Tea packaging machine

A technology for tea bags and packaging machines, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of slow weighing and feeding, affecting the efficiency of tea packaging, and complicated transfer mechanisms for inner bags, etc. Packaging efficiency, improving utilization efficiency and economic benefits, and stable and reliable work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

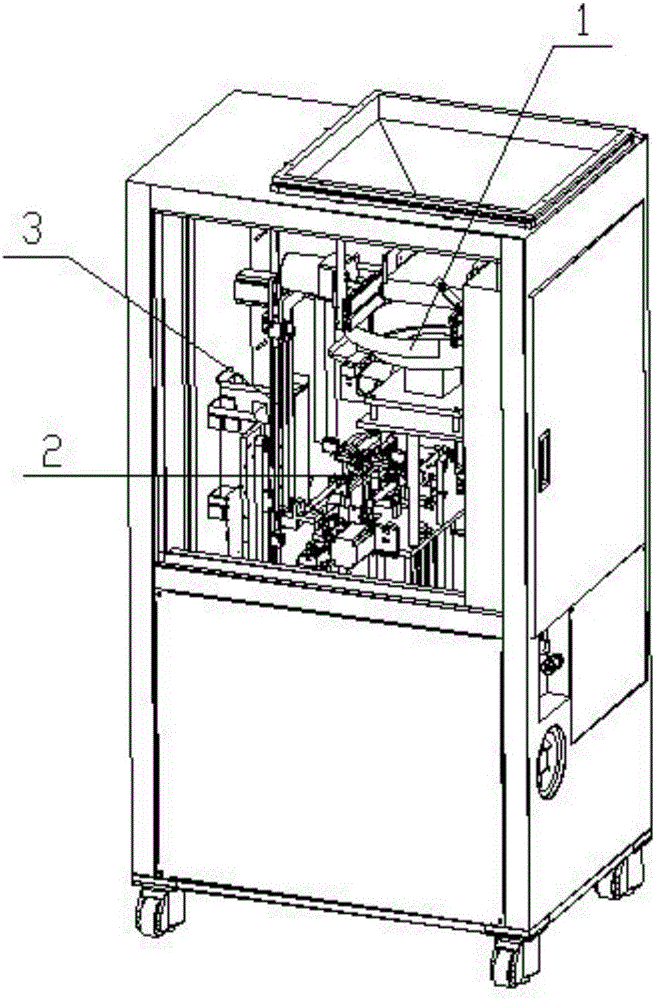

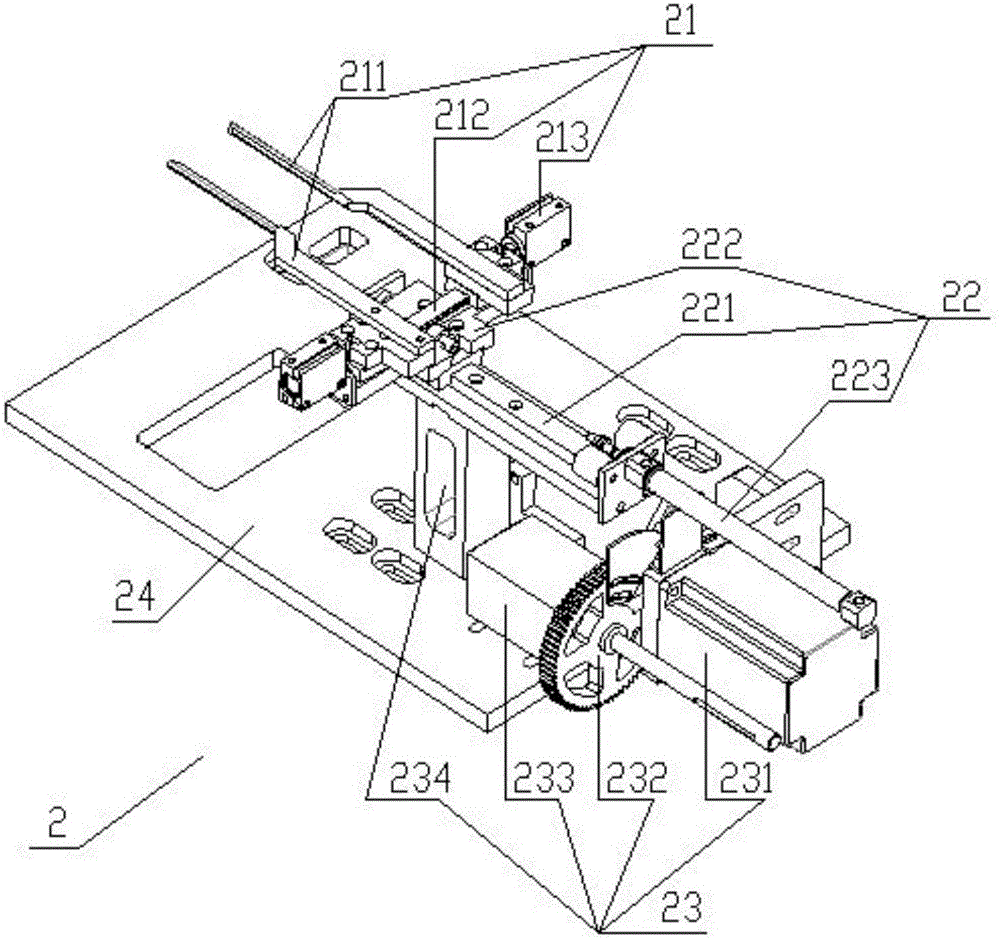

[0034] Embodiment: a kind of tea packing machine, as Figure 1~6 As shown, it includes automatic feeding device 1, flip-type jaw mechanism 2, packaging filling switching mechanism with inner bag 3, packaging filling switching mechanism without inner bag 4, control system and other necessary components of the tea packaging machine, automatic feeding The device 1 is arranged at the feeding position of the tea packaging machine, and the control system controls the cooperative work of each part.

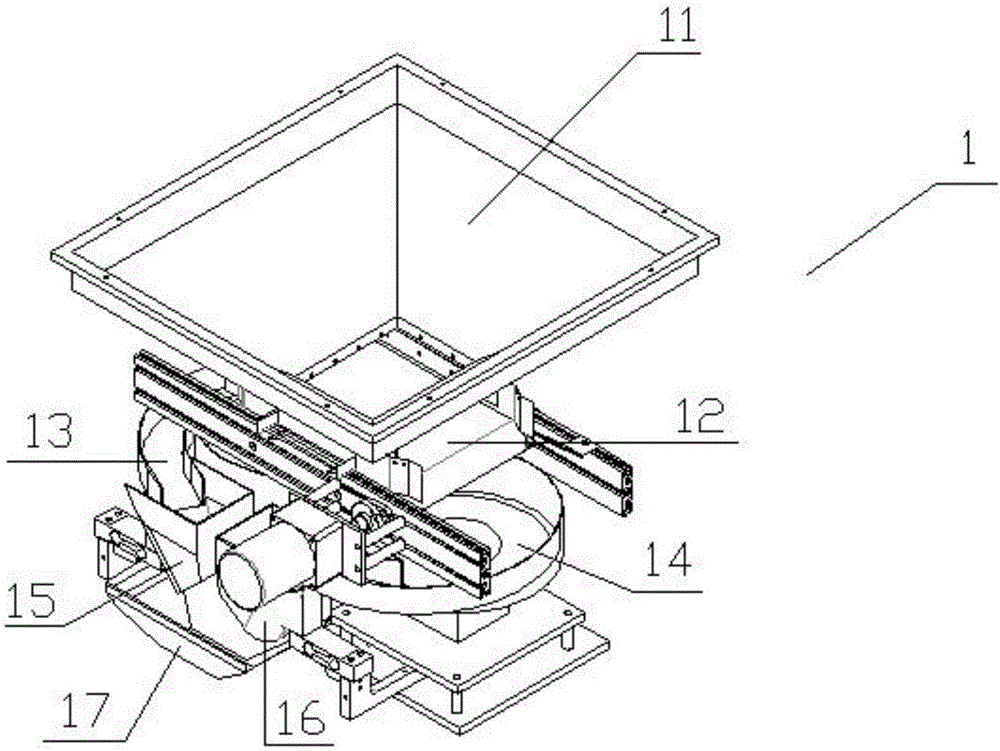

[0035] Such as figure 2 As shown, the automatic feeding device 1 includes a hopper 11, a belt shunt conveying device 12, a left vibrating feeding tray 13, a right vibrating feeding tray 14 and a collective lower hopper. Upper hopper 11 is arranged on the top of belt diversion conveying device 12 , and left vibrating feeding tray 13 and right vibrating feeding tray 14 are respectively arranged below the left and right split ports of belt diverting conveying device 12 . Summarizing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com