NC assembly device for gasket

A technology for assembling devices and gaskets, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of bone injury, worker scratches, slow speed, etc., to reduce the impact, improve the speed and improve the pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

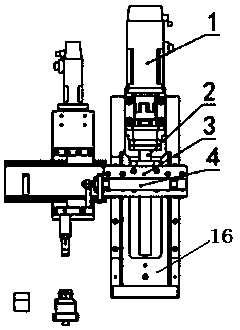

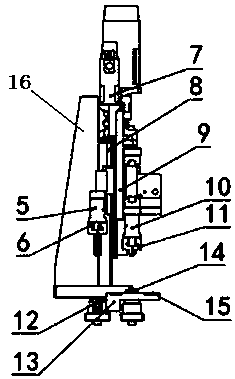

[0022] Such as figure 1 and figure 2 As shown, the numerical control assembly device of the sealing gasket in the embodiment of the present invention includes a lifting mechanism, a transverse feeding mechanism and a clamping mechanism, the transverse feeding mechanism is fixedly connected to the lifting mechanism, and the clamping mechanism is fixedly connected to the transverse feeding mechanism, wherein the clamping mechanism The clamping mechanism is used to clamp the sealing gasket, the transverse feed mechanism is used to control the lateral movement of the clamping mechanism, and the lifting mechanism is used to control the clamping mechanism and the transverse feed mechanism to move up and down together. The lifting mechanism includes a base 16, a lifting servo motor 1, a lifting ball screw 2 and a lifting plate 3, the lifting servo motor 1 is fixedly installed on the base 16, the lifting ball screw 2 is fixedly connected to the output shaft end of the lifting servo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com