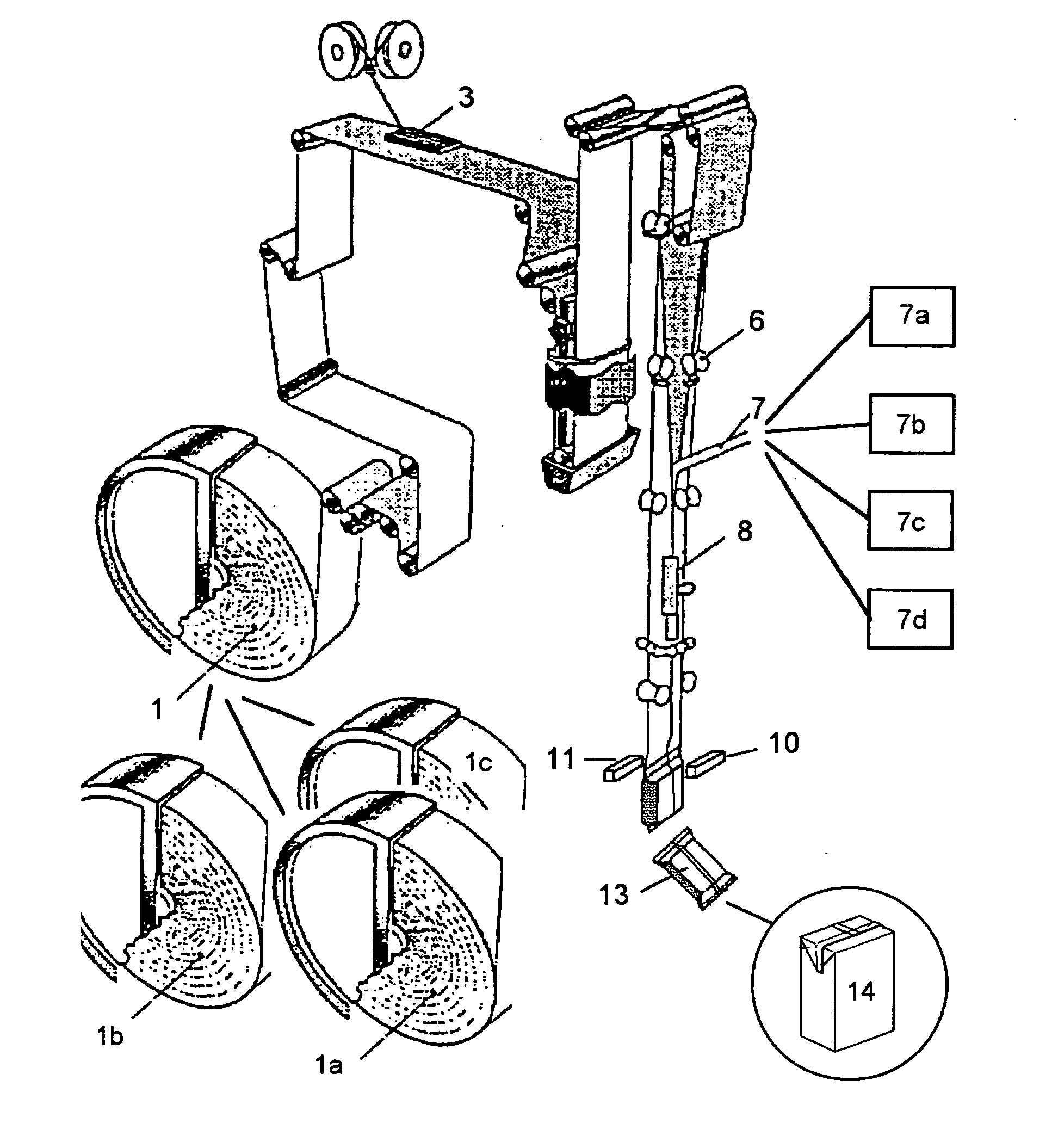

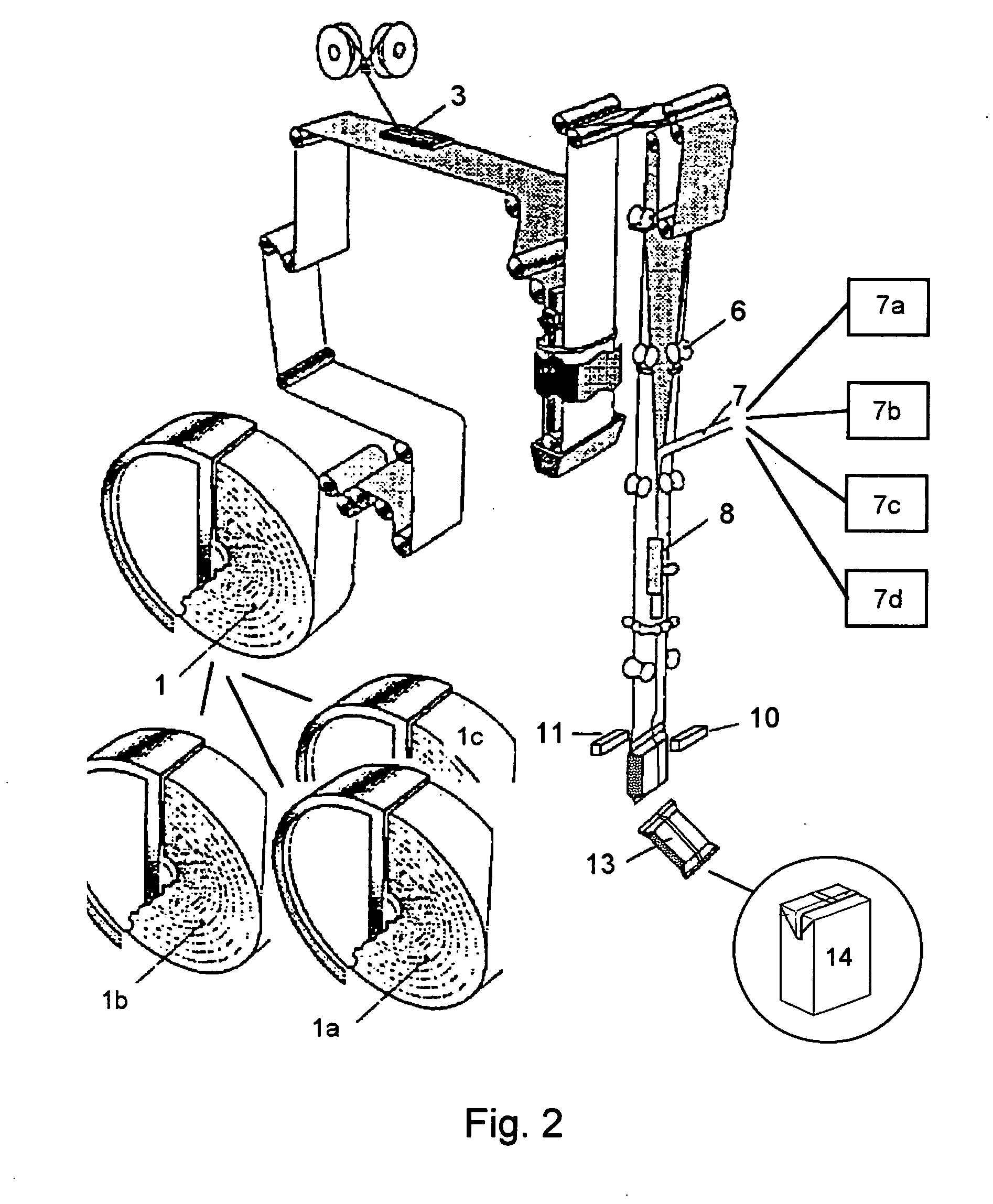

Packing filling machine and lateral sealing machine

InactiveUS20070017189A1Suitable sealing qualityReduces sealing check operationWrapper twisting/gatheringDomestic articlesAutomatic controlEffect factor

A packaging filling apparatus, which can obtain the most suitable sealing quality by an automatic control without checking the condition of sealing by the operator on a regular basis, is provided. A transversal sealing apparatus 48 of the packaging filling apparatus includes a high-frequency oscillator 1, controller 2, and an inductor, which generates a magnetic field in said packaging material by receiving the output from the high-frequency oscillator, and is provided with a sealing quality control means 4, which transmits a control signal to the controller, based on a statistical relation between a plurality of effect factors affecting the quality of said transversal sealing 23 and the quality of said transversal sealing.

Owner:TETRA LAVAL HLDG & FINANCE SA

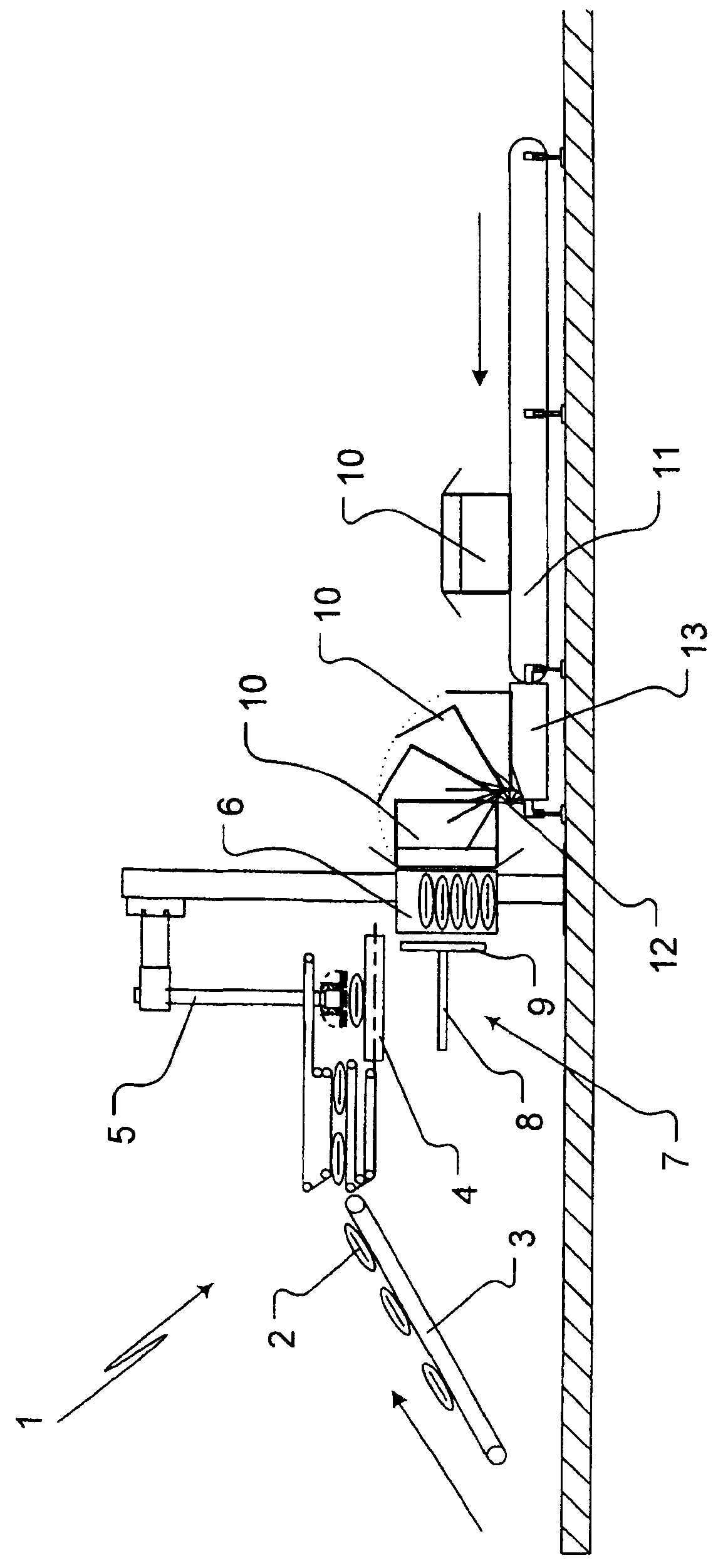

Beverage bottling plant for filling beverage bottles with a liquid beverage material with packing apparatus for packing filled bottles and a method of operation thereof

InactiveUS20070169433A1Improve stack stabilityImprove stabilityWrappers shrinkageWrapping material feeding apparatusTrademarkEngineering

A beverage bottling plant for filling beverage bottles with a liquid beverage material with packing apparatus for packing filled bottles and a method of operation thereof. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS MASCHEN UND ANALAGENBAU AKTIENGES

Packaging filling apparatus and transversal sealing apparatus

InactiveUS7484347B2Suitable sealing qualityReduces sealing check operationWrapper twisting/gatheringDomestic articlesEffect factorAutomatic control

A packaging filling apparatus, which can obtain the most suitable sealing quality by an automatic control without checking the condition of the sealing by the operator on a regular basis, is provided. A transversal sealing apparatus 48 of the packaging filling apparatus includes a high-frequency oscillator 1, controller 2, and an inductor, which generates a magnet field in packaging material by receiving the output from the high-frequency oscillator, and is provided with a sealing quality control means 4, which transmits a control signal to the controller, based on a statistical relation between a plurality of effect factors affecting the quality of a transversal sealing 23 and the quality of transversal sealing.

Owner:TETRA LAVAL HLDG & FINANCE SA

Method for processing fish of red flesh

InactiveUS20050048188A1Same palatabilityFreeze fastMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsAmbient airMixed gas

A method for processing a fish of red flesh includes a packing step of cutting a fish in such a shape as would fit immediate use by consumers, piling the cut fish orderly on a tray and stowing the cut fish on the tray into a pack, a vacuumizing step of filling the pack during the packing step with a vacuum atmosphere, a gas-filling step of filling the pack immediately after completion of the vacuumizing step with a mixed gas of carbonic acid gas and oxygen gas without exposing the interior of the pack to the ambient air, thereby exposing the fish to the mixed gas, a pack-sealing step of tightly closing the pack filled with the carabonic acid and the oxygen gas, and a freezing step of quickly freezing the fish contained in the pack and transforming the fish into a frozen fish.

Owner:YOSHIO ARAI

Nano packing filling and method for making same

InactiveCN1699494AImprove sealingExtended service lifeOther chemical processesPack fillingMaterials science

Owner:张志伟

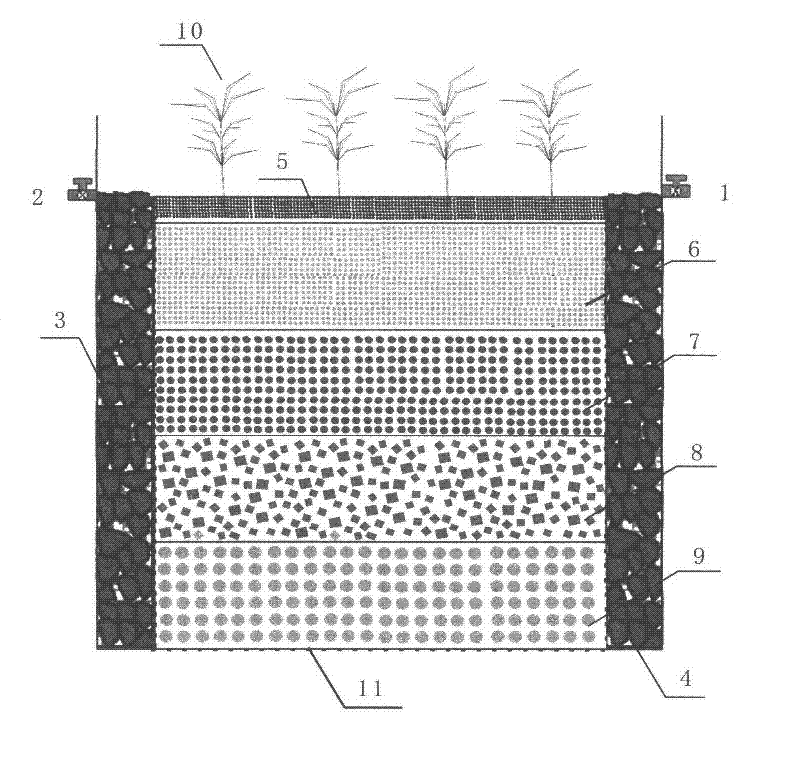

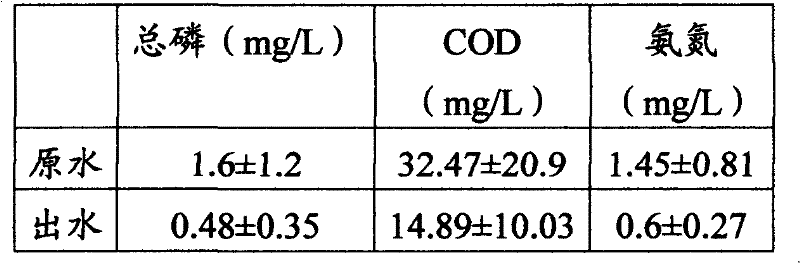

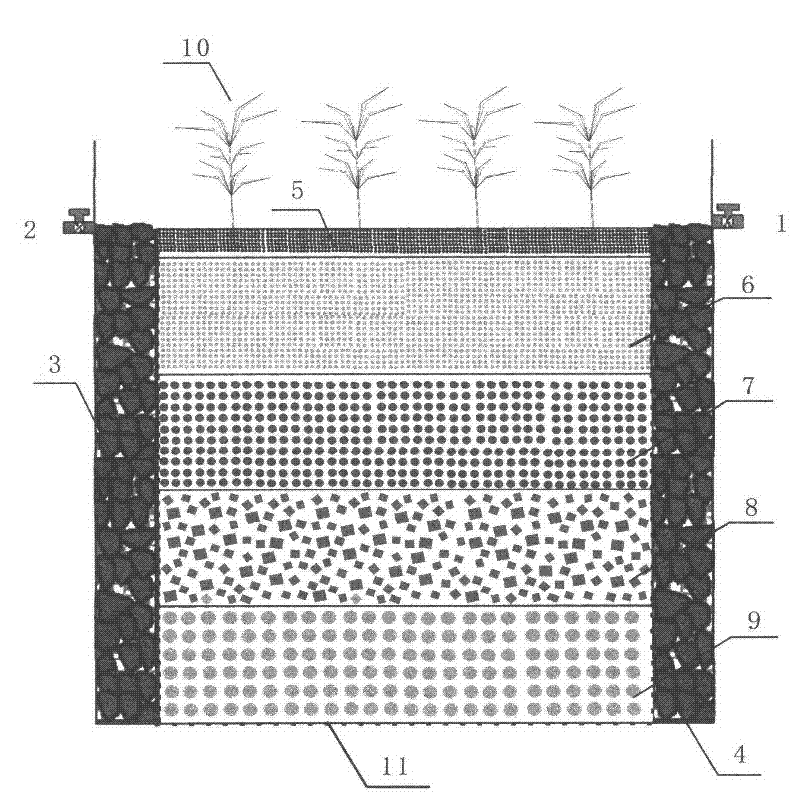

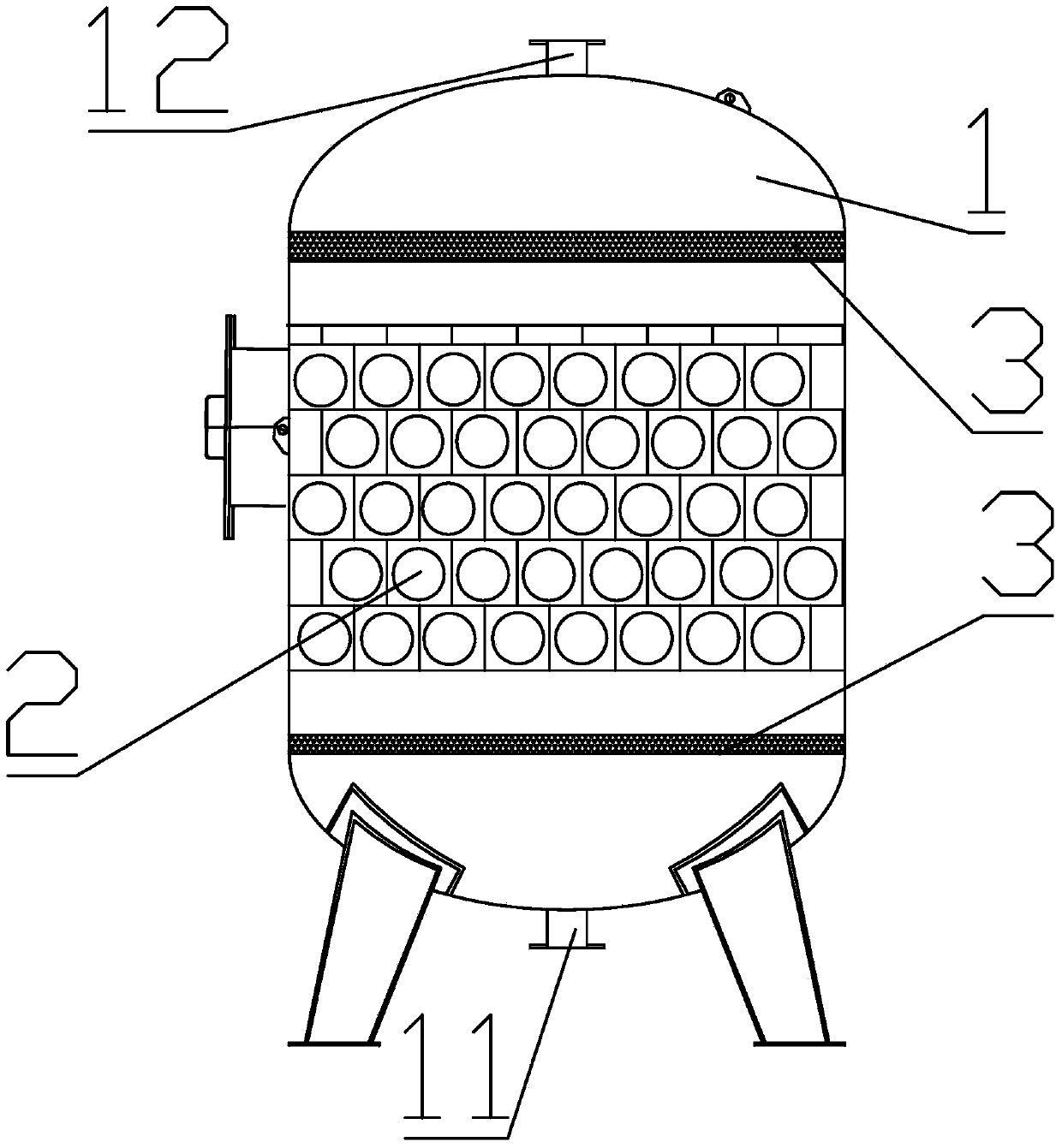

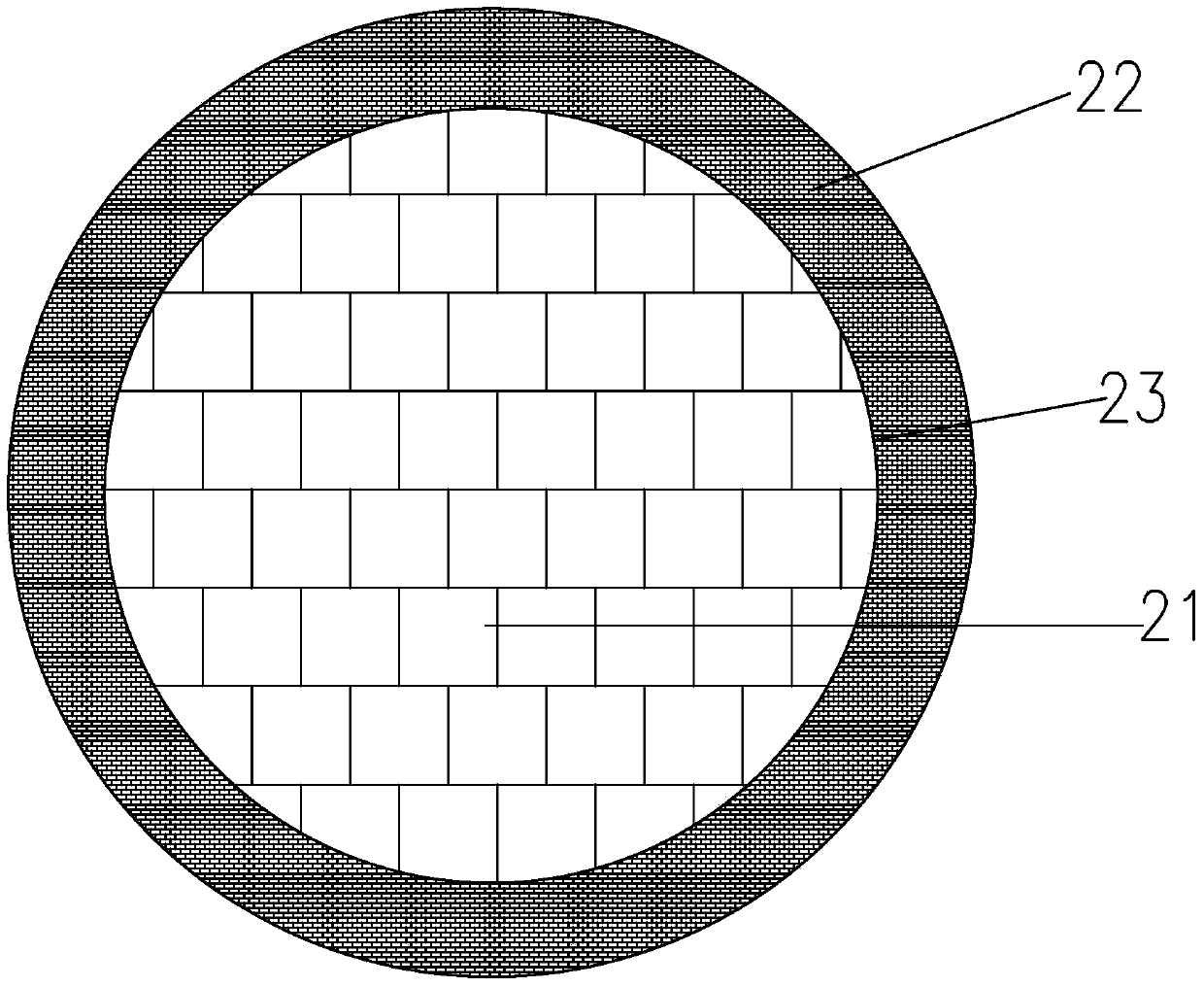

Water purifying method of uniform flow constructed wetland

ActiveCN102381767AAvoid formingFull play of physicsSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater flow

The invention discloses a water purifying method of a uniform flow constructed wetland. A constructed wetland is established; a water inlet end is arranged on one wall of the wetland pool, and a water outlet end is arranged on the other wall of the wetland pool; the water inlet end and the water outlet end are respectively provided with a water distributing zone and a water gathering ground, which are filled with cobblestones with a particle size of 30-50mm; a main body filling material zone comprises, from top to bottom: a first layer filter pack filled with a quartz sand filling material with a particle size of 0.1-1 mm, a second layer filter pack filled with a quartz sand filling material with a particle size of 0.1-3mm; a third layer filter pack filled with a quartz sand filling material with a particle size of 1-3 mm; a fourth layer filter pack filled with a quartz sand filling material with a particle size of 1-5 mm; a fifth layer filter pack filled with a quartz sand filling material with a particle size of 3-7 mm; and humidogene emergent aquatic plant plants are planted on top of the first layer filter pack. The invention can be used in treatment of household sewage in cities and towns and industrial wastewater of food processing industry and slaughter industry, etc., so as to avoid current short flow and formation of a dead zone and remove pollutants efficiently.

Owner:恒晟水环境治理股份有限公司

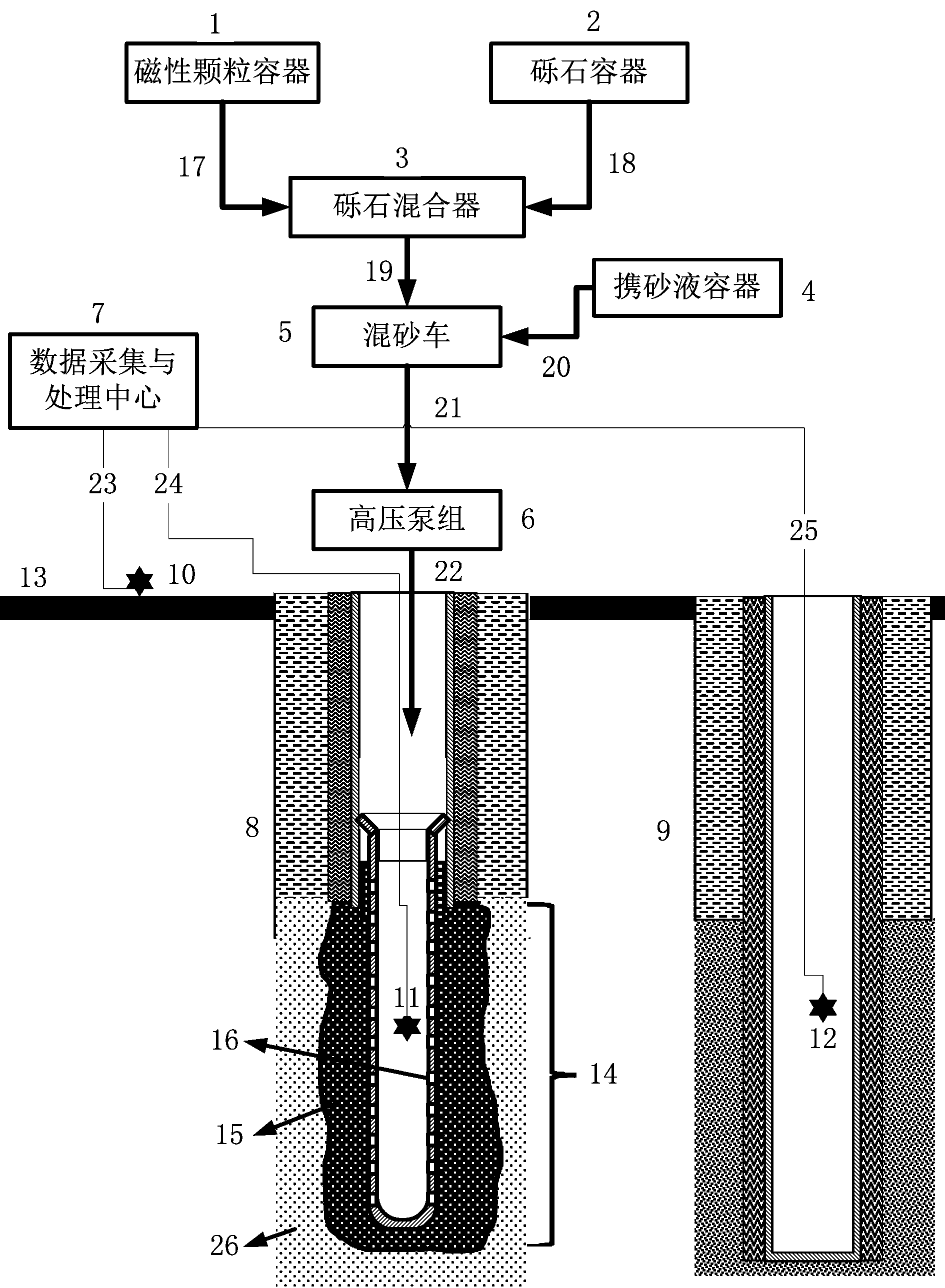

Gravel pack filling monitoring system and monitoring method based on magnetic media

The invention relates to a gravel pack filling monitoring system and method. The gravel pack filling monitoring system comprises a magnetic particle container, a gravel pack container, a gravel pack mixer, a sand-carrying fluid container, a sand mixing truck, a high-pressure pumping set, a data acquisition and processing center, a ground magnetometer, a magnetic particle conveying pipeline, a gravel pack conveying pipeline, a evenly-mixing gravel pack conveying pipeline, a sand-carrying fluid conveying pipeline, a first sand-mixing fluid conveying pipeline, a second sand-mixing fluid conveying pipeline and a ground magnetometer and data acquisition and processing center communication pipeline, wherein the ground magnetometer monitors magnetic parameter changing from the ground, the data acquisition and processing center is connected with the data acquisition and processing center communication pipeline through the ground magnetometer, and the data acquisition and processing center collects and stores the measured information of the ground magnetometer and calculates and displays the gravel pack distribution state. The gravel pack filling monitoring system can track the transporting and distributing state of gravel pack in a sand-prevention well section from the ground, the well and / or an adjacent well during gravel pack filling and can achieve repeated detection on gravel pack distribution after production of the sand-prevention well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method of manufacturing and stacking packaging units with increased stability

InactiveUS7574843B2Improve stack stabilityPrevents or essentially prevents the lateral slippage of the individual packaging unitsWrappers shrinkageLiquid materialProcess engineeringBottle

A beverage bottling plant for filling beverage bottles with a liquid beverage material with a packing apparatus for packing filled bottles and a method of operation thereof. Further, a method of manufacturing and stacking packaging units with increased stability is performed.

Owner:KHS MASCHEN UND ANALAGENBAU AKTIENGES

Magnetorheological medical brace

ActiveUS20130023720A1Increase and decreases stiffnessElectrotherapyMagnetotherapy using coils/electromagnetsMagnetorheological fluidUltimate tensile strength

The magnetorheological (MAR) medical brace includes a flexible outer shell that fits around the anatomical area to be braced and a plurality of adjustable straps for securing the shell onto the anatomical area. The shell encases a MAR pack filled with magnetorheological fluid or gel. A plurality of magnets is attached to or encased in the shell to provide a magnetic field acting on the MAR pack. The interaction of the magnetic field with the MAR pack adjustably increases or decreases the stiffness of the shell depending on the strength of the magnetic field, A control mechanism is provided for selective adjustment of the magnetic field and other functions.

Owner:SOLOMON CLIFFORD T +1

Silicon carbide synthesis method

The invention discloses a silicon carbide synthesis method. The silicon carbide synthesis method includes procedures of filling packing, electrifying and heating, keeping constant power, naturally cooling and discharging. The silicon carbide synthesis method is characterized in that at least a graphite slurry layer is smeared on a burner graphite electrode on one side of a furnace heating cavity before conduction graphite powder is filled in the packing filling procedure, and then packing filling procedure for the conduction graphite powder is carried out. Compared with the prior art, the silicon carbide synthesis method has the advantages that melt can be prevented from being adhered on the surface of the graphite electrode, the surface of the graphite electrode can be cleaned quite easily before next loading, graphite powder and the melt which are smeared on the surface of the graphite electrode can be completely removed only by means of lightly scraping the surface of the graphite electrode by the aid of a scraper, further, water is used as a bonding agent during smearing and volatilizes when heated, conductivity between the graphite electrode and the graphite powder of a furnace core is unaffected, the surface of the graphite electrode cannot be damaged, accordingly, the service life of the graphite electrode is greatly prolonged, maintenance frequency is reduced, production efficiency is improved, and production cost is lowered.

Owner:石河子市丰拓硅材料科技有限公司

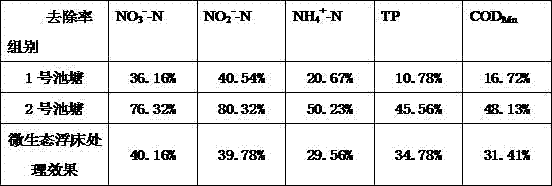

Microecological floating bed for purifying Aquaculture water body and application method of microecological floating bed

ActiveCN106976985AHang film fastImprove the efficiency of birthWaste water treatment from animal husbandrySustainable biological treatmentMicroorganismSewage

The invention discloses a microecological floating bed for purifying an aquaculture water body and an application method of the microecological floating bed. The microecological floating bed comprises one or more freely combined microecological floating bed unit, wherein the microecological floating bed unit mainly comprises an inflatable floating bed, microecological particles and aquatic plants; more than one planting hole is uniformly formed in the inflatable floating bed and the bottom of each planting hole is hollowed out; packing filled in the planting holes is the microecological particles; and the aquatic plants are planted on the microecological particles. More than one microecological floating bed unit is selected according to the area of a to-be-purified water body to be quickly linked and freely combined through a coupling ring in use, the microecological floating bed is fixed on a pile by using a rope, and the microecological floating bed is fixed on the water level. Aquaculture wastewater can be efficiently and quickly treated by using the synergistic effect between the aquatic plants and microorganisms.

Owner:HOHAI UNIV

Tea packaging machine

ActiveCN105691660AEfficient weighing and feedingImprove packaging efficiencySolid materialProduction lineControl system

The invention discloses a tea packaging machine which comprises an automatic feeding device, an overturning type clamping claw mechanism, an inner-bag-available packaging filling and switching mechanism, an inner-bag-free packaging filling and switching mechanism, a control system and other necessary components of the tea packaging machine. The automatic feeding device is arranged at the feeding position of the tea packaging machine, and cooperative work of all the components is controlled through the control system. A left vibration feeding plate and a right vibration feeding plate are weighed, then gathered discharging is conducted, and the packaging efficiency is improved on the premise that quantitative supplying is achieved. Due to the design of the overturning type clamping claw mechanism, inner bags containing tea particles can be accurately and reliably transferred into the inner bag filling mechanism, and the working stability of the tea packaging machine is effectively improved. An inner-bag-available packaging manner and an inner-bag-free packaging manner are provided for one tea packaging machine, the input cost of equipment in a tea packaging production line is reduced, and the utilization efficiency and the economic benefits of the equipment are improved.

Owner:张完郎

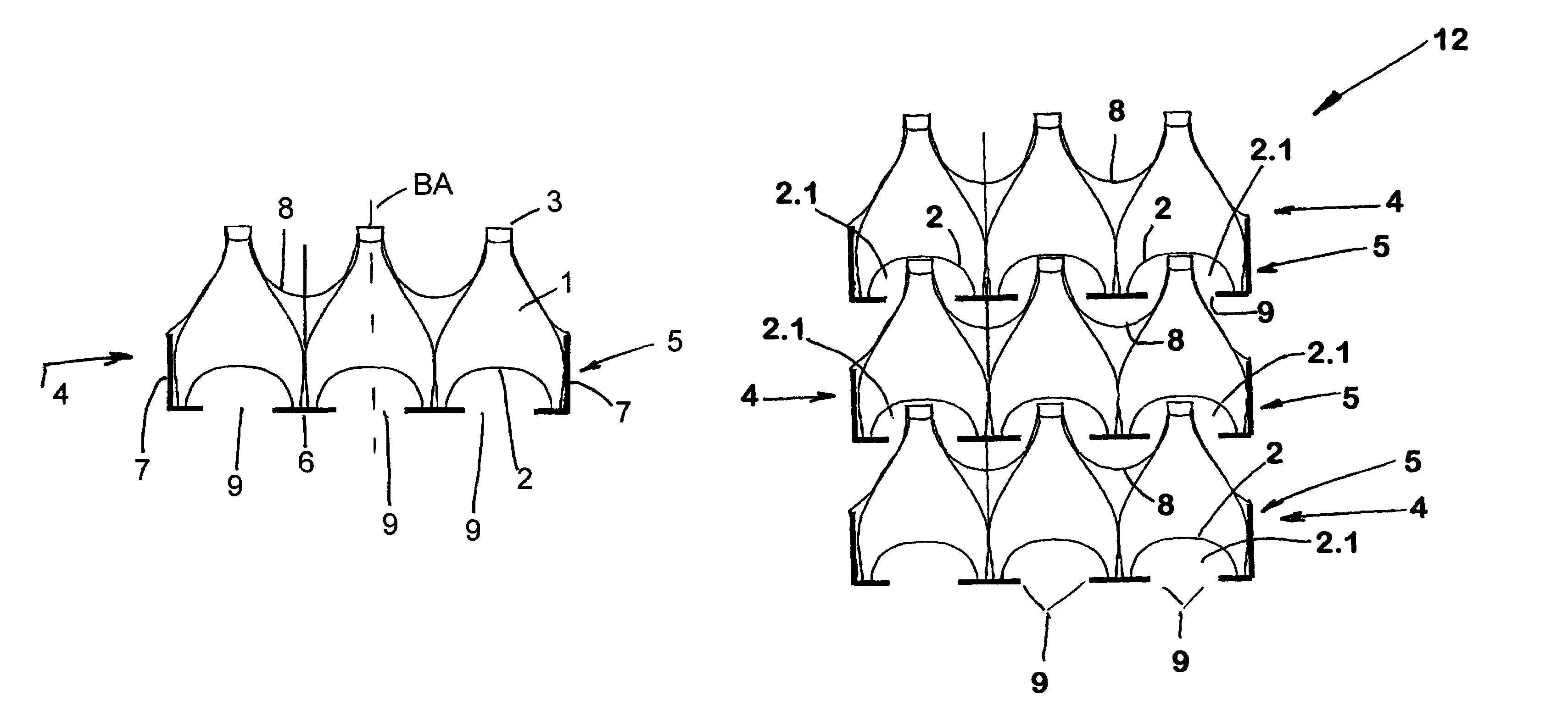

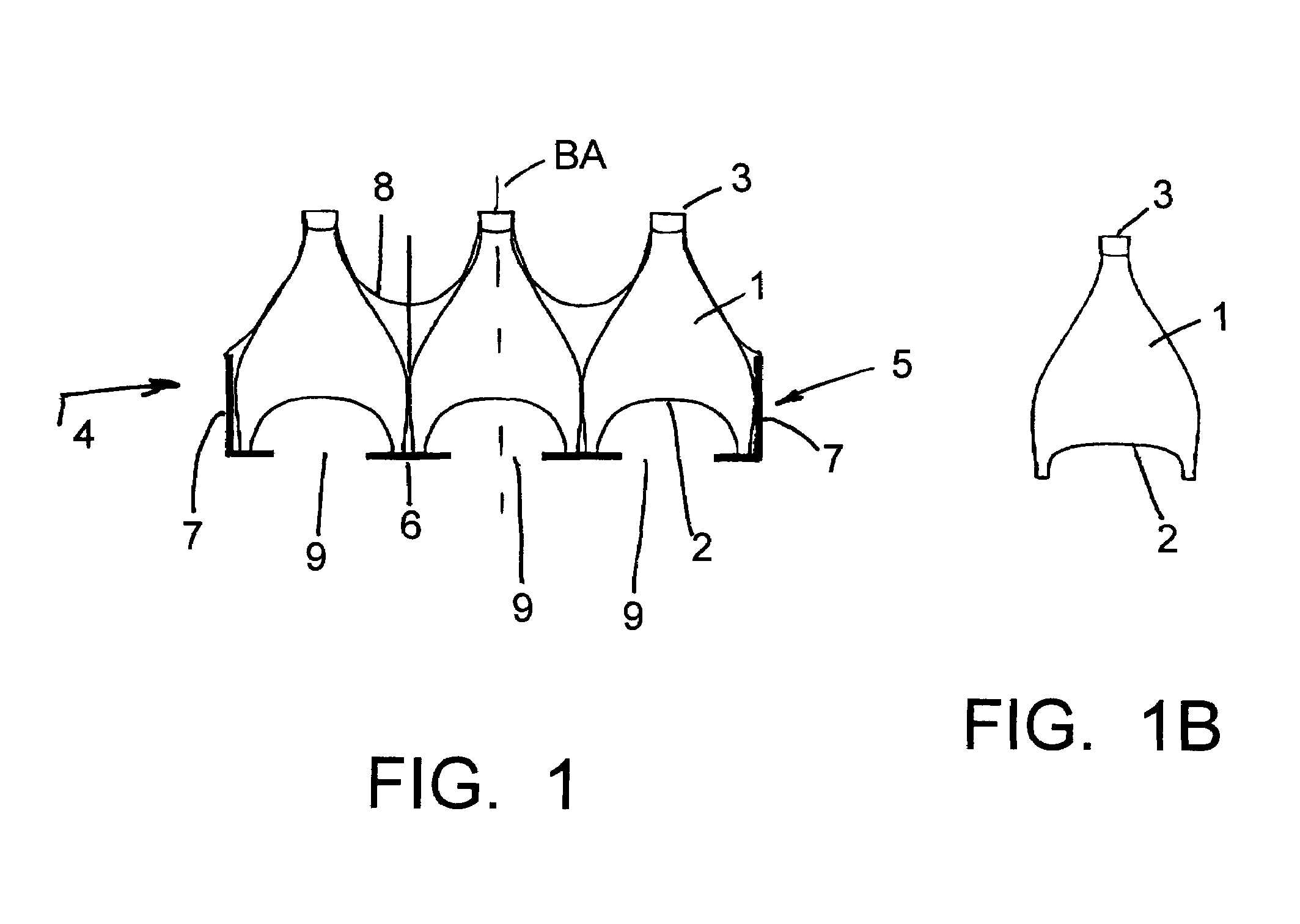

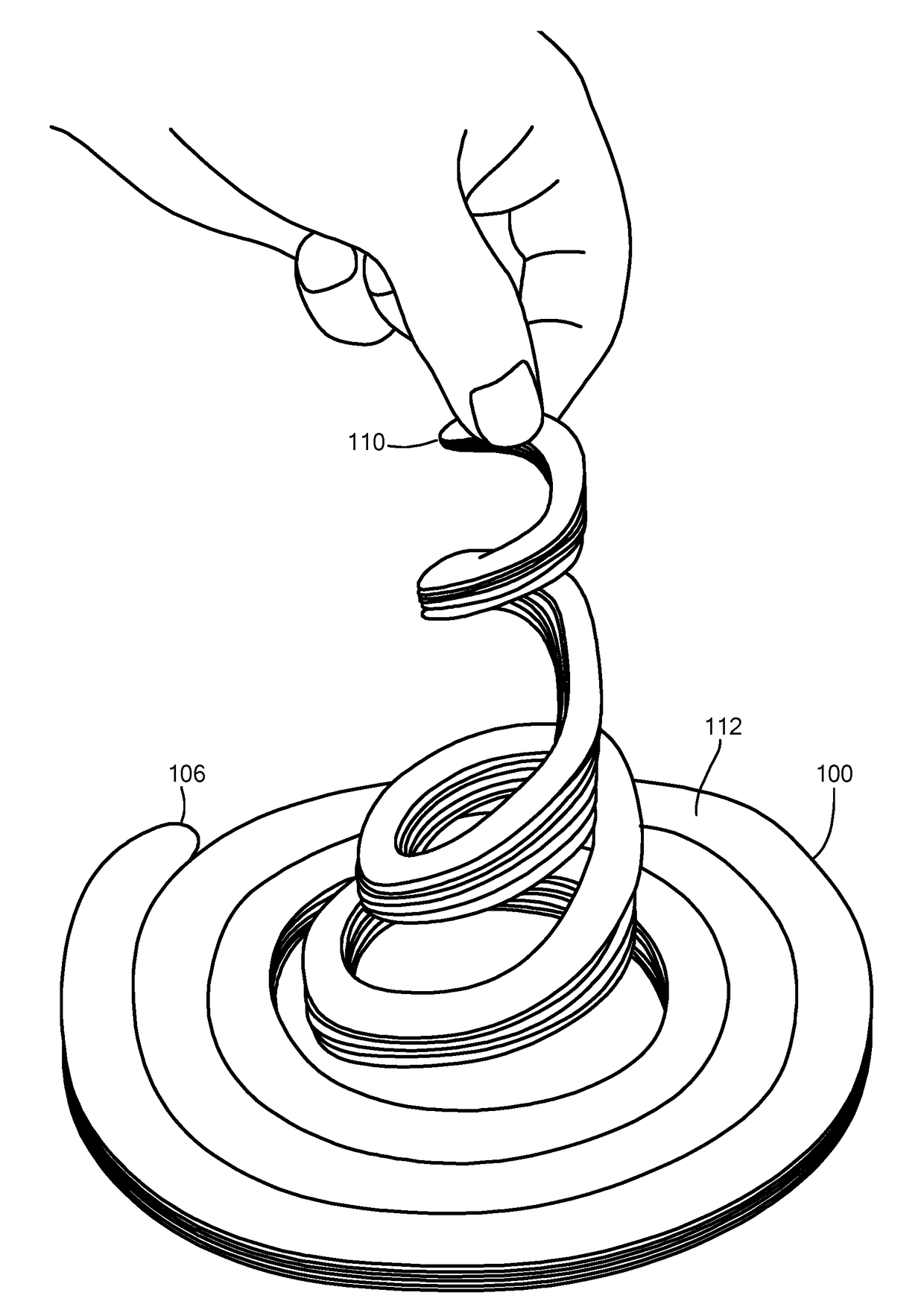

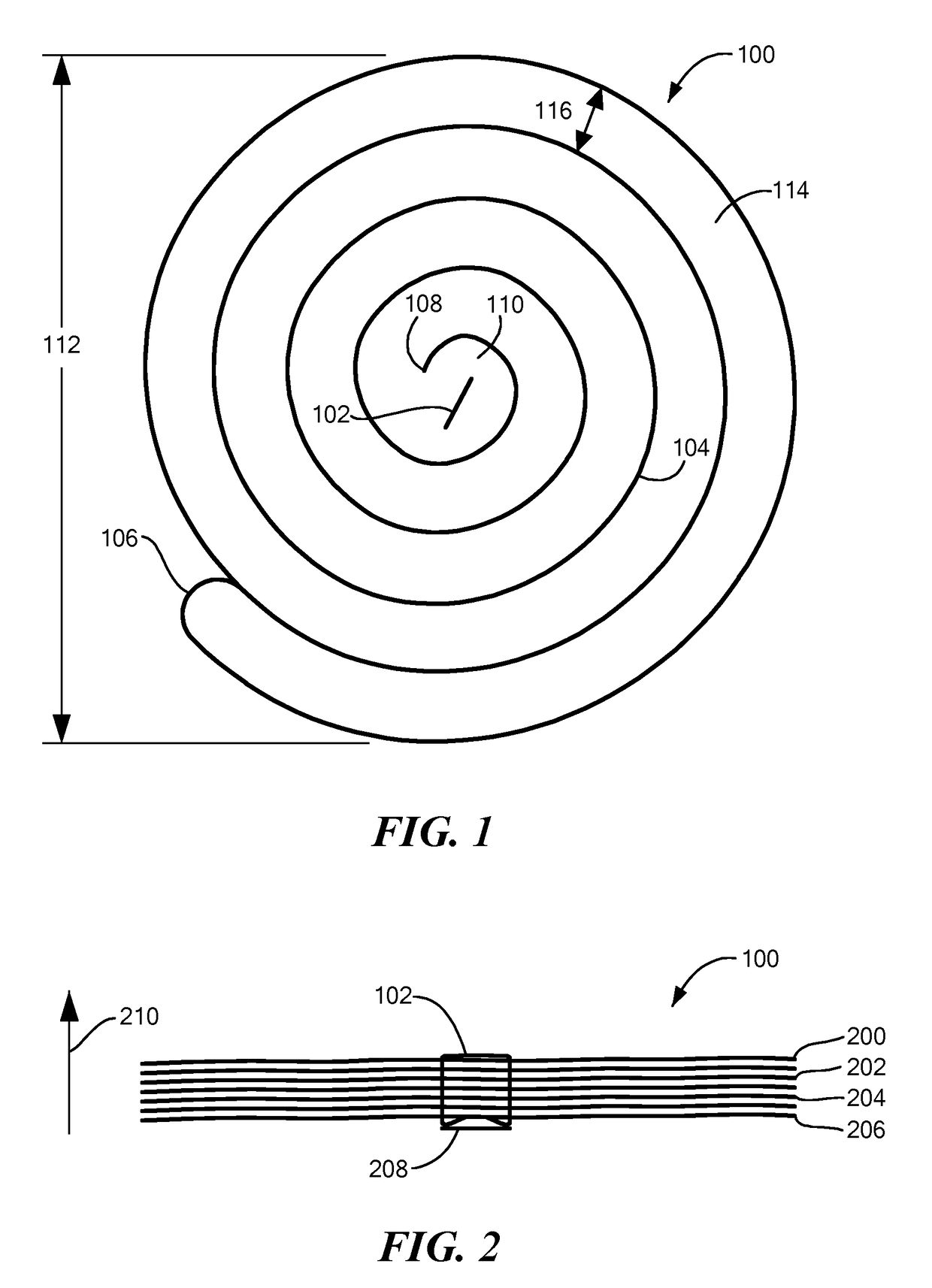

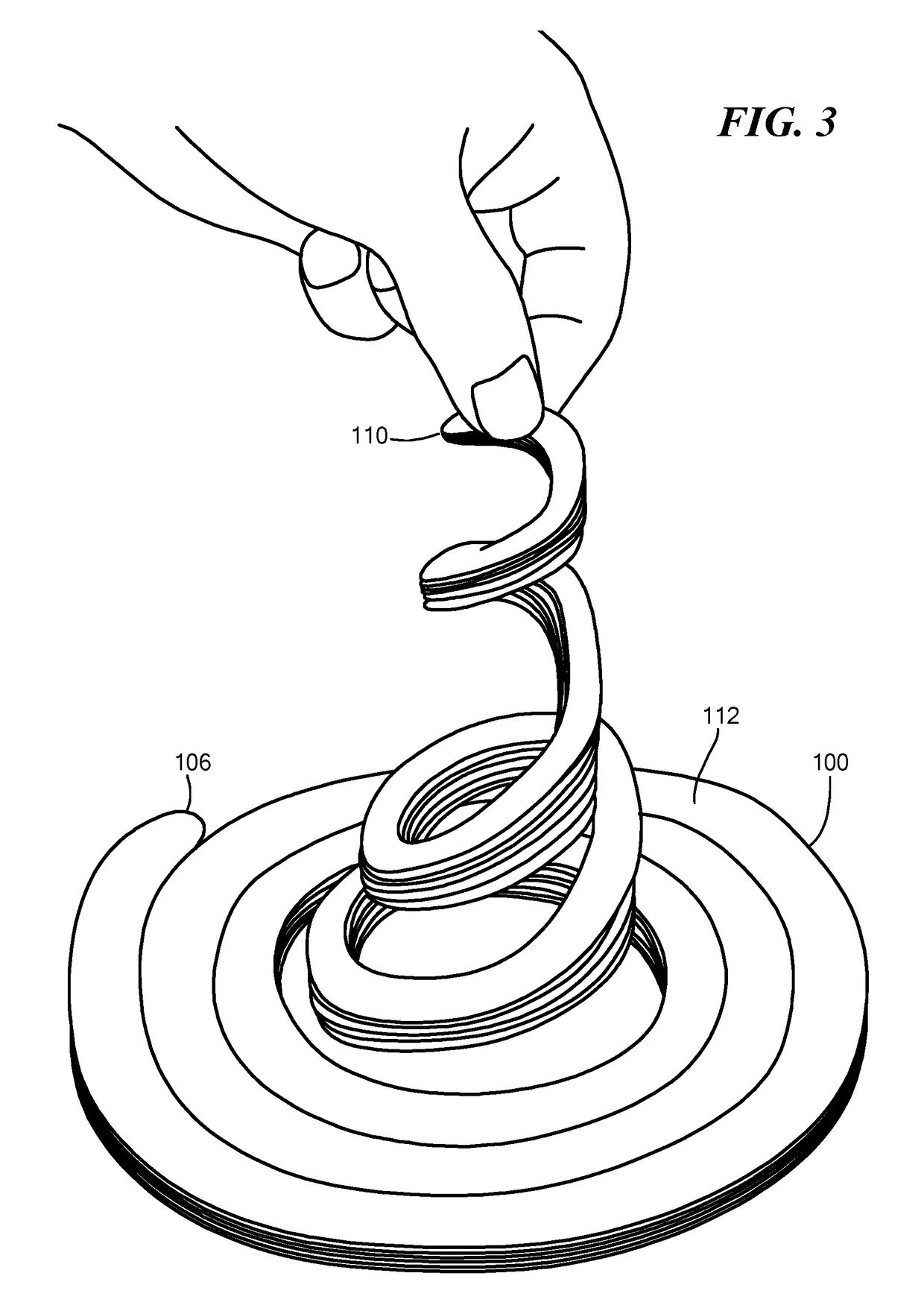

Expandable Package Filler or Ornament

ActiveUS20170267018A1Small volumePaper/cardboard articlesOrnamental textile articlesEngineeringTissue paper

An expandable package filler or ornament includes a stack of sheets, such as tissue paper, foil, etc. The stack is bound together, such as by a fastener. A generally spiral cut extends from a peripheral edge of the stack toward the center of the each sheet. The cut forms each sheet into a generally spiral strip ending in a peninsula portion. Grasping the peninsula portion, lifting and shaking the stack causes the strips to fall and entangle with each other. The resulting structure is decorative and may be used to stuff a gift box, bag or basket.

Owner:TEPE TED +1

Sealing machine

A sealing machine for sealing a pack filled with one or more objects, including a main case; a first sealing member provided in the main case; a second sealing member facing the first sealing member; a movable supporting part supporting the second sealing member and allowing the second sealing member to move near to, and away from, the first sealing member; and a heater provided in at least one of the first sealing member and the second sealing member to heat and melt the pack interposed therebetween.

Owner:SAMSUNG ELECTRONICS CO LTD

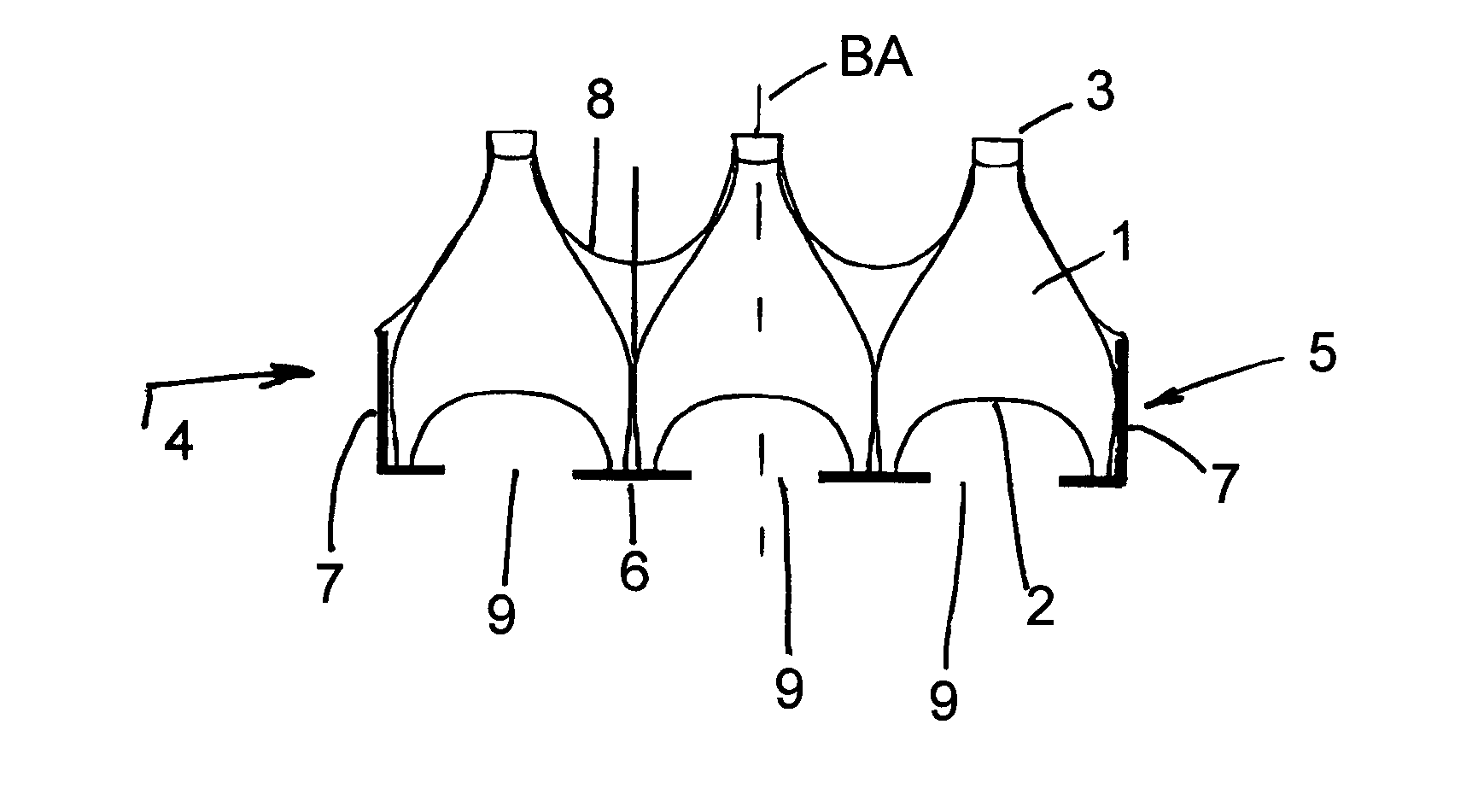

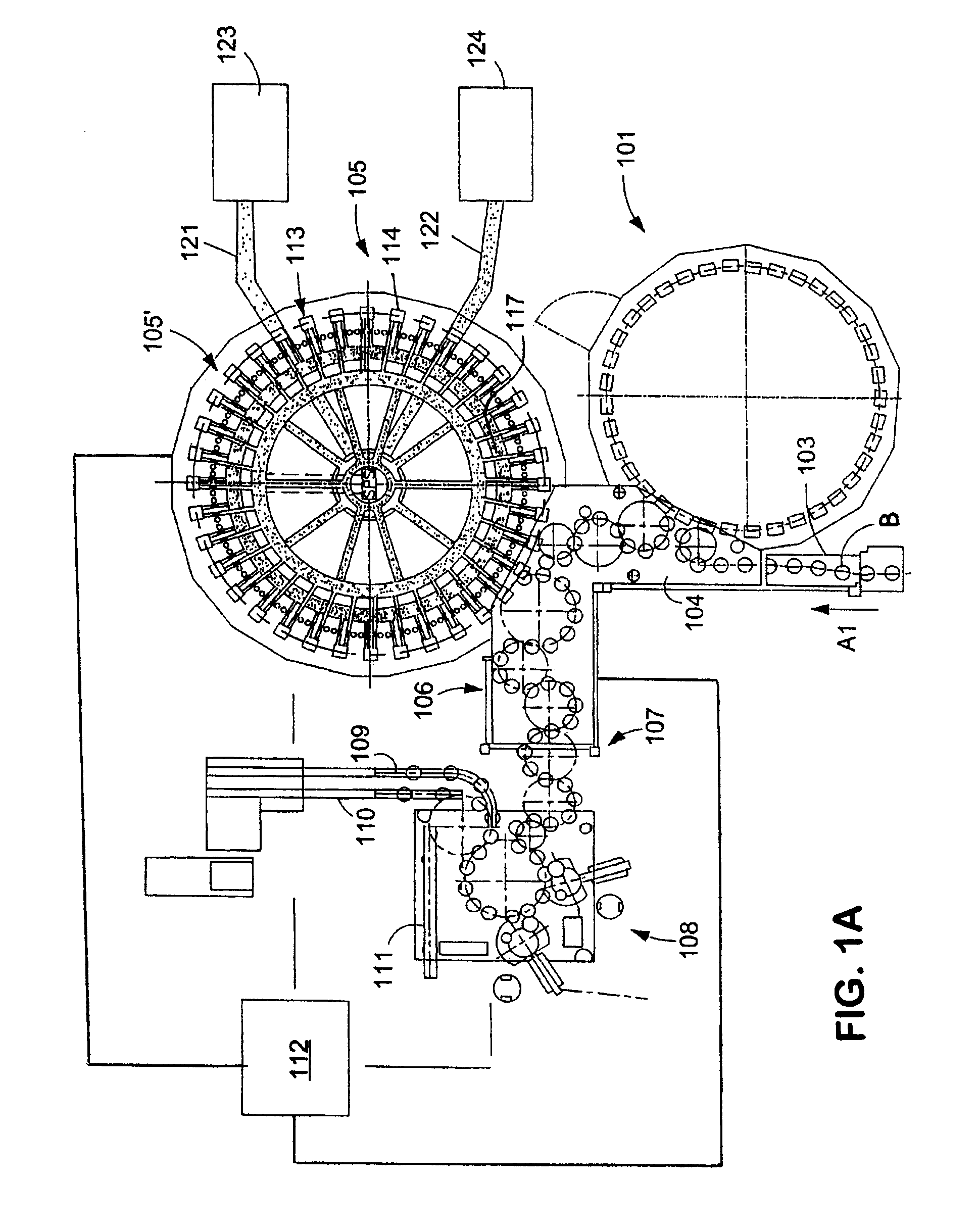

Package filling plant, a packing device and method for grouping a packing formation of packages and containers, and a packing device and method for grouping a packing formation of packages and containers

ActiveUS9334070B2Broad possible spectrumMinimize the possibilitySolid materialLiquid materialPack fillingEngineering

A packaging arrangement for packaging packages and a method of packaging packages using a packaging arrangement, in which the packages are moved into a receptacle supported on a flexible band. The band is moved to rotate the receptacle to allow at least one additional package to be inserted into the receptacle through another side.

Owner:KHS GMBH

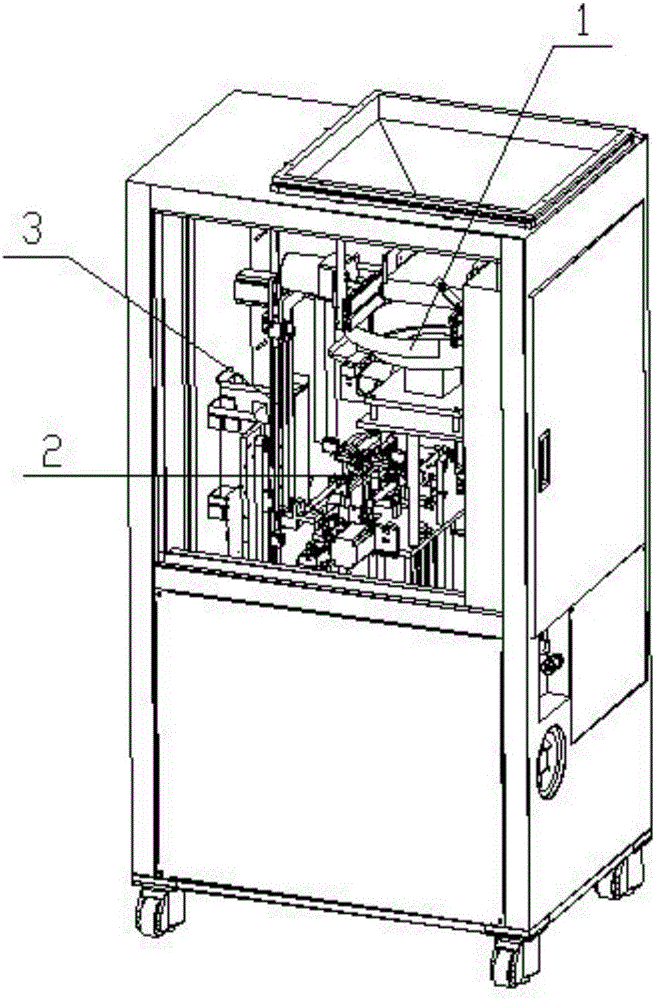

High-concentration ammonia-nitrogen wastewater treatment device

InactiveCN103755029AImprove processing efficiencyReduce energy consumptionTreatment with aerobic and anaerobic processesHigh concentrationTreatment effect

The invention provides a high-concentration ammonia-nitrogen wastewater treatment device. An ammonia-nitrogen pollution problem of a water body in our country is prominent increasingly at present. The device comprises a tank body, a water inlet pipe arranged at the bottom of the tank body, a water outlet pipe arranged at the top of the tank body, and packing filled in the tank body, wherein the packing is internally provided with anaerobic bacteria and externally provided with aerobic bacteria; and a plurality of slim holes are formed in the surface of the packing to communicate the interior with the exterior of the packing. With the implementation of the technical scheme, the device has the following technical effects that an ammonia-nitrogen removal rate of water quality reaches 99%, the treatment efficiency is high, the energy consumption is low, and the packing cannot be replaced for a long time, and is large in surface area, good in hydrophilicity, high in bioactivity, quick in membrane forming, good in treatment effect and long in service life.

Owner:浙江川宁环保科技有限公司

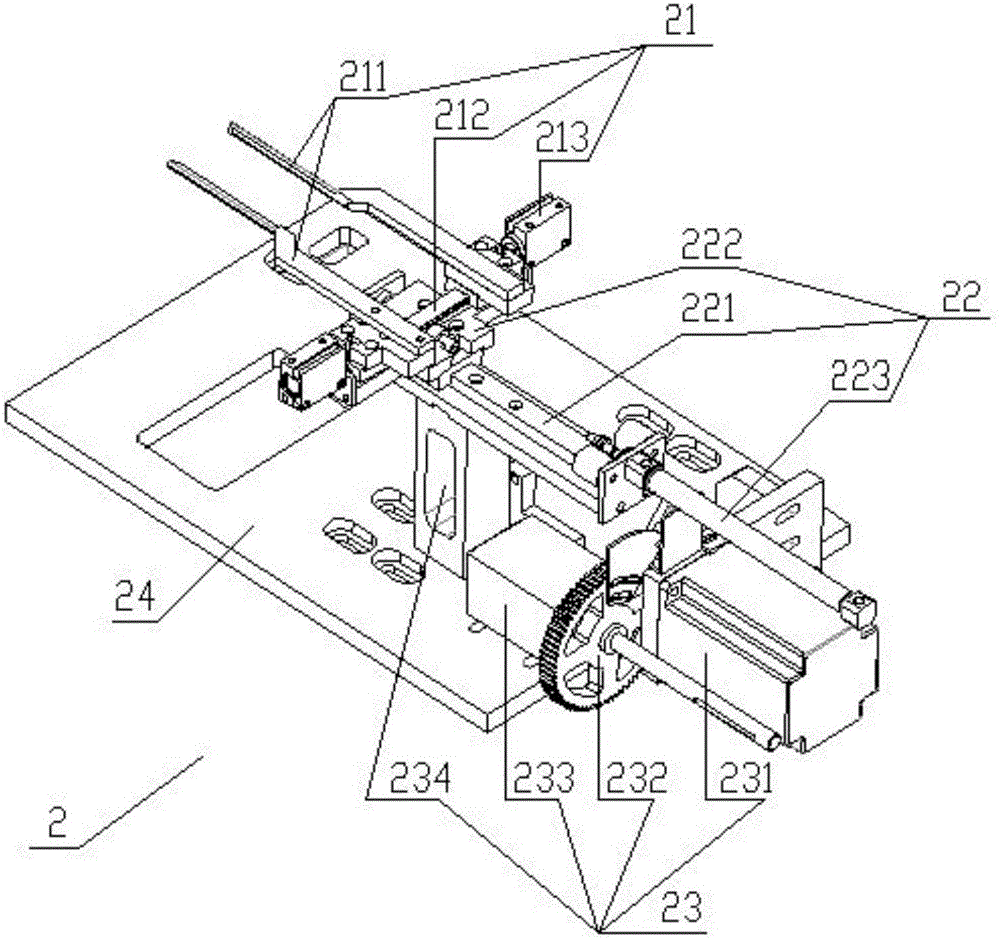

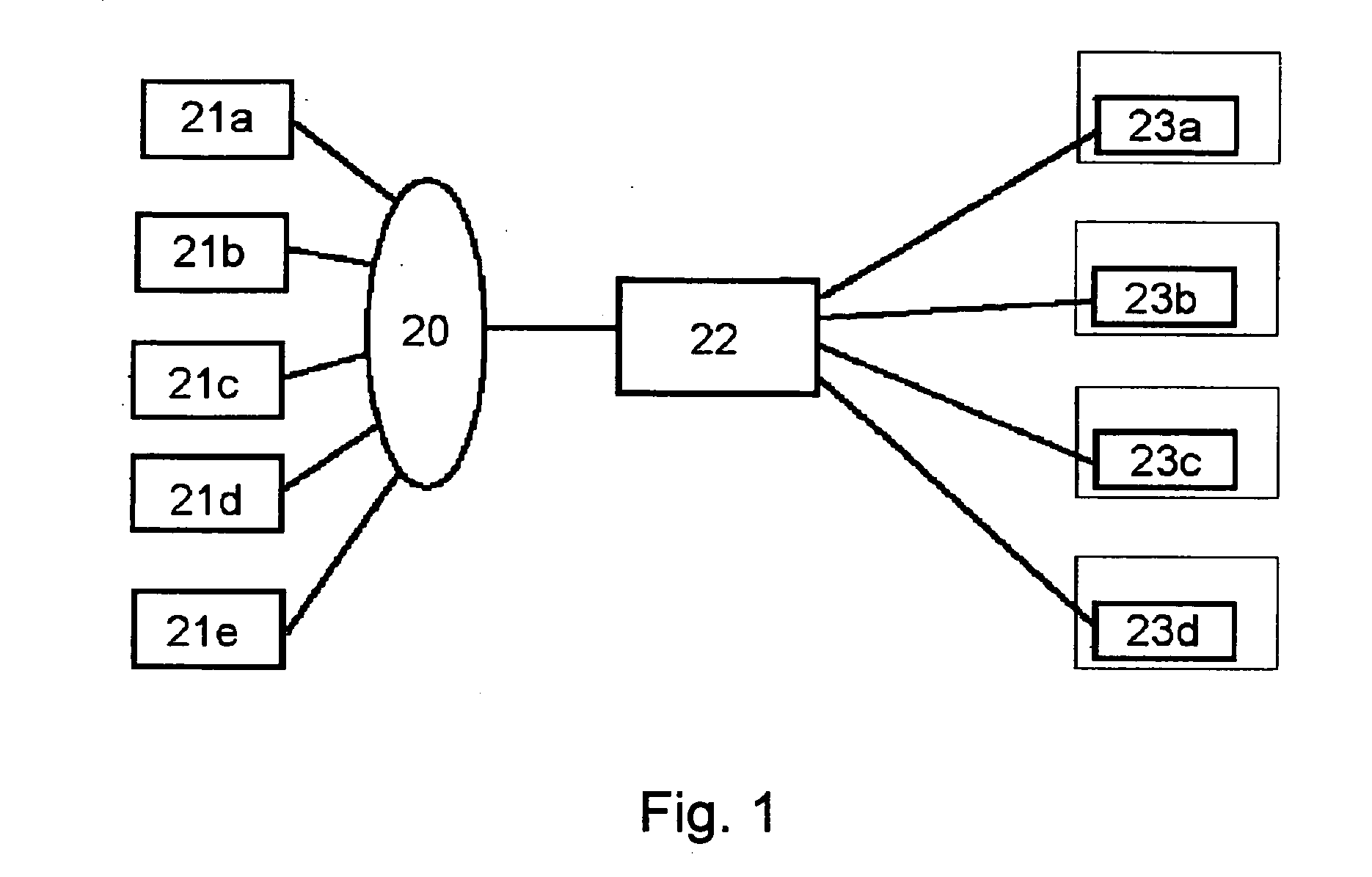

Wrapping/filling method, wrapping/filling device, commodity providing method, and commodity management method

InactiveUS20060074697A1Avoid difficult choicesFinancePackaging automatic controlApproaches of managementThe Internet

There is provided a wrapping / filling method that can be used by anybody anywhere for easily selecting a commodity content and commodity wrapping vessel and wrapping / filling the commodity content in a small scale including a test wrapping / filling. When a client requests wrapping / filling, a computer (21) of the client having a request condition is connected to a server computer (22) having a wrapping / filling condition database via the Internet (20). Wrapping / filling information appropriate for the request condition and the wrapping / filling condition of the client is obtained. According to the request from the client computer (21), wrapping / filling information is transmitted from the server computer (22) to a wrapping / filling device (23). A commodity content is filled by the wrapping / filling device (23) according to the wrapping / filling information and wrapped by a wrapping vessel according to the wrapping / filling information.

Owner:TETRA LAVAL HLDG & FINANCE SA

Nano packing filling and method for making same

InactiveCN100341972CImprove sealingExtended service lifeOther chemical processesPolymer sciencePolymer chemistry

Owner:张志伟

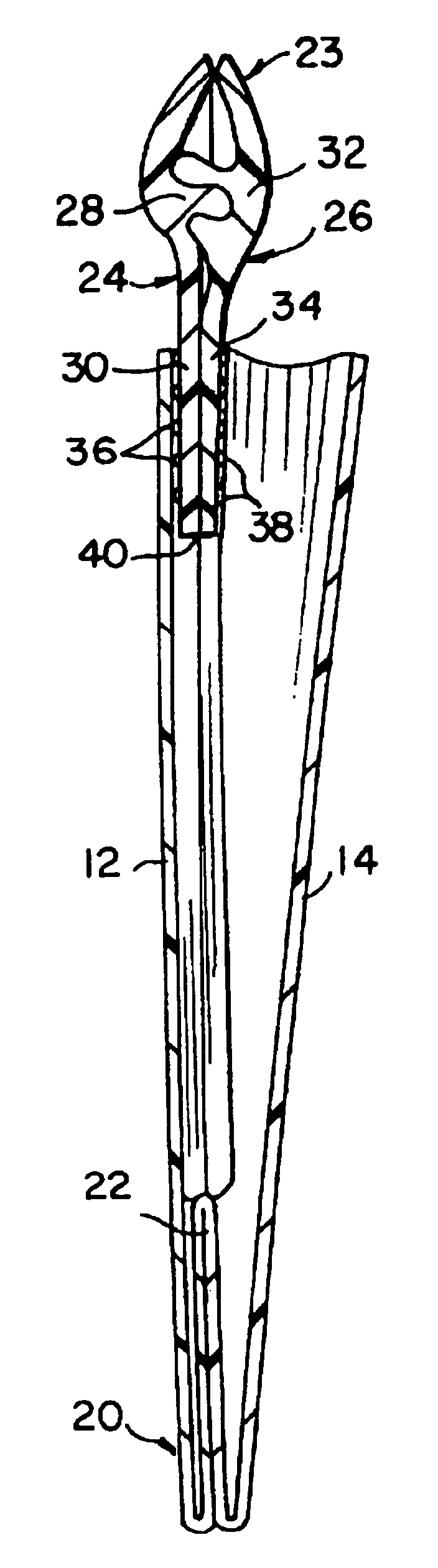

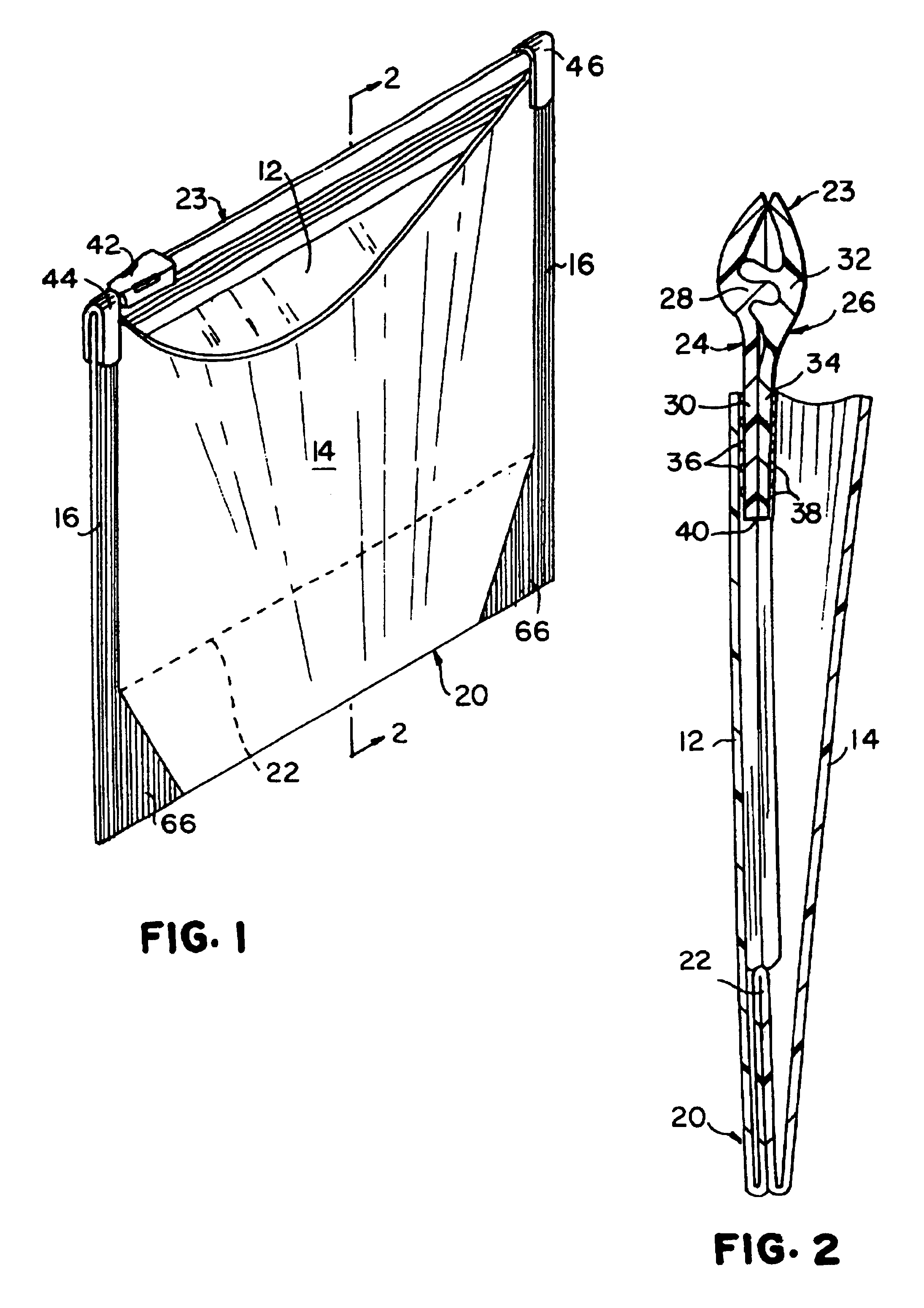

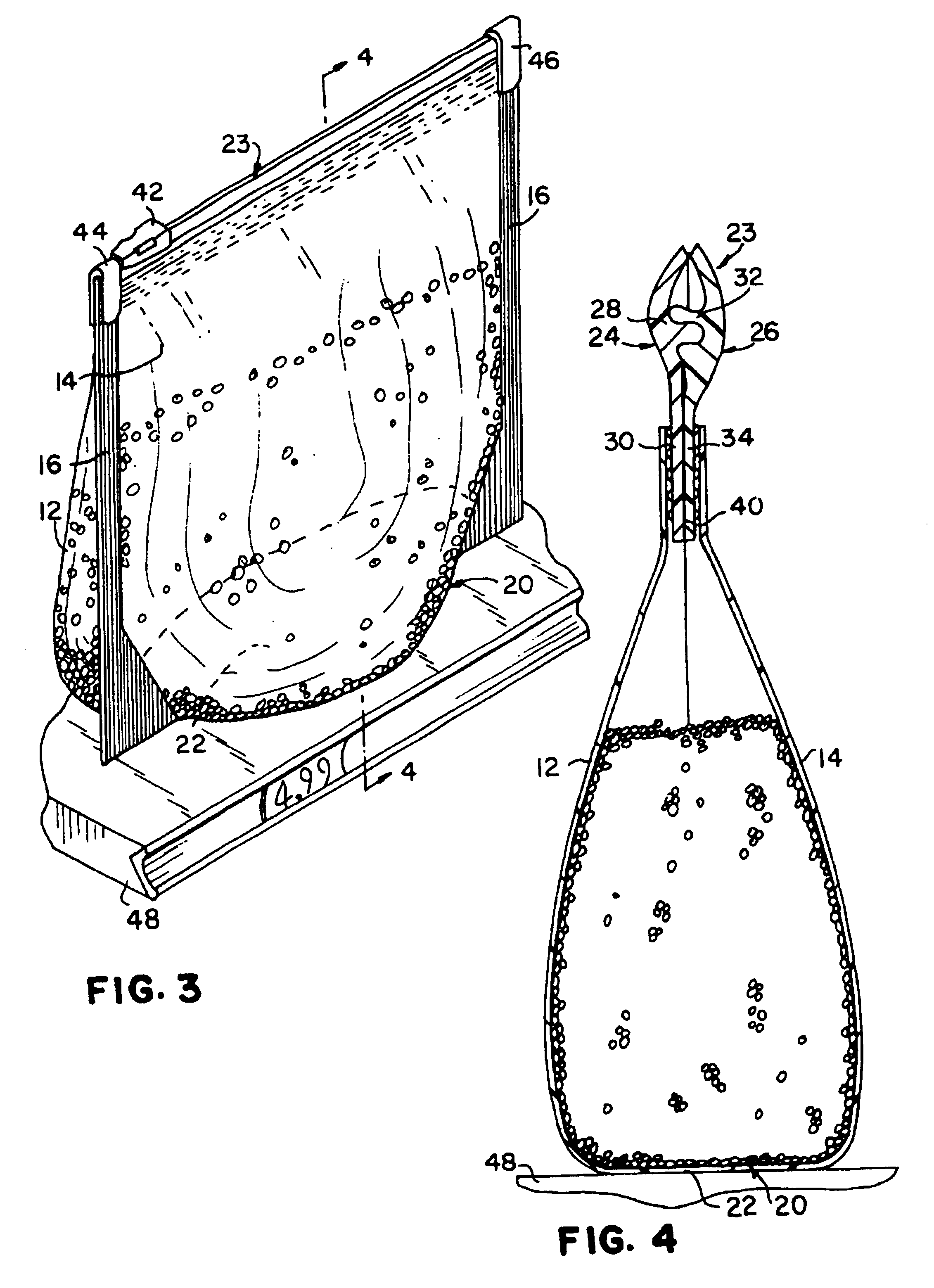

Supporting apparatus for flower arrangement

InactiveCN101156737AEasy to set upRopes and cables for vehicles/pulleyFlower preserving apparatusEngineeringMaterial Perforation

Owner:柳荣实

Top filled reclosable package with separate membrane and method for forming and filling the same

A method of forming and sealing a flexible, reclosable package having a zipper closure and a slider mounted thereon. The reclosable package is initially formed having a pair of opposing side panels and a zipper closure extending between the pair of side panels. The zipper closure is initially attached to the side panels only along a pair of spaced side seals. The reclosable package is filled with product through a fill opening created between the zipper closure and either one of the side panels. Once the package is filled with product, the attachment flanges of the zipper closure are sealed to both of the side panels. Thus, the zipper closure is sealed to the side panels only after product has been inserted into the product package.

Owner:REYNOLDS PRESTO PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com