Tubular radiator core combined template

A technology of combining template and radiator, applied in the direction of instruments, instrument cooling, electrical solid devices, etc., can solve the problems affecting the assembly quality and assembly efficiency of the radiator core, the distortion of the radiator core, and the large deformation of the heat sink, etc. Achieve the effect of novel combination structure, reduced impact and uniform spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

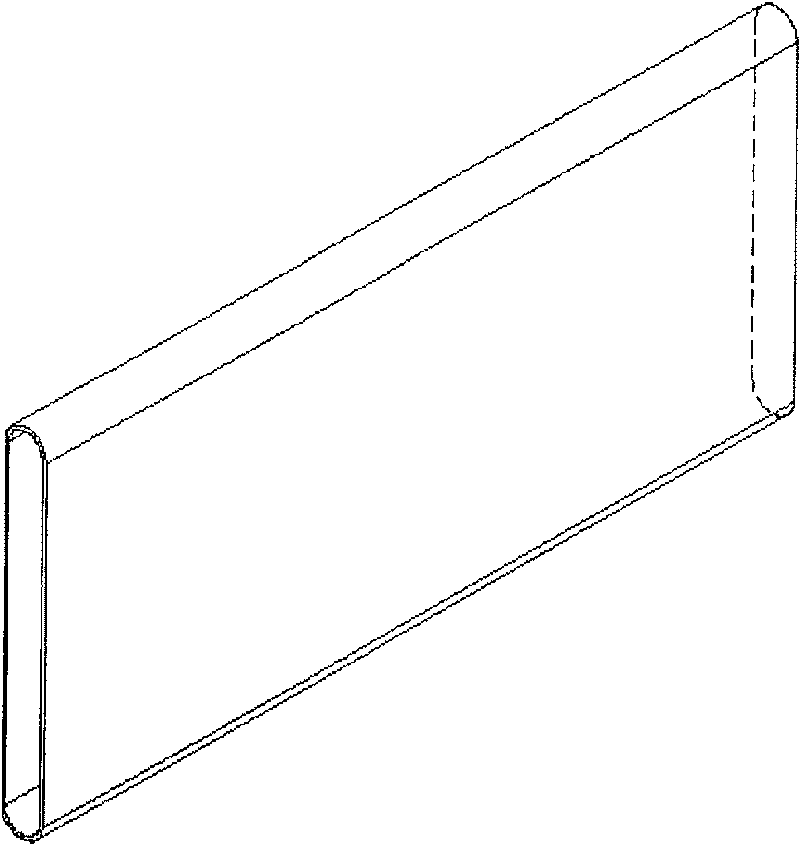

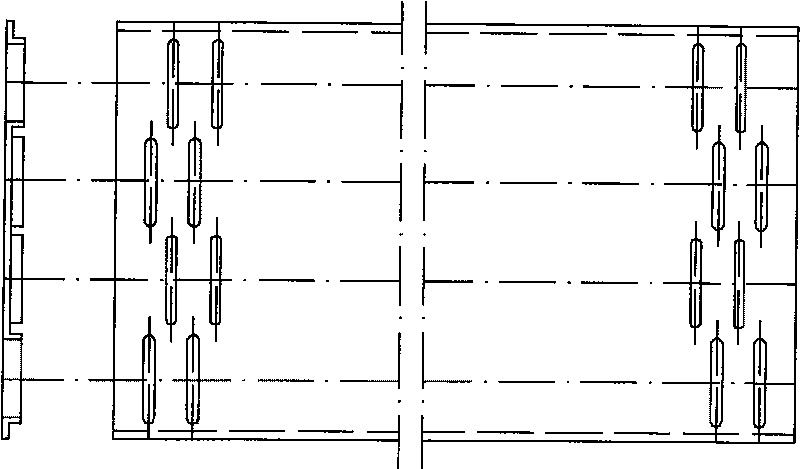

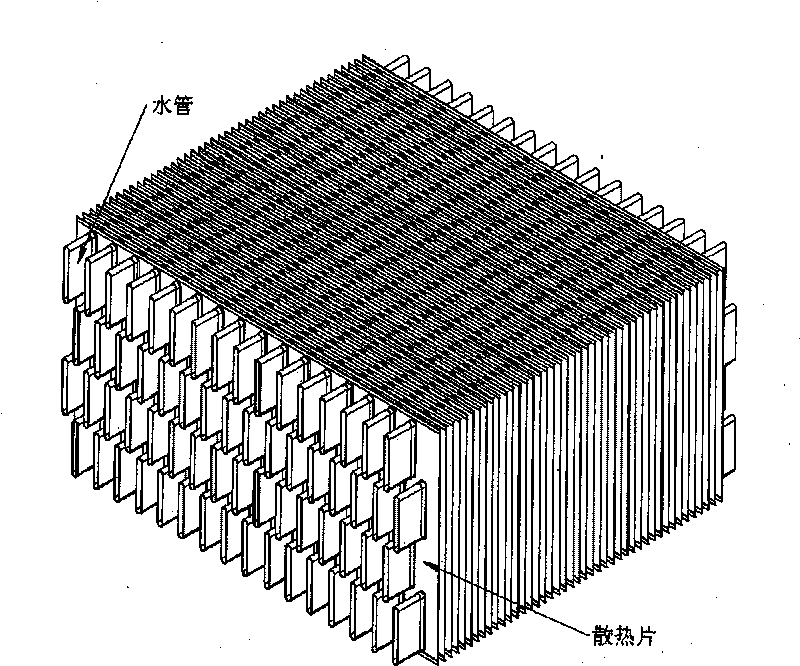

[0011] Such as Figure 4 As shown, the string core combination formwork is composed of a grille module I and a support module II, and adopts a combined structure. The grille module I is composed of a heat sink template 2, a spacer 6 and a clamping plate 7, and the heat sink template 2 is provided with a The conduit groove c2 corresponding to the heat sink 1 plays a guiding role when the water pipe is connected to the heat sink 1, and the core (see image 3 ) can move in the grille module 1 of the string-string composite formwork, the clamping plate 7 is provided with a conduit groove c4, and the conduit groove c4 is provided with a chamfer c3, and the conduit groove c4 plays a role when the water pipe is strung into the string-core composite template. As a guide, the chamfer c3 provided on the conduit groove c4 can correct the cross-sectional deformation of the water pipe, and the clamping plate 7 plays the role of clamping the heat sink formwork 2, improving the overall rigid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com