Ilmenite powder lifting hopper

A technology of iron ore powder and hopper, applied in the field of ilmenite powder lifting hopper, to achieve the effect of protecting the bucket elevator, breaking the arch and unloading easily, and reducing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

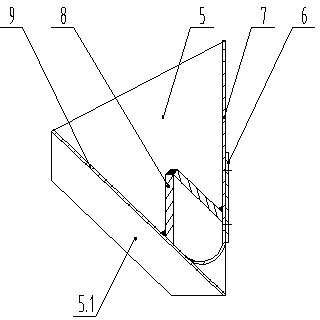

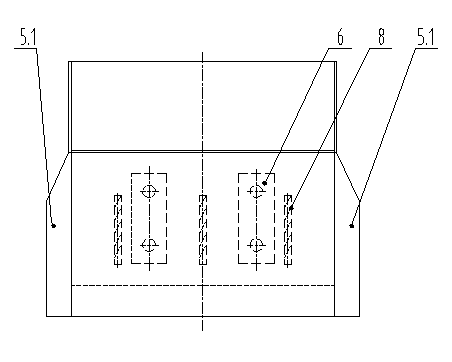

[0017] The hoisting hopper for ilmenite powder shown in the accompanying drawings includes a rear bottom plate 7, a front bottom plate 9, a material guide plate 5, and a fixed reinforcement plate 6; the lower ends of the rear bottom plate 7 and the front bottom plate 9 are sealed and fixedly connected to form a hopper V with an acute angle. shaped structure; the material guide plate 5 is fixedly connected to both sides of the back base plate 7 and the front base plate 9 of the V-shaped structure of the hopper, and one end stretches out from the front base plate 9 to form the material guide part 5.1. In the present embodiment, the material guide plate 5 guide part 5.1 It is in a figure-eight shape that opens outwards; the fixed reinforcing plate 6 used to install the lifting chain is fixedly connected behind the rear bottom plate 7; the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com