A kind of tininbzr high-temperature solder for tial alloy and preparation method and brazing method thereof

A high-temperature brazing material and brazing method technology, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of limiting the high-temperature performance of joints, not mentioning the high-temperature performance of joints, etc., to ensure temperature-resistant performance and low cost. , to ensure the effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

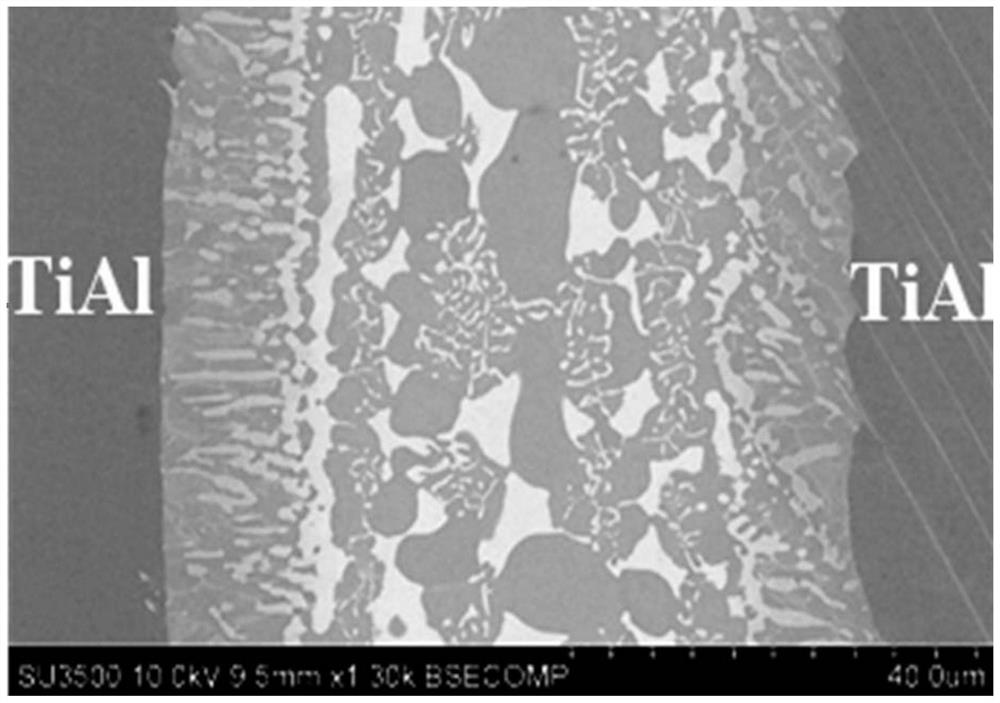

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

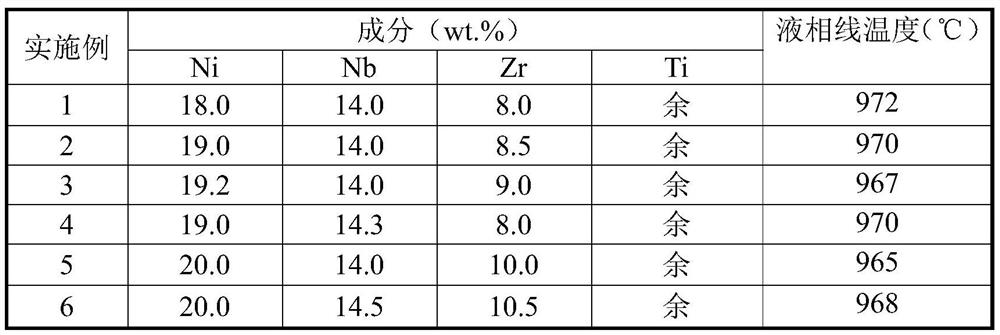

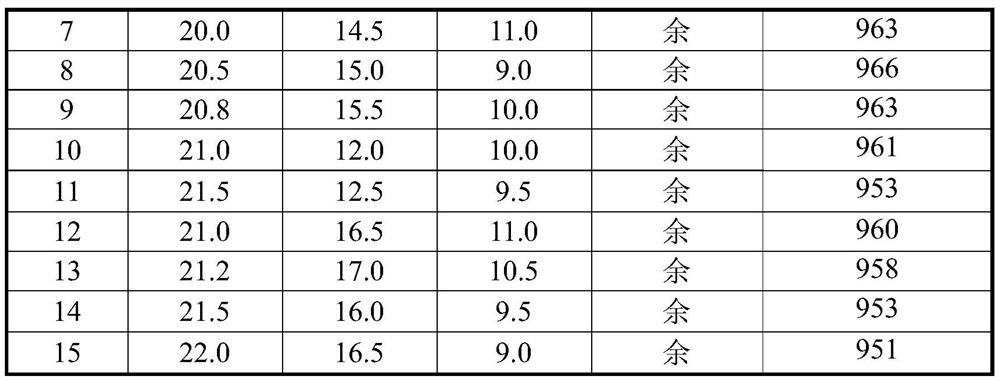

[0038] The following table shows the embodiments of the TiNiNbZr high-temperature brazing filler metal described in the technical solution of the present invention and the composition and weight percentage composition of each embodiment.

[0039]

[0040]

[0041] The TiNiNbZr high-temperature solder described in the foregoing embodiments is prepared according to the following process route:

[0042] (1) Select high-purity Ti, Ni, Nb, Zr with a purity of not less than 99.0%, and weigh by weight;

[0043] (2) Under the protection of argon, the above-mentioned simple substance is smelted into a solder alloy ingot by an arc melting method;

[0044] (3) Prepare solder by one of the following methods:

[0045] A, using argon atomization powder making equipment to prepare alloy powder solder;

[0046] B. Under the protection of argon, use the quench...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com