Lime bin capable of stably discharging

A lime material and stable technology, which is applied in the field of silos for storing powder materials, can solve the problems of complex mechanism, deterioration of arch breaking effect, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

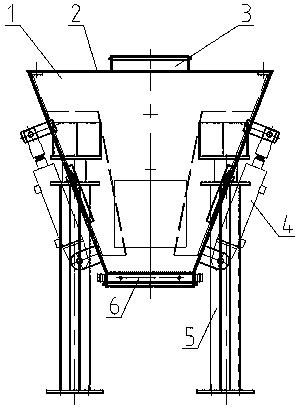

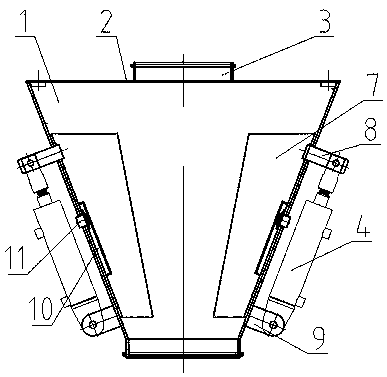

[0020] exist figure 1 The shown lime silo capable of stable discharge includes a silo body 1 in the shape of a rounded table, and the silo body 1 is fixedly installed on six silo legs 5 . A warehouse cover 2 is arranged on the top of the warehouse body 1, and a material injection port 3 is arranged on the warehouse lid 2, and a discharge gate 6 is provided at the lower port of the warehouse body 1, and the discharge gate 6 is an electro-hydraulic flat gate. Two arch breaking push rods 4 are symmetrically arranged on the outside of the bin body 1 .

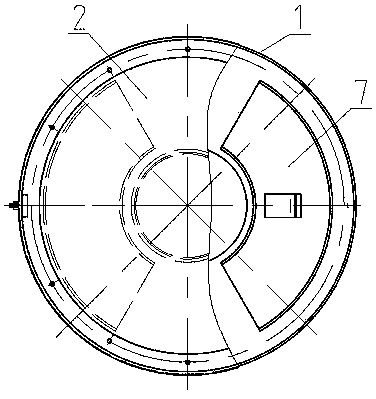

[0021] Such as figure 2 , image 3 As shown, two arch-breaking arc-shaped plates 7 are symmetrically arranged on the inner wall surface of the warehouse body 1, and each arch-breaking arc-shaped plate 7 corresponds to an arch-breaking push rod 4 located outside the warehouse body 1; The plate 7 slides close to the inner wall of the bin body 1 and can reciprocate up and down along the inner wall. The arch-breaking curved plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com