Main cone elastic guide press-loading device

An elastic and press-fitting technology, applied in the field of the main cone elastic guide press-fitting mechanism, can solve the problems of lack of good control in the assembly process, the main reducer can not work normally, and the product quality is unstable, so as to reduce the labor intensity, Exquisite and practical structure, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

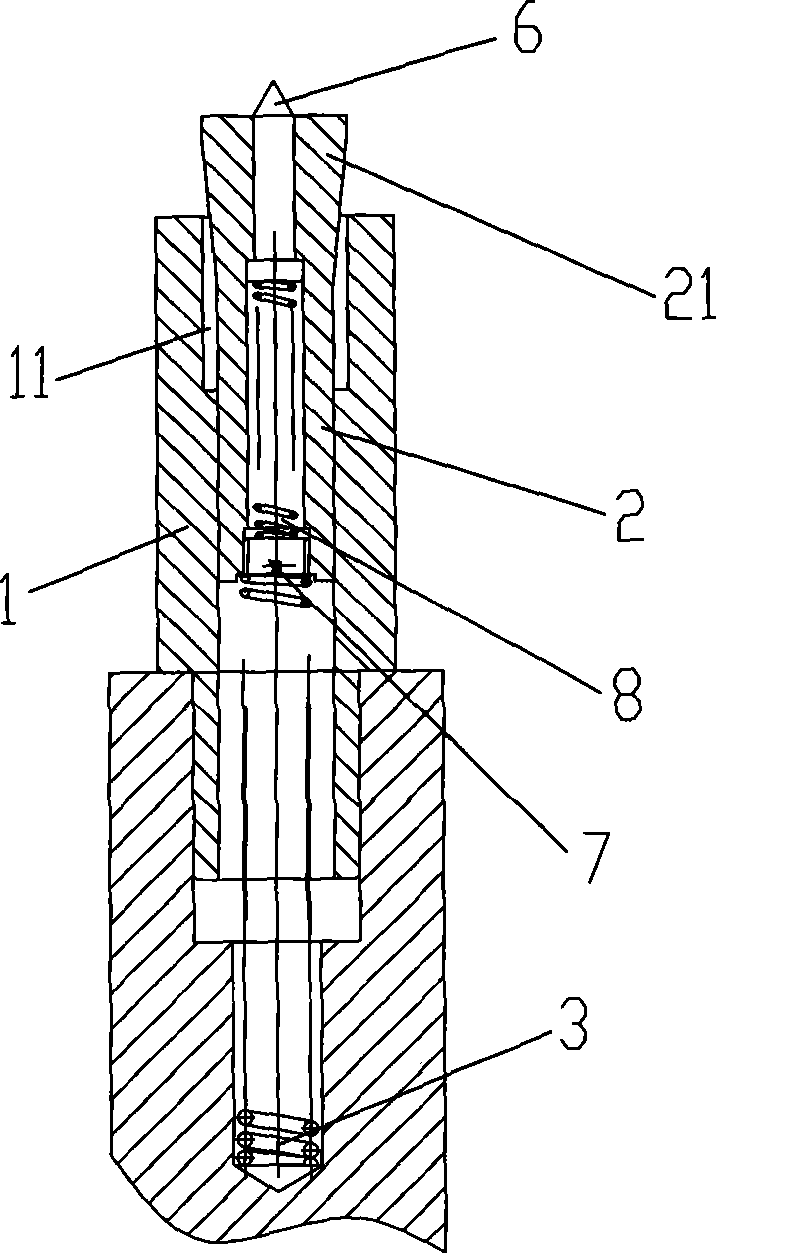

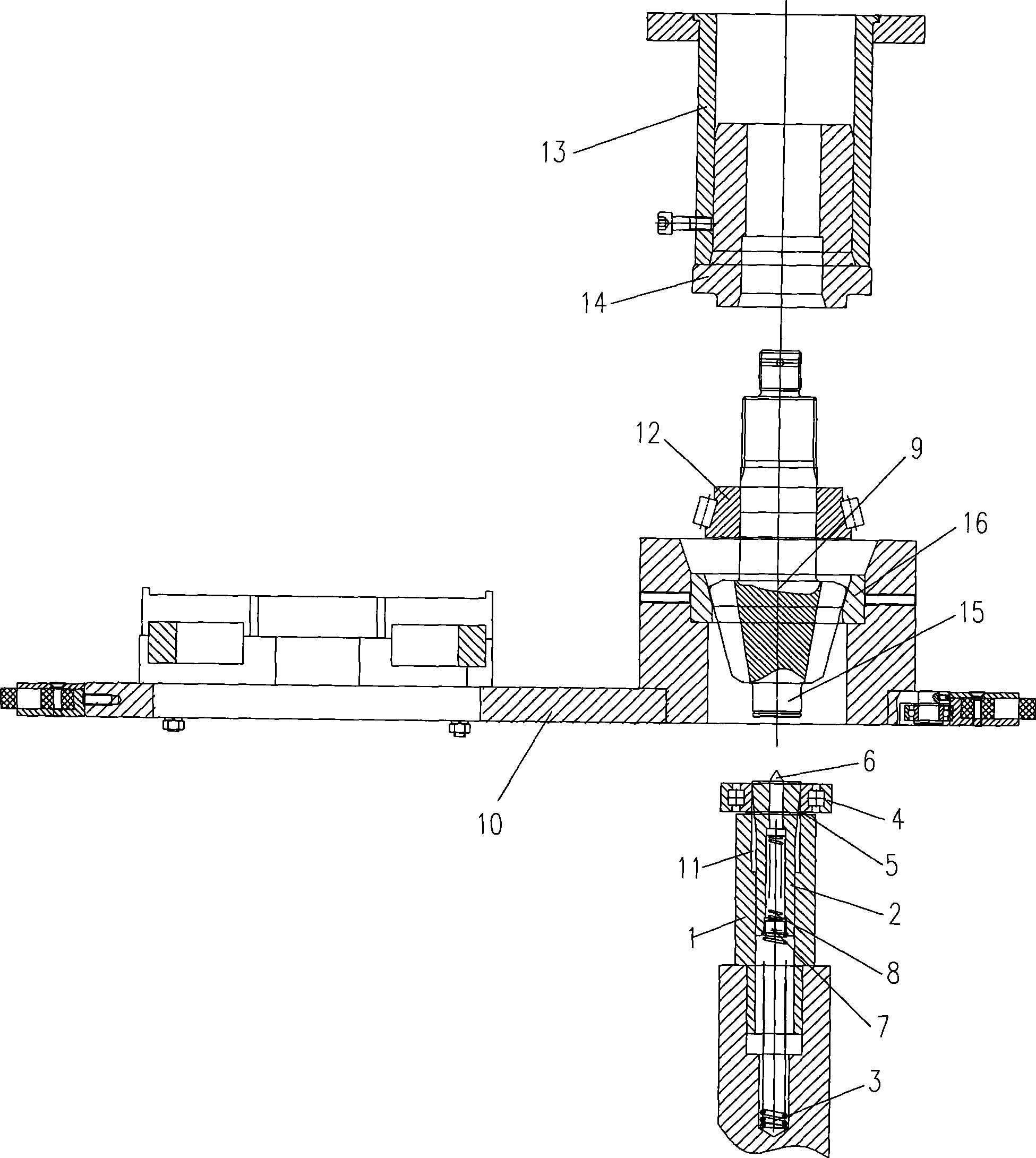

[0020] see figure 1 , set the lower support pressure head 1 that can move upward with the lower oil cylinder shaft in the double-action press system, the lower support pressure head 1 is a casing structure, the guide pressure head 2 is coaxially arranged in the tube of the lower support pressure head 1, and the guide The end face of the tail of the indenter 2 is supported by the pressure spring 3 in the tube supporting the indenter 1, and the guide indenter 2 can slide axially in the tube supporting the indenter 1; Small round platform body 21, the upper section pipe of lower support pressure head 1 is the straight pipe section 11 that can accommodate said round platform body 21, and the guide pressure head 2 supported by stage clip 3 in the pipe protrudes under the support pressure with its upper section round platform body 21. above the top end face of head 1.

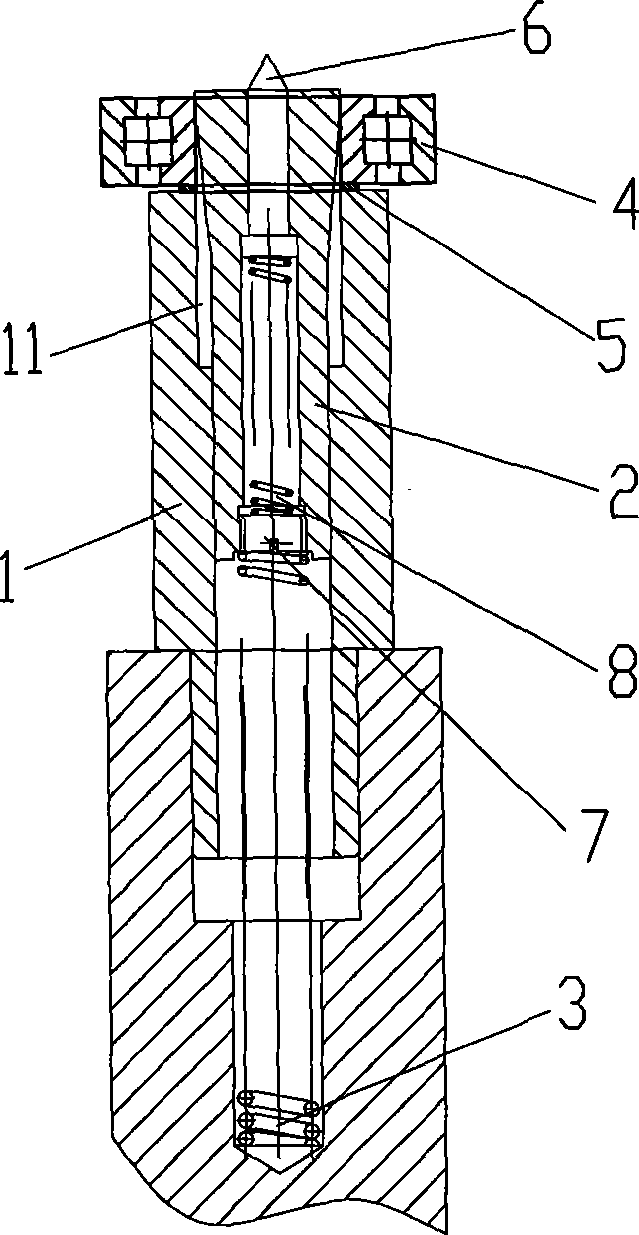

[0021] see figure 2 , the assembled bearing 4 and shaft retaining ring 5 are fitted on the outer periphery of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com