Arch breaking bin and discharge unit with same

A technology of arch breaking and seasoning, which is applied in the field of arch breaking warehouses, can solve problems such as the inability to effectively guarantee the taste of dishes, the failure of normal feeding and metering, and high humidity, so as to enhance the versatility of equipment, shorten the feeding time, and reduce the loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described with reference to the accompanying drawings are exemplary and are intended to explain the invention, but not to be construed as limitations on the invention. In the case of no conflict, the embodiments in the application and the features in the embodiments can be mutually exchanged combination.

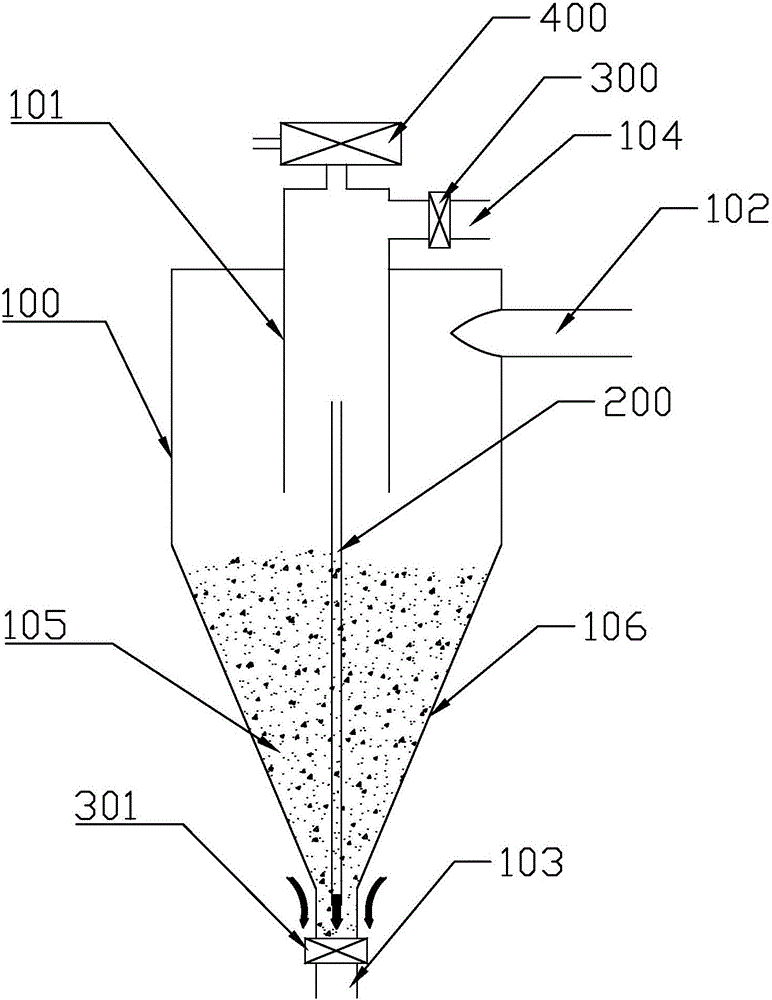

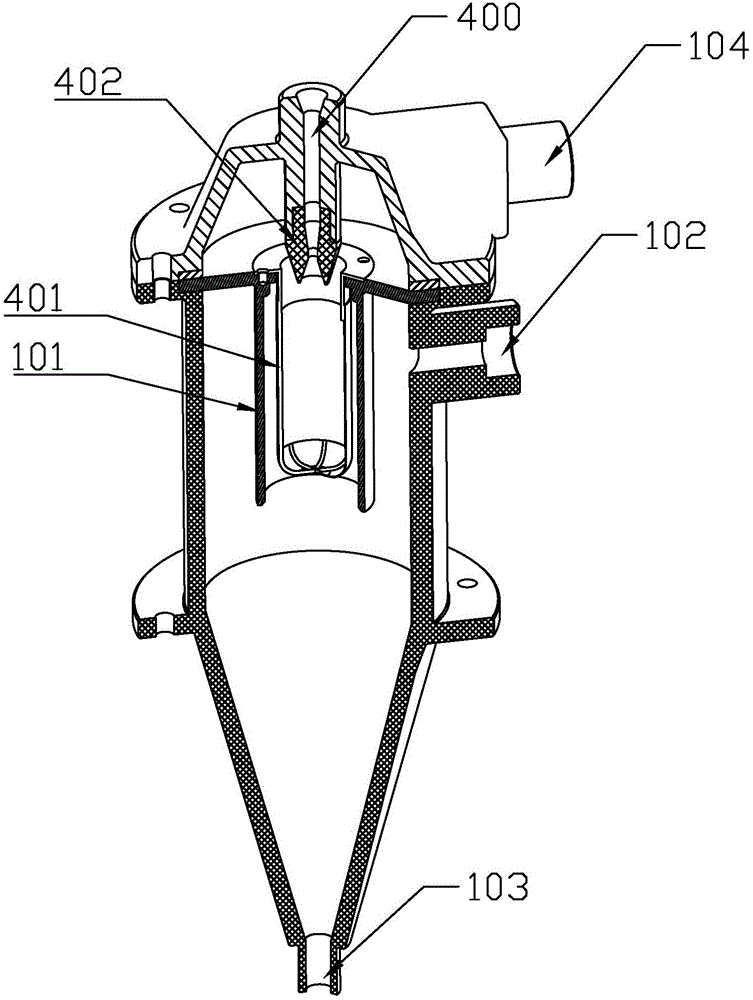

[0035] Such as figure 1 As shown, the broken arch warehouse includes a separation outer cylinder 100, a material inlet 102, a material outlet 103, and an exhaust port 104. In the outer cylinder 100, the gas after gas-solid separation is discharged from the exhaust port 104, the seasoning 105 falls into the separation outer cylinder 100, and is discharged from the discharge port 103. The separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com