Oriented flexible heat conduction material as well as forming technology and application thereof

A heat-conducting material and molding process technology, applied to directional flexible heat-conducting materials and their molding processes and application fields, can solve the problems of increased heat accumulation and decreased product reliability, and achieve a simple process, improved heat dissipation effect, and easy large-scale production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

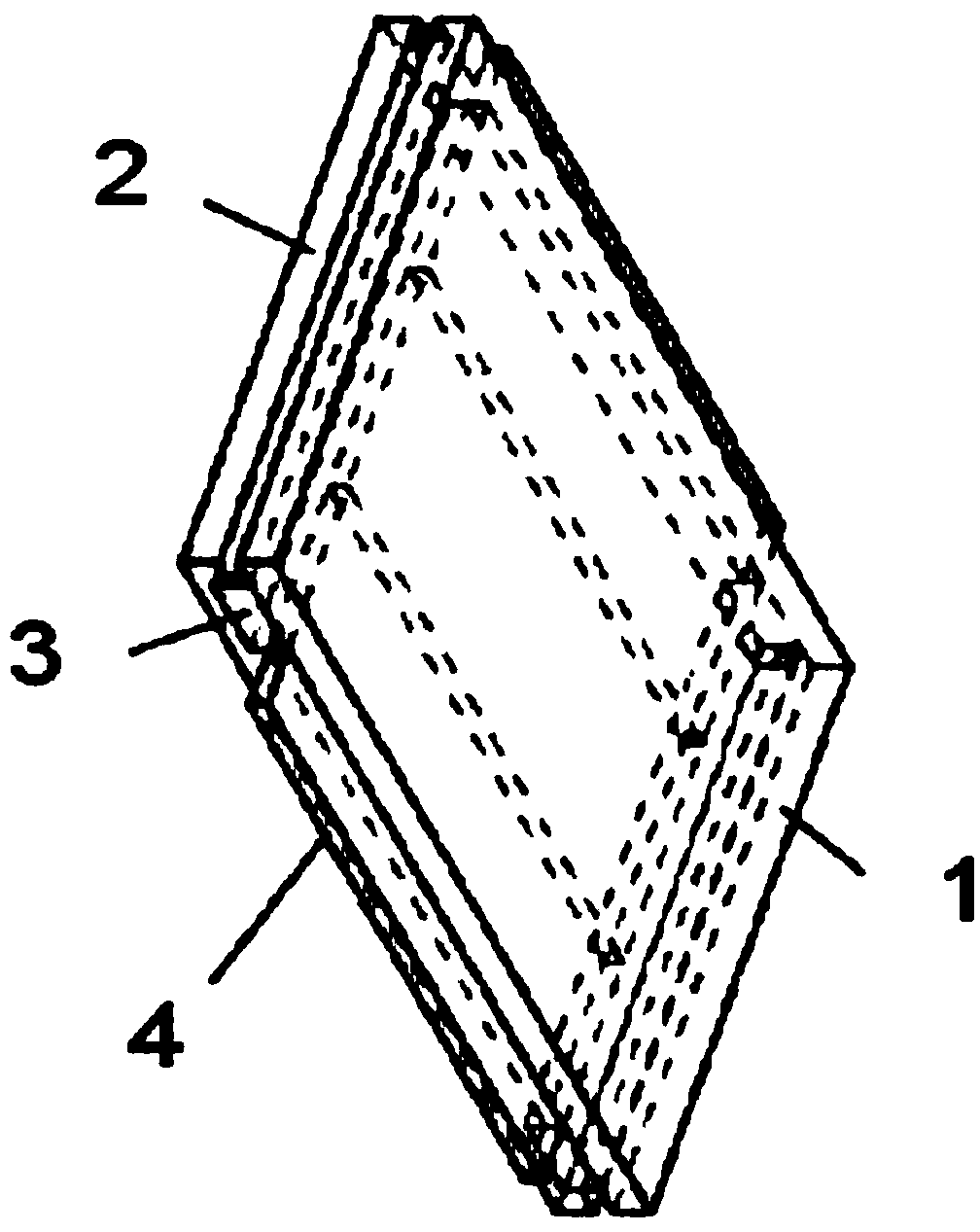

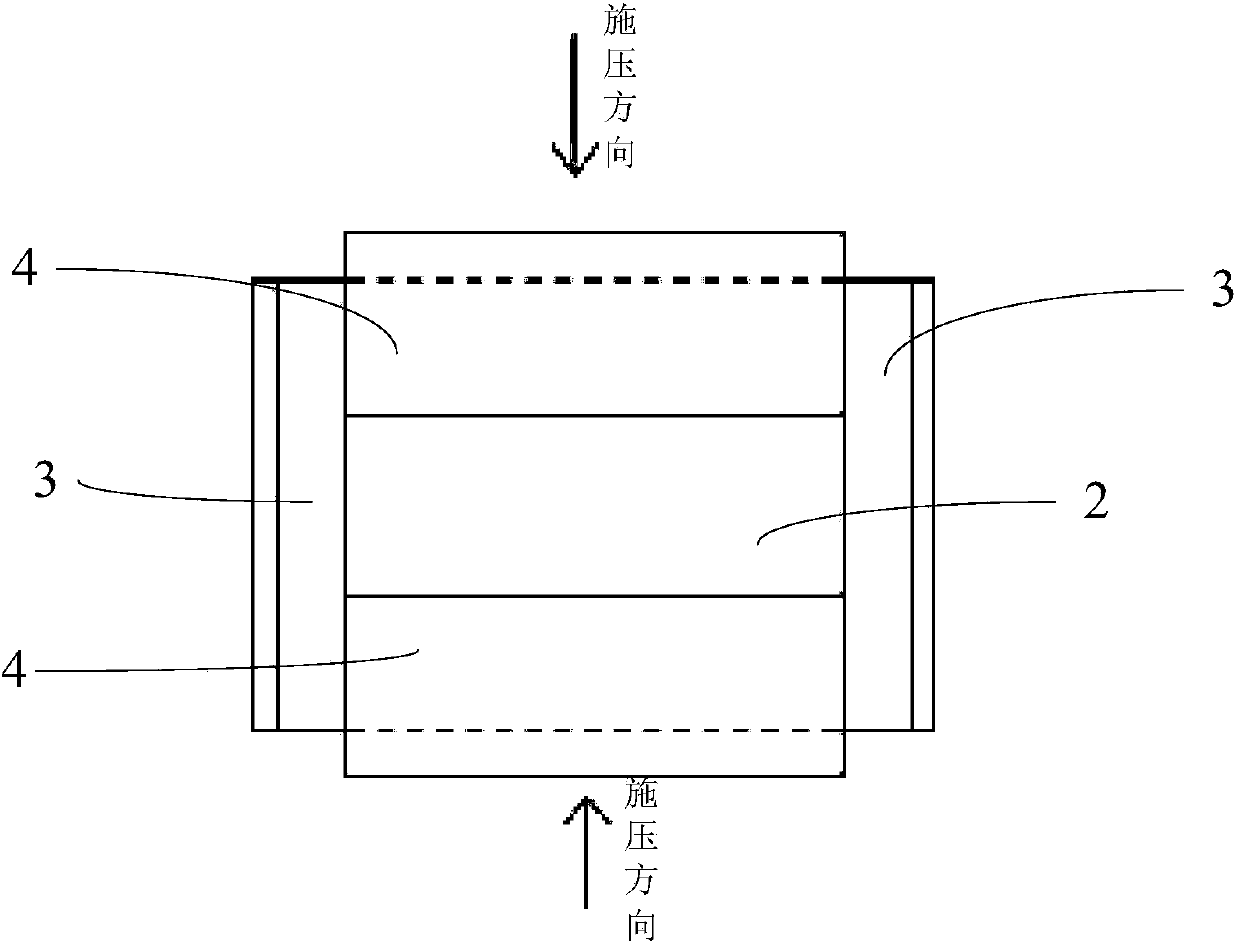

[0080] A molding process of an oriented flexible heat-conducting material, comprising the following steps:

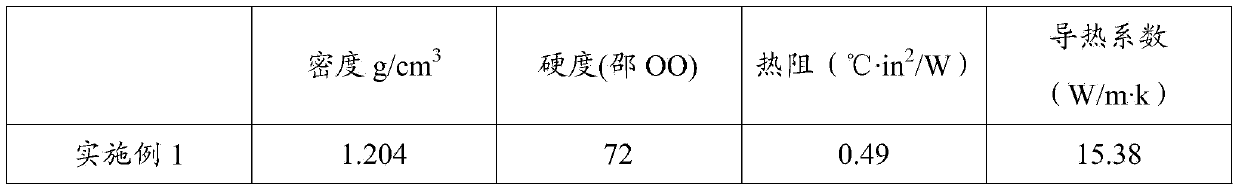

[0081] Put 100 parts of vinyl-terminated polysiloxane into the kneader, 5 parts of fumed silica, 10 parts of alumina, 5 parts of polysiloxane containing silicon-hydrogen bonds, and 0.2 parts of alkynyl cyclohexanol, and knead After uniformity, add 0.1 part of platinum catalyst and 40 parts of expanded graphite and knead evenly to obtain the rubber material, take out the rubber material, put it into the directional molding mold, close the upper template, and simultaneously Pressure forming, the pressure method is 10Mpa air pressure, the time is 0.5min, and then heated and vulcanized (120°C, 60min), the movable mold bar is withdrawn, the upper mold is opened, and the vulcanized sample after orientation molding is taken out, and the oriented flexible thermal conductive material is obtained. .

[0082] Preparation of the thermally conductive sheet: Cut the obtained oriente...

Embodiment 2

[0086] A molding process of an oriented flexible heat-conducting material, comprising the following steps:

[0087] Put into the kneader 100 parts of vinyl-terminated polysiloxane, 5 parts of fumed white carbon black, 5 parts of boron nitride, 3 parts of polysiloxane containing silicon-hydrogen bond, 0.2 part of alkynyl cyclohexanol, After kneading evenly, add 0.1 part of platinum catalyst and 40 parts of expanded graphite and knead evenly to obtain the rubber material, take out the rubber material, put it into the directional molding mold, close the upper template, and place in two opposite directions parallel to the template At the same time, pressure is applied to form, the pressure method is 10Mpa air pressure, the time is 5min, and then heated and vulcanized (120°C, 60min), the movable mold bar is withdrawn, the upper mold is opened, and the vulcanized sample after orientation molding is taken out, and the oriented flexible thermal conductive material is obtained. .

[0...

Embodiment 3

[0092] A molding process of an oriented flexible heat-conducting material, comprising the following steps:

[0093] Put 100 parts of vinyl-terminated polysiloxane into the kneader, 5 parts of precipitated silica, 5 parts of aluminum oxide, 4 parts of polysiloxane containing silicon-hydrogen bonds, and 0.2 parts of alkynyl cyclohexanol, and knead After uniformity, add 0.1 part of platinum catalyst and 45 parts of expanded graphite and knead evenly to obtain the rubber material, take out the rubber material, put it into the directional molding mold, close the upper template, and simultaneously Pressure forming, the pressure method is 10Mpa air pressure, the time is 2min, and then heat vulcanization (120°C, 60min), exit the movable mold bar, open the upper mold, take out the vulcanized sample after orientation molding, and then obtain the oriented flexible thermal conductive material.

[0094] Preparation of the thermally conductive sheet: Cut the obtained oriented flexible therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com