An assembly device and assembly method of an accelerometer excitation ring assembly

A technology for accelerometers and assembly devices, which is applied in the direction of connecting components, material gluing, mechanical equipment, etc., to achieve the effects of improving assembly efficiency, reducing impact, and eliminating quality hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

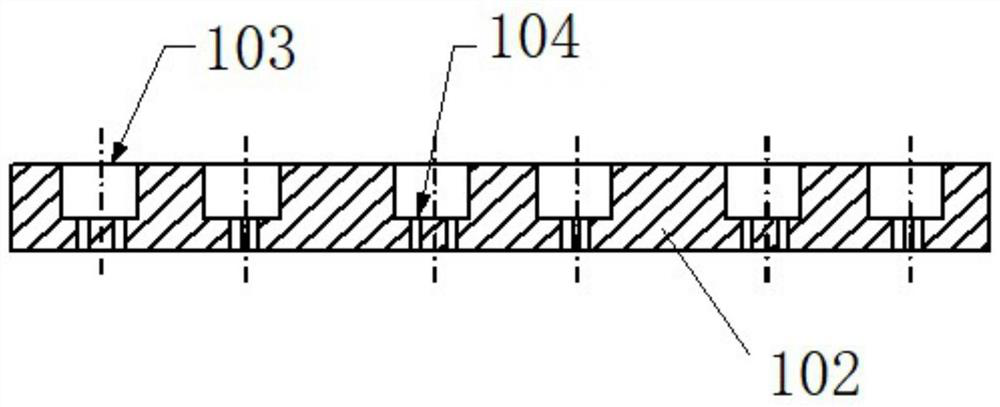

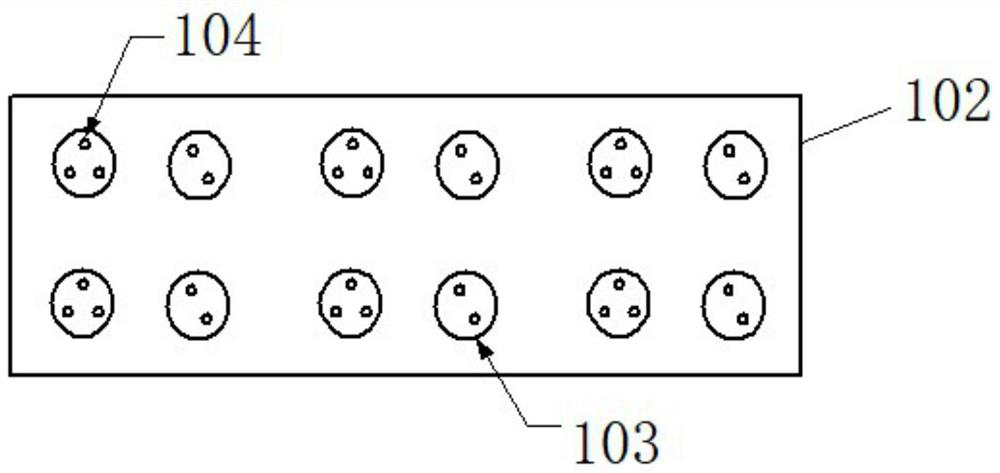

[0029] refer to Figure 1-Figure 3 , this embodiment provides an assembly device for an accelerometer excitation ring assembly, including a terminal assembly manufacturing tooling and a positioning plate 101;

[0030] The tooling for making the terminal assembly includes a tooling main body 102, a plurality of glue filling holes 103 are arranged on the tooling main body 102, and a first positioning hole 104 is arranged on the bottom surface of the glue filling holes 103;

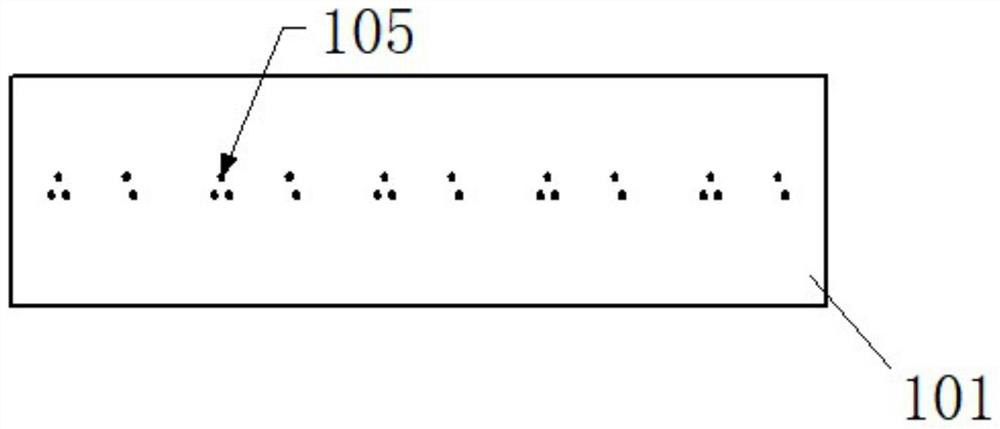

[0031] Multiple sets of second positioning holes 105 are disposed on the positioning plate 101 .

[0032] As a preferred embodiment, the glue filling hole 103 is a counterbore, and the outer diameter of the glue filling hole 103 is slightly smaller than the assembly through hole of the excitation ring.

[0033] As a preferred embodiment, the depth of the glue filling hole 103 matches the depth of the assembly through hole of the excitation ring.

[0034] As a preferred implementation manner, the depth of t...

Embodiment 2

[0039] refer to Figure 4 , this embodiment provides an assembly method of the accelerometer excitation ring assembly, which is assembled by using the assembly device of the accelerometer excitation ring assembly as described in Embodiment 1. For the assembly device of the accelerometer excitation ring assembly, please refer to Embodiment 1. This will not be repeated here.

[0040] The methods include:

[0041] Step S201, installing the terminal in the first positioning hole;

[0042] Step S202, filling the glue hole with adhesive;

[0043] Step S203, curing the adhesive to form a terminal assembly;

[0044] Step S204, taking out the terminal assembly, and installing the terminal assembly in the second positioning hole;

[0045] Step S205, coating the adhesive in the assembly through hole of the excitation ring;

[0046] Step S206 , aligning the assembly through hole of the excitation ring with the adhesive on the terminal assembly, and curing the adhesive in the assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com