Vortex arch breaking feeder

A feeder and arch-breaking technology, which is applied in the field of vortex arch-breaking feeders, can solve the problems of material conveying interruption, arching, etc., and achieve the effects of uninterrupted material conveying, small body wear, and high arch-breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

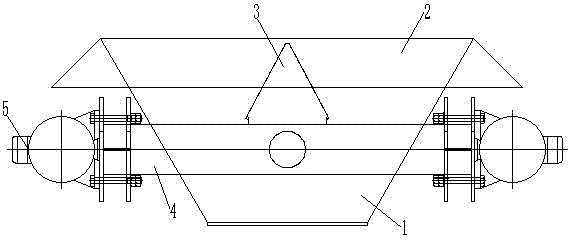

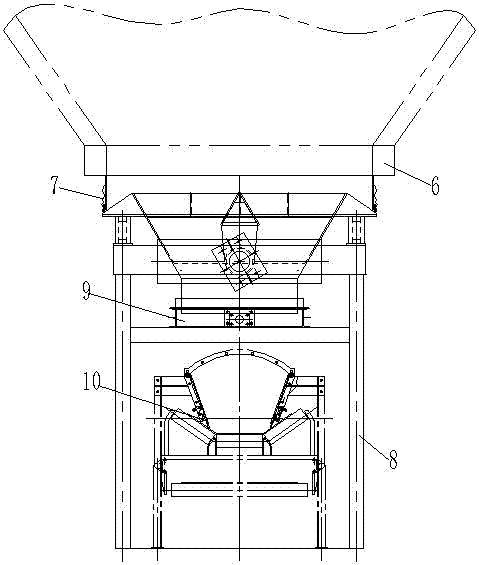

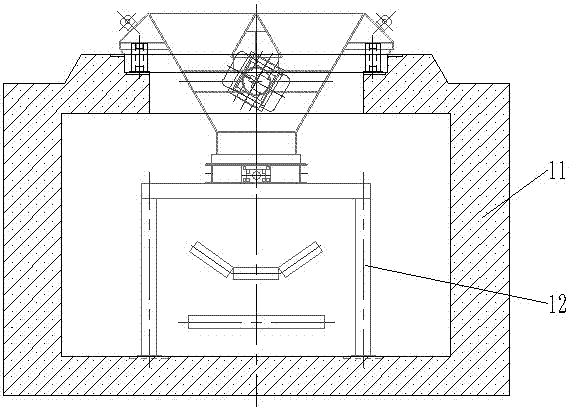

[0018] The specific technical solutions of the present invention are described in detail in conjunction with the accompanying drawings. Such as figure 1 As shown, the vortex arch-breaking feeder includes a lower hopper 1 and a support cone 2 arranged on the top of the lower hopper 1, and the arch-breaking cone 3 is arranged on the lower hopper 1 through a support beam 4 fixed on the wall of the cone hole of the lower hopper 1 At the inner center position, the top of the arch-breaking cone 3 is placed in the support cone 2, and the support beam 4 outside the lower hopper 1 is provided with two vibration motors 5 with adjustable inclination, and the two vibration motors 5 are arranged symmetrically at 180° And run in opposite directions, the axes of the two vibration motors 5 intersect each other to form an angle of 0° to 90°, which is used to form vortex vibration; by adjusting the distance between the two vibration motors 5 and the center of the equipment, different vibrations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com