A fully automatic assembly process for oil pump accessories

An assembly process and fully automatic technology, applied in the field of oil pump assembly, can solve the problems of low accuracy, low assembly efficiency, and the spring cannot be smoothly transferred to the spring installation groove on the oil pump, etc., to achieve automatic assembly and eliminate uneven compression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

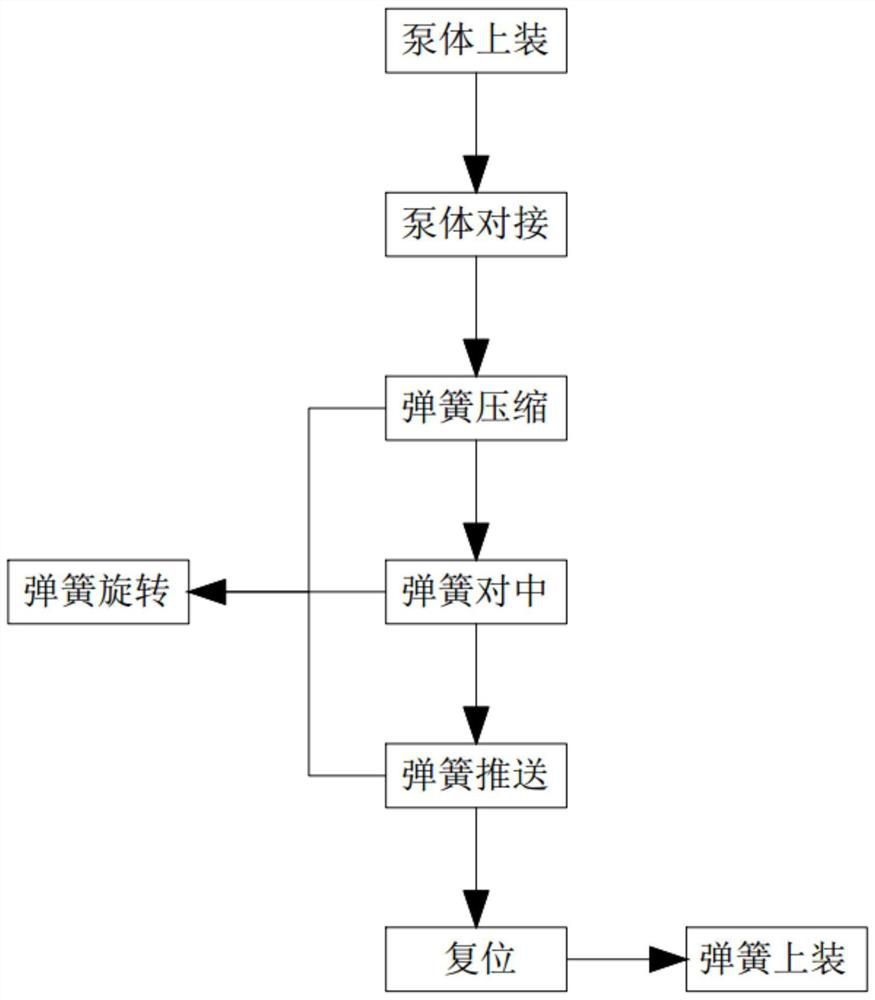

[0058] Such as figure 1 As shown, a fully automatic assembly process for oil pump accessories includes the following steps:

[0059] Step a), the pump body is installed, and the pump body 1 is manually placed in the placement groove 21 set on the installation seat 2 and the pump body 1, so that the pump body 1 is positioned by the placement groove 21;

[0060] Step b), the pump body is docked, after the pump body 1 is positioned, the push cylinder 3 drives the compression groove 51 loaded with the spring 12 vertically downward along the guide of the optical axis 50, and the lower end of the compression groove 51 docked with the upper opening of the spring mounting groove 11 on the pump body 1;

[0061] Step c), the spring is compressed, and after the lower end of the compression groove 51 is docked with the spring installation groove 11 on the pump body 1, the push cylinder 3 drives the push block 41 to continue pushing downward, and the compression groove 51 51 is fixed, th...

Embodiment 2

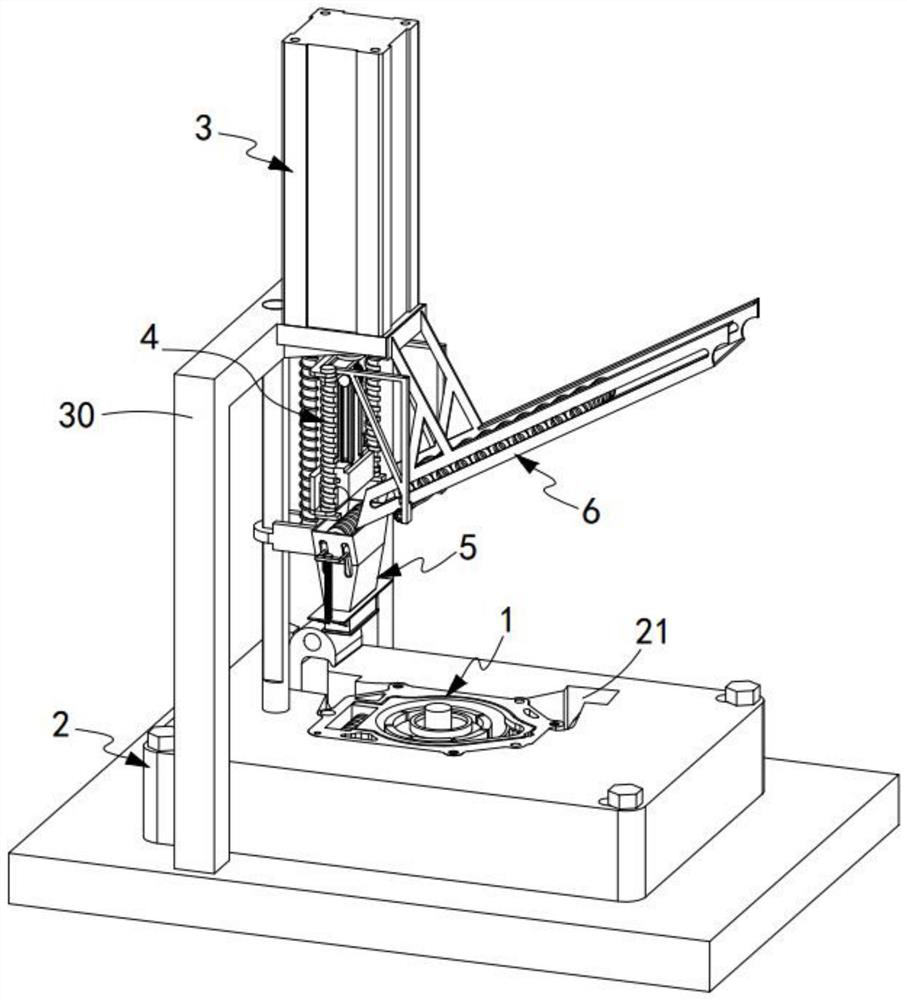

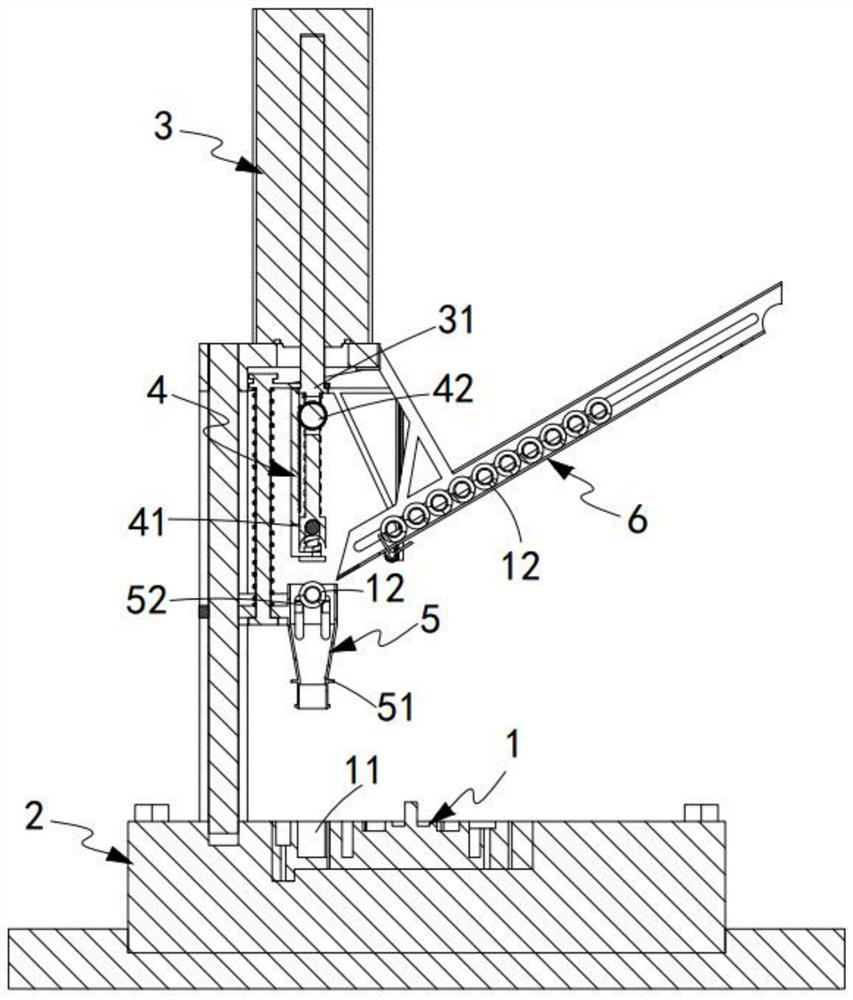

[0080] Such as figure 2 , image 3 , Figure 5 and Figure 12 As shown, a fully automatic assembly device for oil pump accessories in the present invention includes a pump body 1, which is provided with a spring installation groove 11, and the spring installation groove 11 is used for installing a spring 12, and also includes:

[0081] Mounting seat 2, the mounting seat 2 is provided with a placing groove 21 that is shaped like the pump body 1, the pump body 1 is placed in the placing groove 21, and the spring mounting groove 11 is exposed horizontally;

[0082] Push the cylinder 3, the push cylinder 3 is installed above the mounting seat 2 through the gantry frame 30, and the push end 31 of the push cylinder 3 is vertically pushed downwards vertically to the spring installation groove 11;

[0083] Spring pushing mechanism 4, described spring pushing mechanism 4 is arranged on the pushing end 31 of described pushing cylinder 3, and it pushes described spring 12 by describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com