Pretreatment method of bonded surface of carbon fiber composite materials

A composite material and carbon fiber technology, used in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of uneven surface quality of grinding, difficult to quantify process, and easy damage to surface fibers, and achieve consistent quality stability. Good, high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will combine Figure 1 ~ Figure 3 The method for pretreatment of the bonded surface of the carbon fiber composite material of the present invention will be further described in detail.

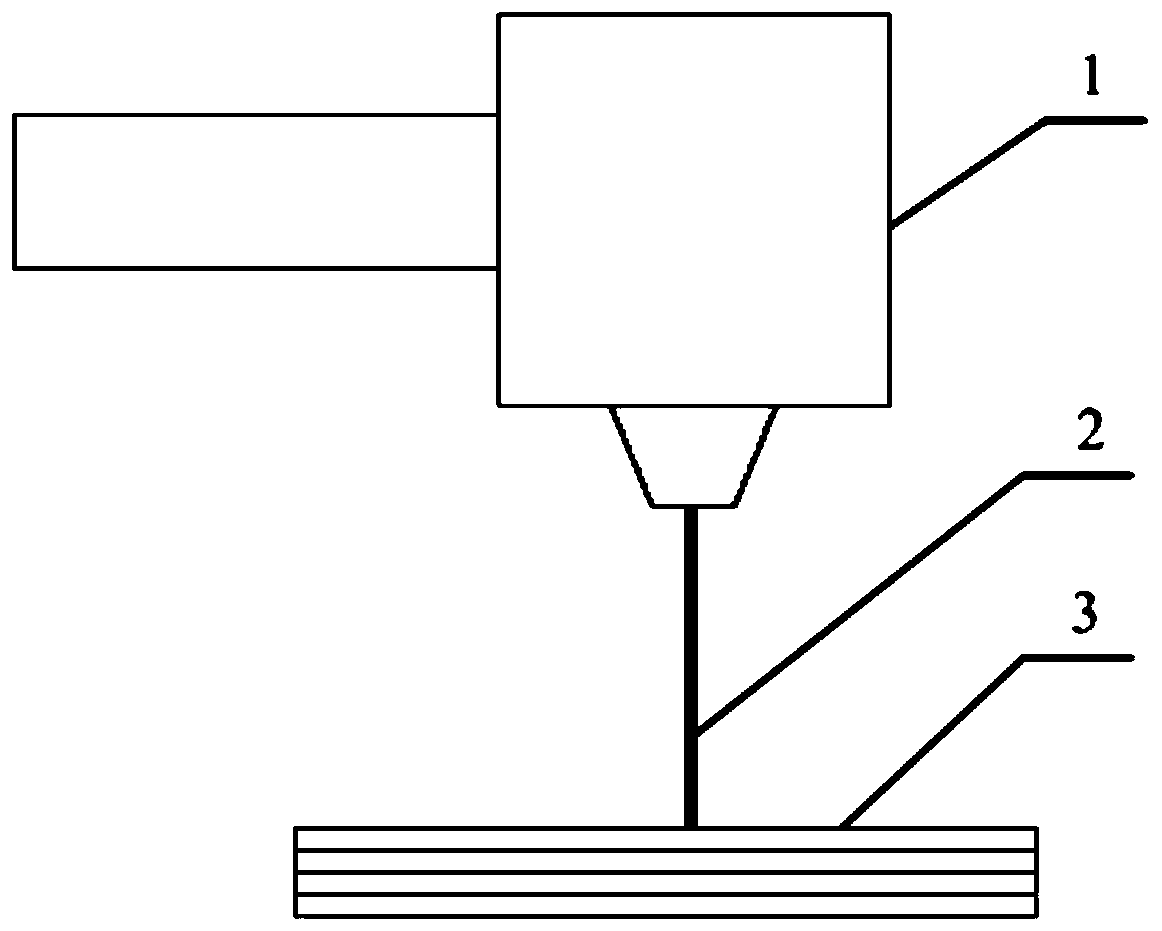

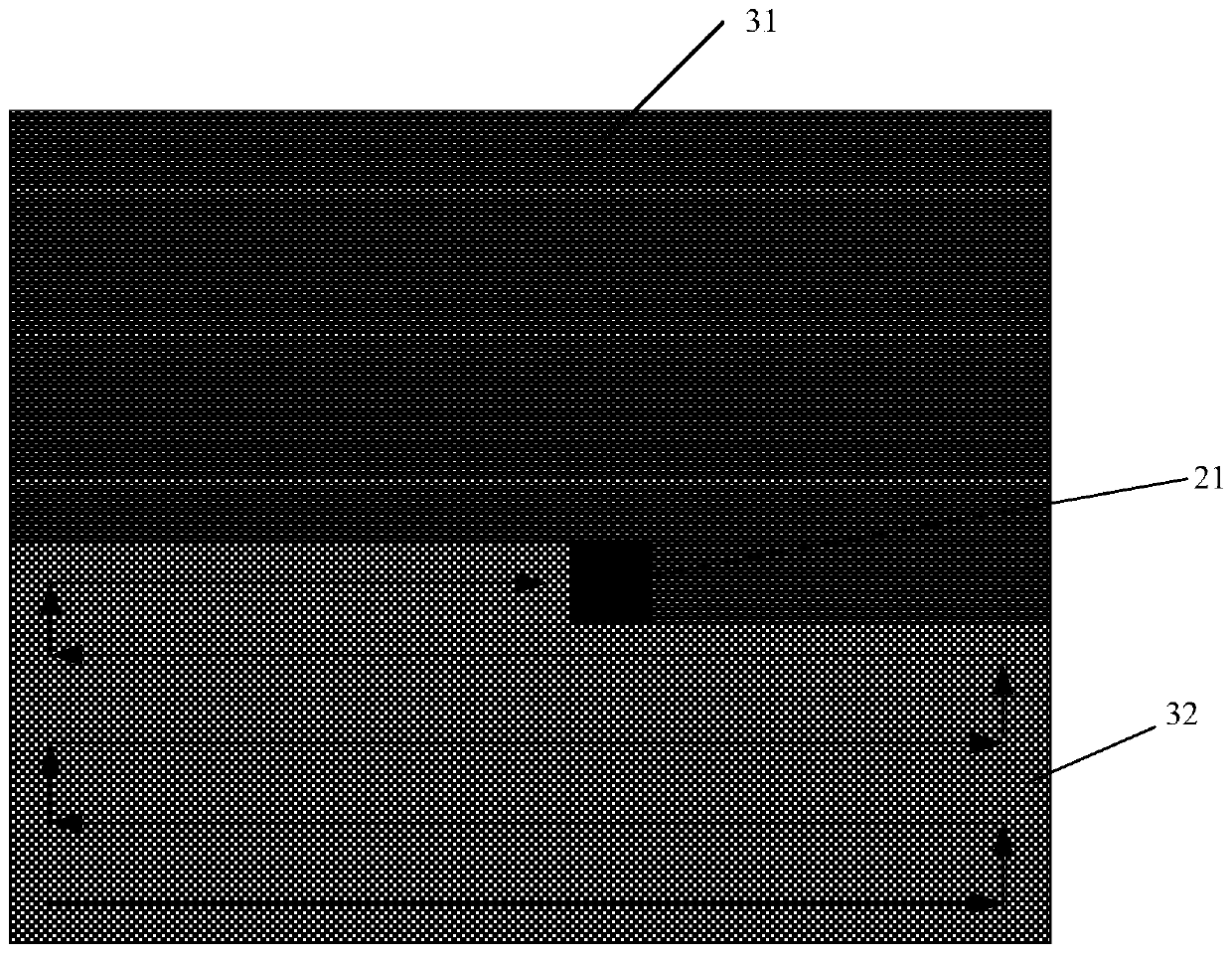

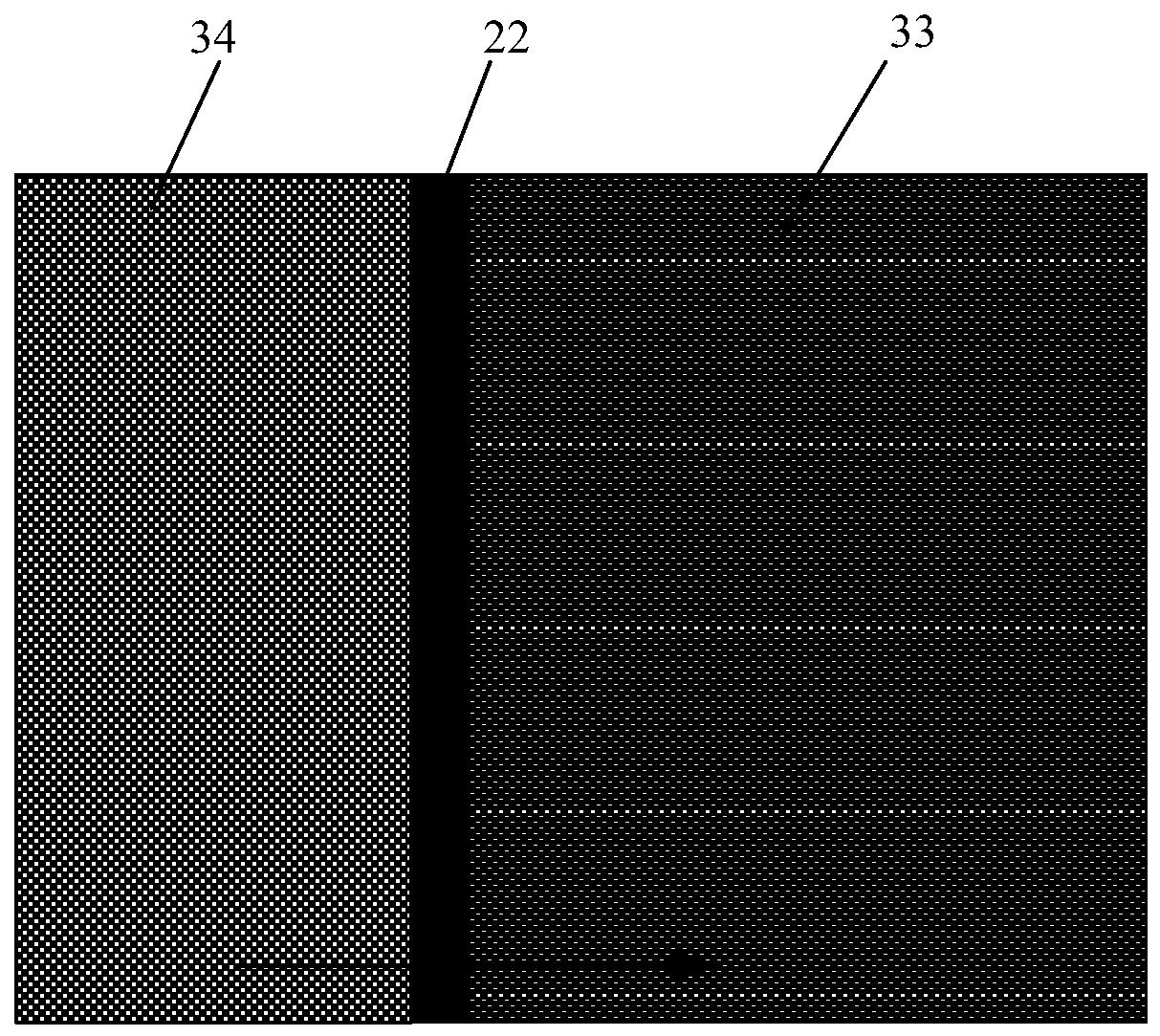

[0019] The carbon fiber composite material bonding surface pretreatment method of the present invention uses an excimer laser to pretreat the carbon fiber composite material bonding surface. Such as figure 1 As shown, the excimer laser 2 generated by the excimer laser 1 is vertically incident on the surface 3 of the carbon fiber composite material (that is, the bonding surface of the carbon fiber composite material), and the excimer laser 2 directly excites the surface material molecules to an electronic state until the material molecules are broken The chemical bond causes the surface to produce erosion phenomenon to form a microscopic rough surface. At the same time, through the potential light effect in the pretreatment process, the activity of the 3 resin groups on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com