Dry type electrostatic separator for dry type recovery production line of waste circuit board

An electrostatic sorting and waste circuit board technology, applied in the sorting field, can solve the problems of high impurities and low sorting efficiency, achieve the effects of low power consumption, improve sorting efficiency, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

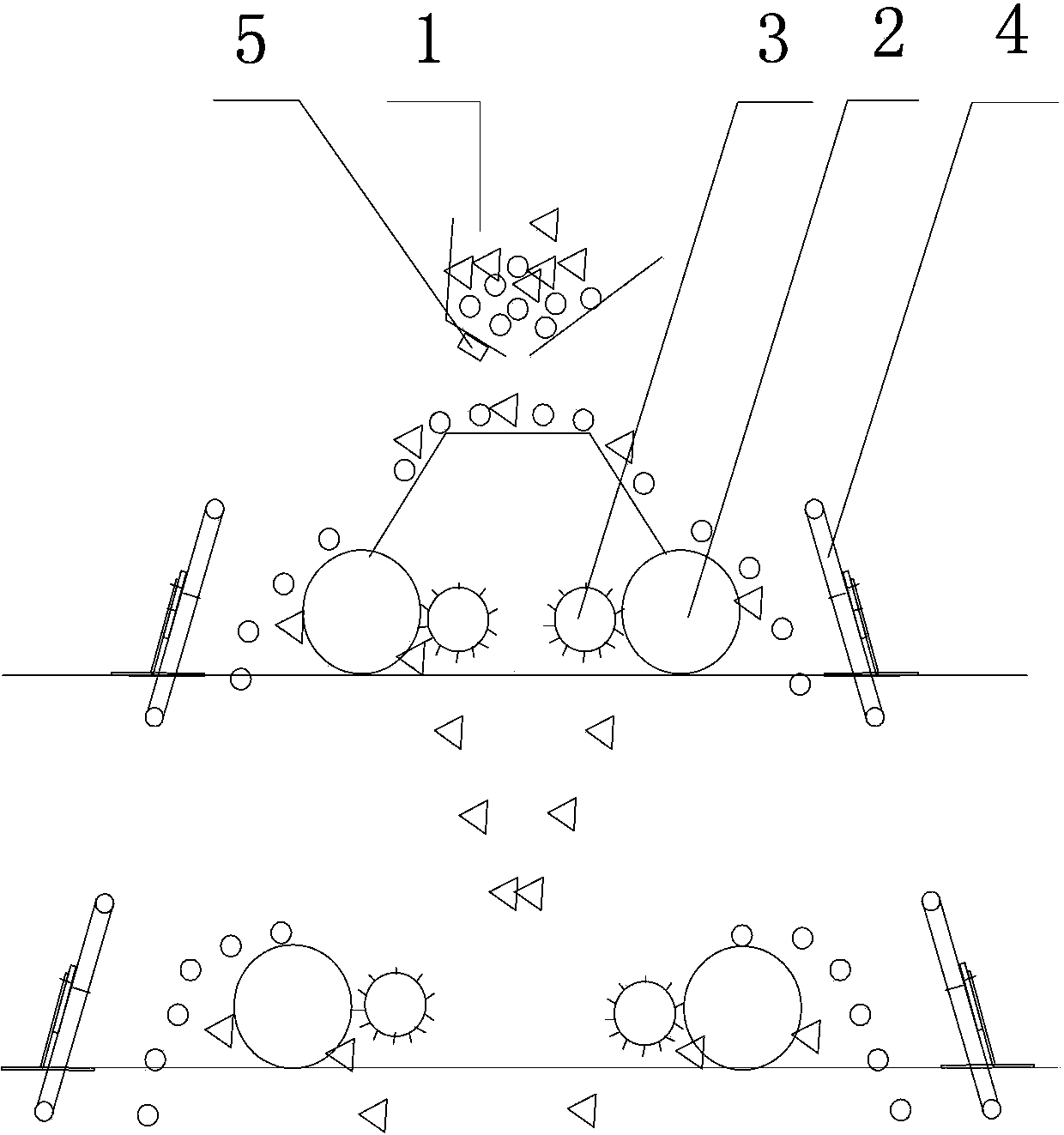

[0015] See figure 1 , the present invention is a dry type electrostatic sorting machine used in a waste circuit board dry recovery production line, comprising a feed hopper 1, a grounded sorting drum 2, a sorting brush 3, and an electrostatic rack 4; at least the feed hopper 1 At least one electromagnetic oscillator 5 is provided on the outlet to drive the feed hopper 1 and the pulverized materials in the hopper to vibrate together; Brushes 3 and grounding sorting rollers 2 are provided with electrostatic racks 4 opposite to each other on the outside. There are four groups, and these four groups are distributed in a trapezoidal shape; An electric field is generated between the selection drum 2 and the electrostatic frame 4, and when the pulverized material passes through, the metal particles and non-metallic particles in the pulverized material are separated by the electric field; the sorting brush 3 is used to brush off the particles adsorbed on the grounded sorting drum 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com