Automatic assembling device for lever handles of doors and windows

An assembly device and automatic technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, large volume, high price, etc., and achieve production cost saving, simple operation process, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

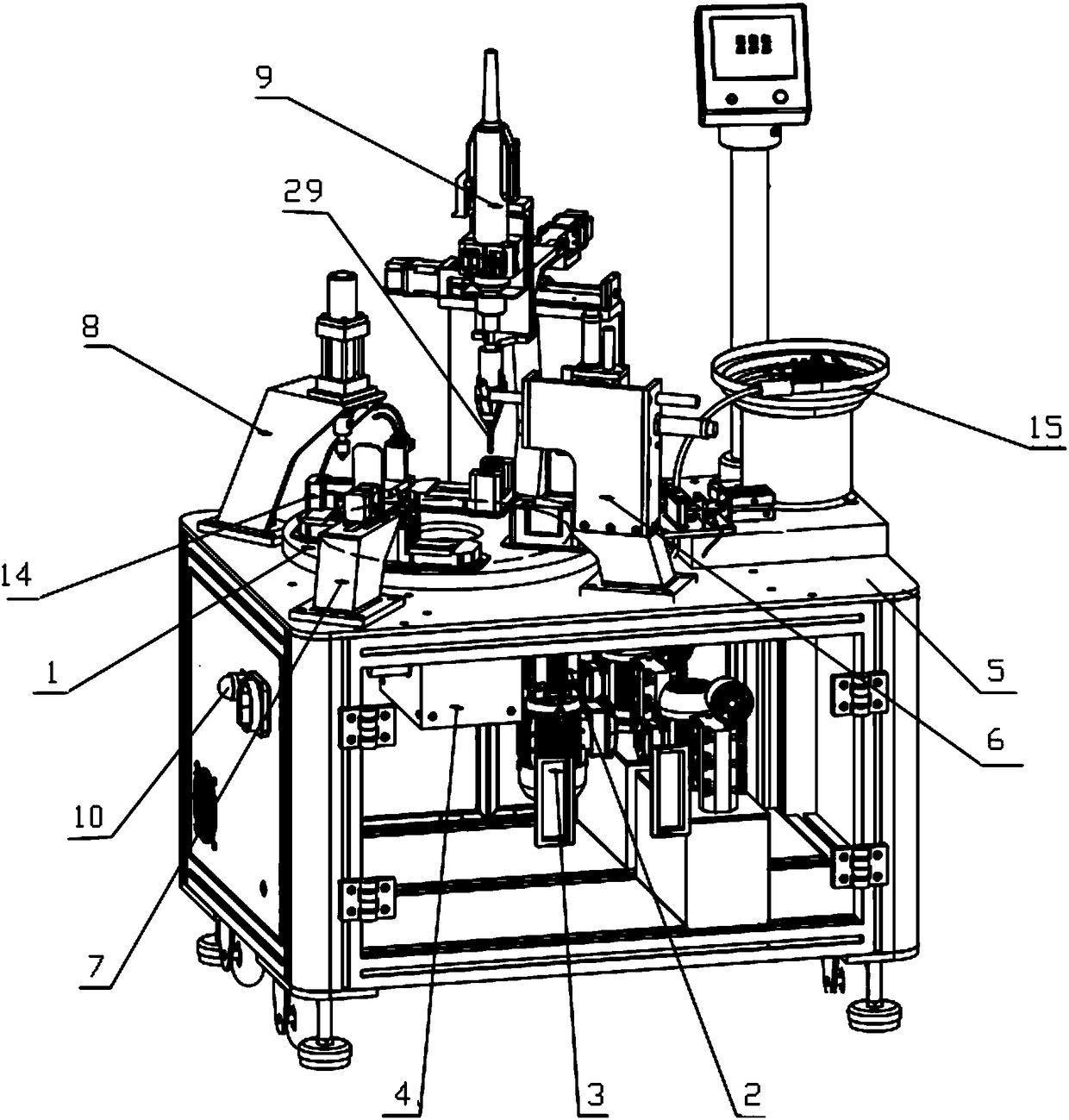

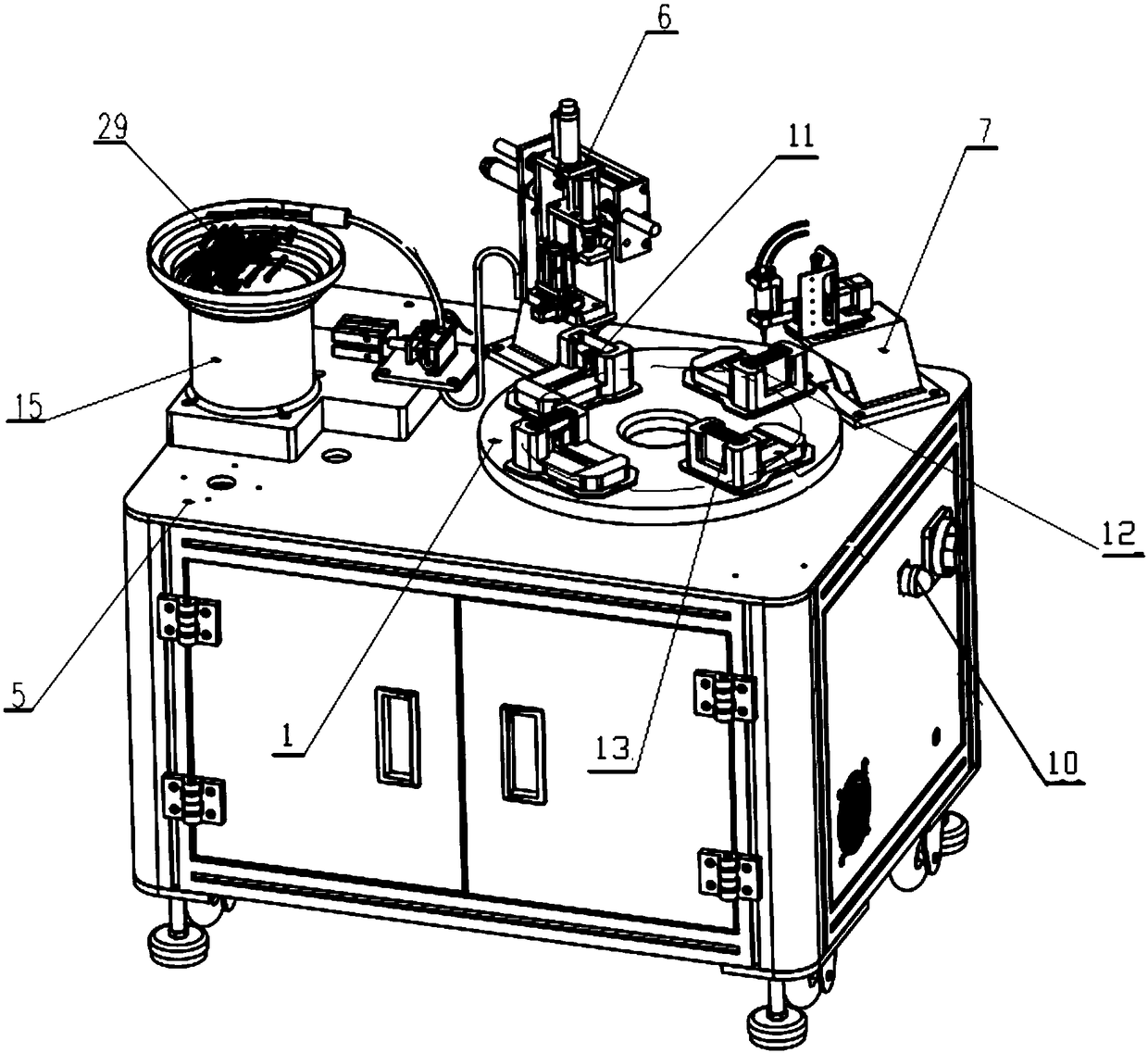

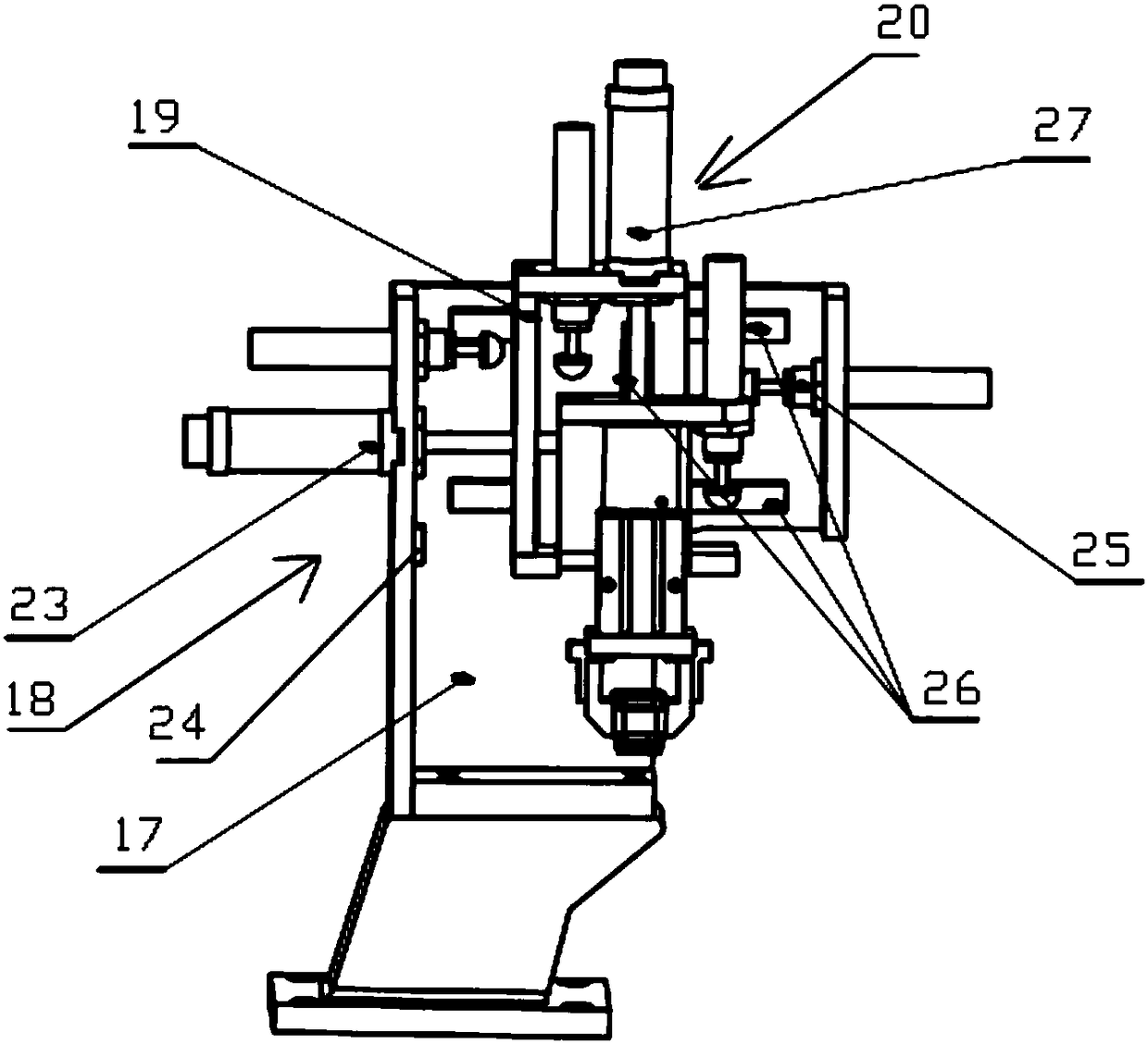

[0069] to combine figure 1 and figure 2 As shown, an automatic assembly device for door and window handles includes a workbench 5, a handle clamping device, a handle seat grabbing device 6, an automatic gluing device 7, an automatic oiling device 8 and an automatic screwing device 9.

[0070] The assembly of the handle is completed through the gripping device 6 of the handle seat, the automatic gluing device 7, the automatic oiling device 8 and the automatic screwing device 9 and manual cooperation, so as to reduce the fatigue strength of the labor force, improve production efficiency, and reduce the production cost of the enterprise .

[0071] The components and working process of the door and window handle automatic assembly device in this embodiment are described in detail below:

[0072] like figure 1 and figure 2 As shown, the handle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com