Actuator and assembling system and method for assembling T/R assembly of array antenna

An array antenna and actuator technology, applied in metal processing, manipulators, metal processing equipment, etc., can solve the problems of inapplicability, poor assembly quality, long cycle, etc., and achieve the effect of improving control accuracy, improving assembly efficiency and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

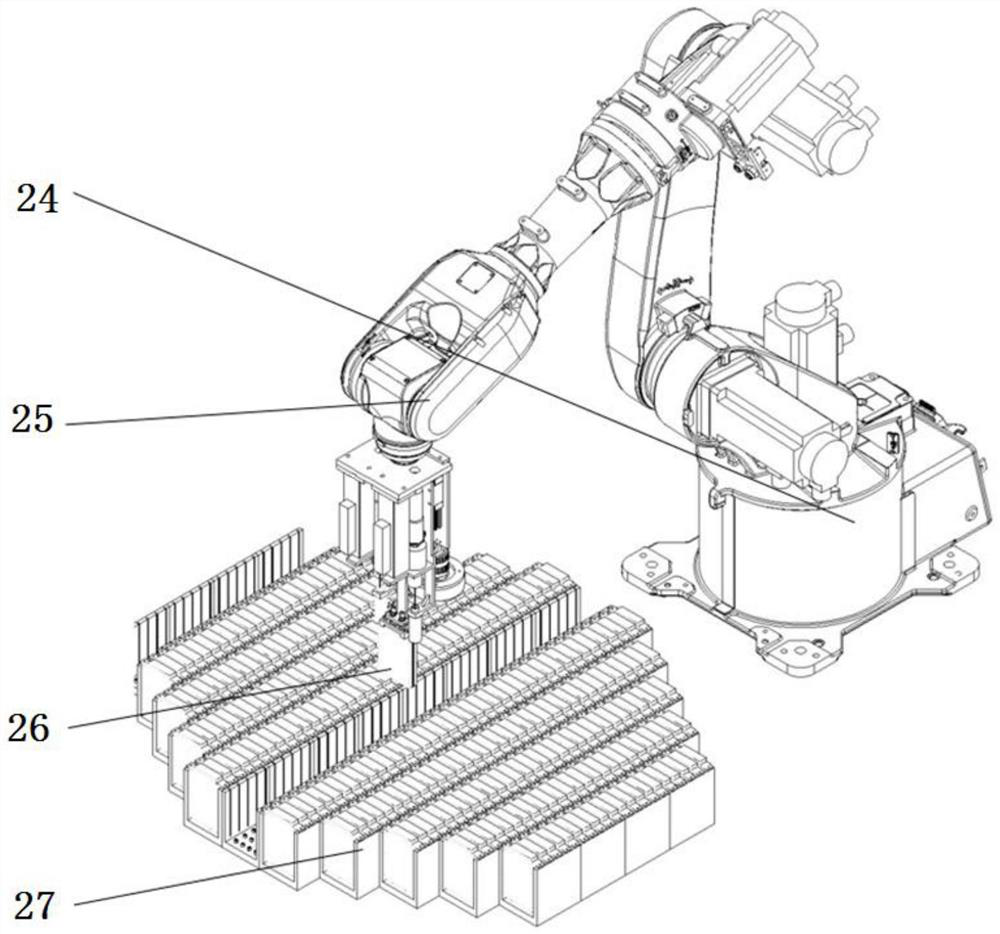

[0030] The actuator, assembly system and method for array antenna T / R assembly assembly of the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

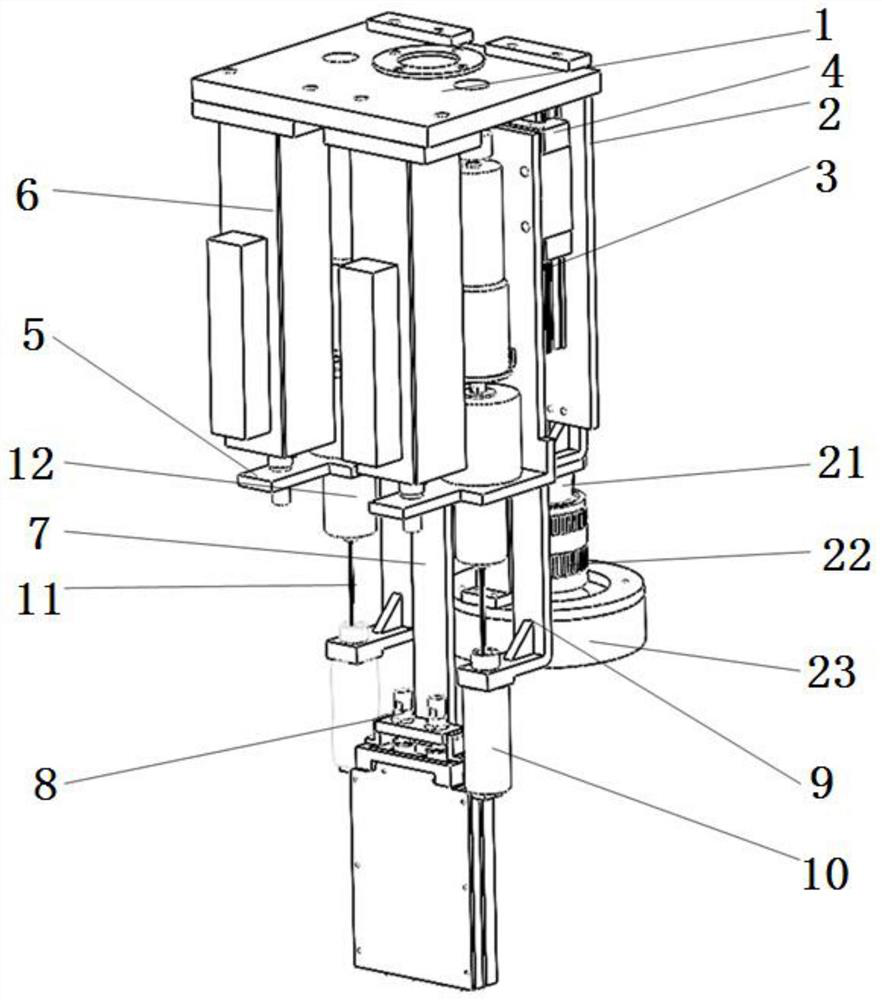

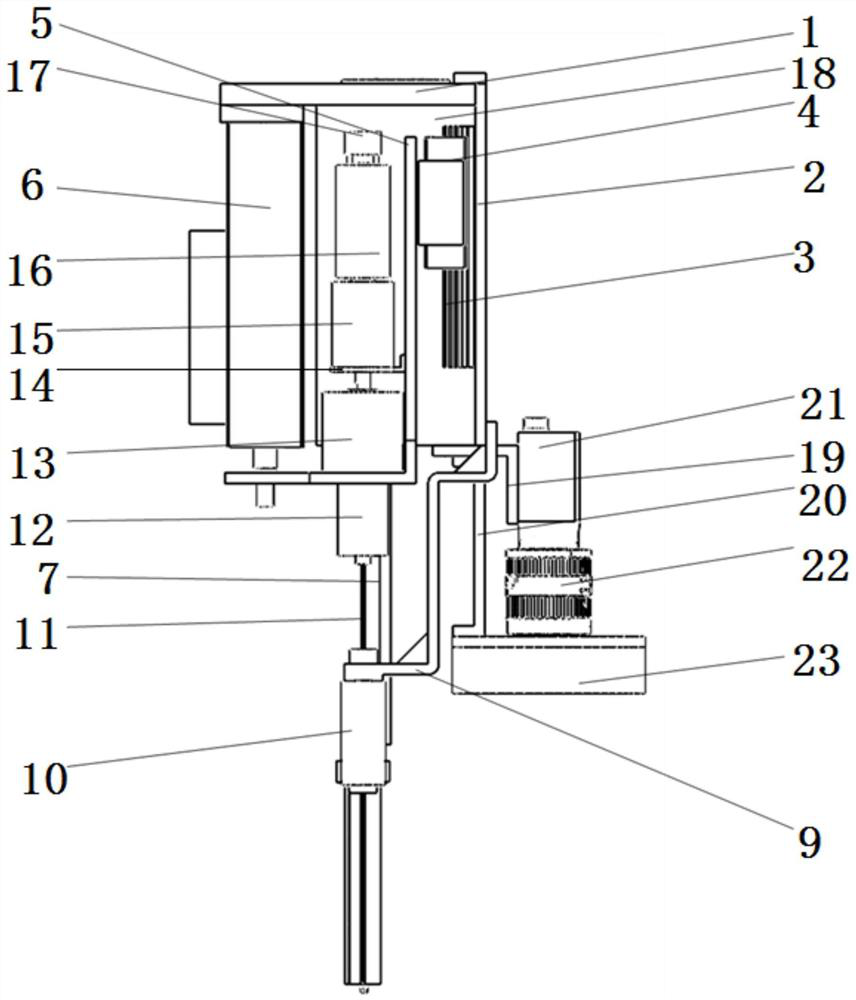

[0031] like figure 1 and figure 2 As shown, the actuator used for assembly of the array antenna T / R assembly includes an upper substrate 1, a vacuum chuck 8, an industrial camera 21, a lens 22, a ring light source 23, two first pallets 5, two strokes of a readable cylinder 6, Two pneumatic chucks 10 and two DC motors 16.

[0032] The upper base plate 1 is arranged horizontally, and a rear side plate 2 is vertically fixed on the left and right sides of the upper base plate 1, and a vertical linear guide rail 3 is fixed on the inner side of each rear side plate 2 . The first supporting board 5 is L-shaped, and the respective long sections of the two first supporting boards 5 are respectively fixedly connected with the sliders 4 of the two linear guide rails 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com