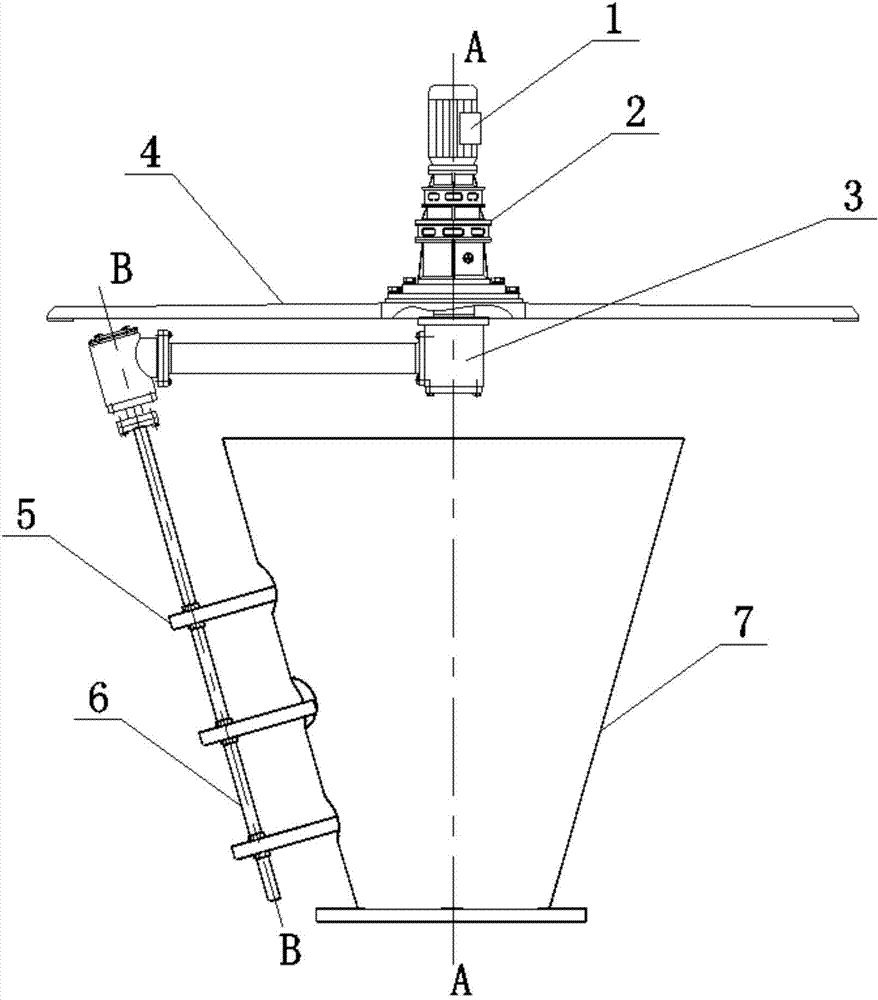

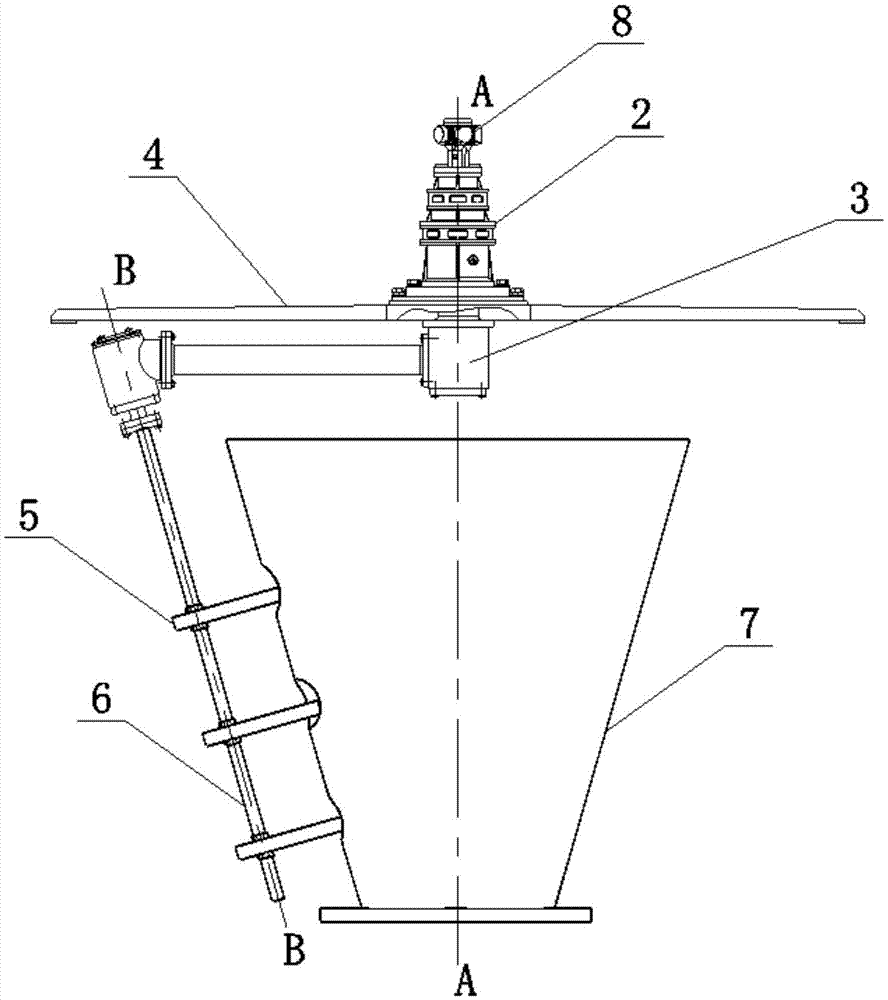

Hopper arch breaking device for materials sensitive to friction and impact

A technology of arch breaking and hopper, applied in the field of hopper arch breaking device, can solve the problems of flying dust, inappropriate arch breaking process, incapable of using dust flammable or explosive materials to break arch, etc., so as to avoid potential safety hazards and ensure safety. , good effect of breaking the arch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

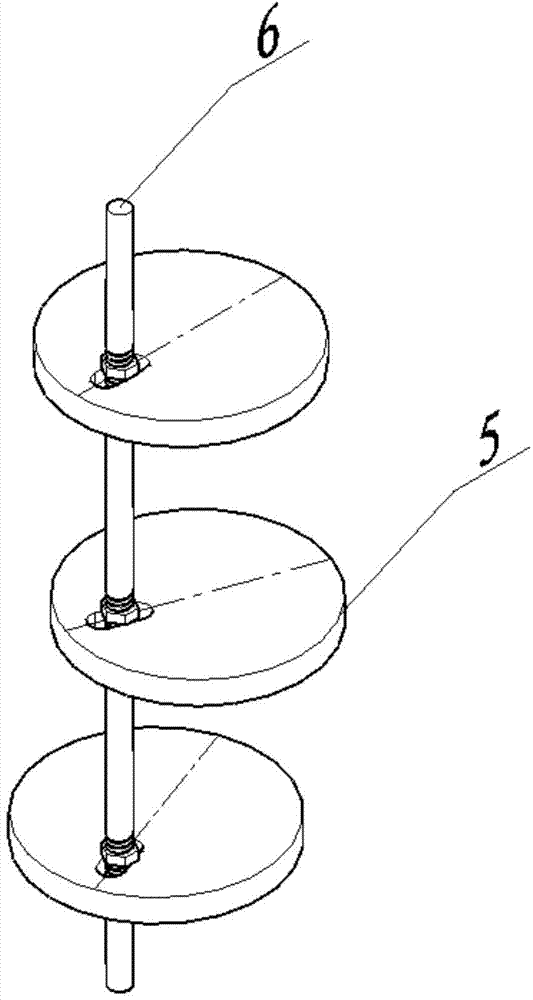

[0046] Dinitropentamethylenetetramine (DPT) feeding is carried out by using the motor-driven hopper arch-breaking device for friction and impact sensitive materials designed by the present invention. The explosion-proof grade of the motor is Exd‖BT4, and the total volume of the hopper cylinder is 50L. The material of the hopper is conductive rubber. The rotation speed of the arch breaking shaft around the symmetrical axis of the hopper is 3.8rpm, and the rotation speed around its own axial direction is 65rpm. The diameter of the arch breaking wheel is 20cm, and the maximum deformation depth of the hopper is 5cm. Three arch breaking wheels are arranged at equal intervals on the arch breaking shaft, and the phase angle between adjacent arch breaking wheels is 12°. During the use process, the fluctuation range of feeding speed is within 5%, and there is no bridging, rat hole (core pulling), compaction and other bad phenomena.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com