Wedge-shaped telescopic flow guide device for leachate from garbage storage bin

A diversion device, telescopic technology, applied in the field of leachate diversion devices of wedge-shaped telescopic garbage storage bins, can solve the problems of increasing the difficulty and cost of concrete structure treatment, the harsh environment for operators, frequent manual operations, etc. It achieves the effects of facilitating processing, good flushing and anti-blocking effects, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

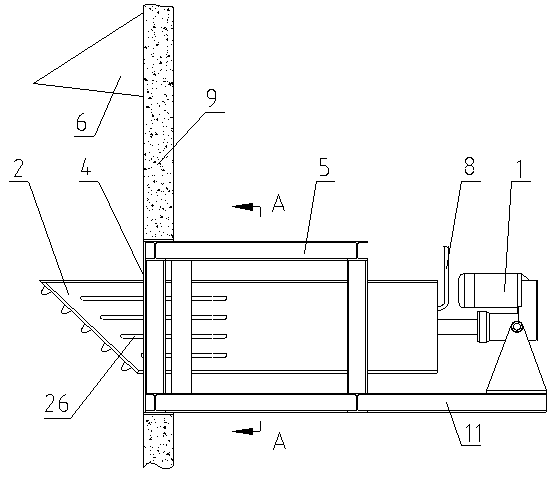

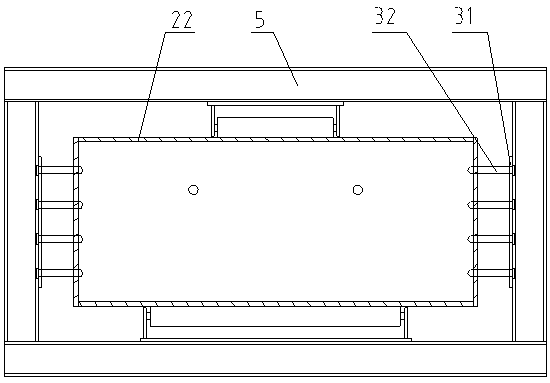

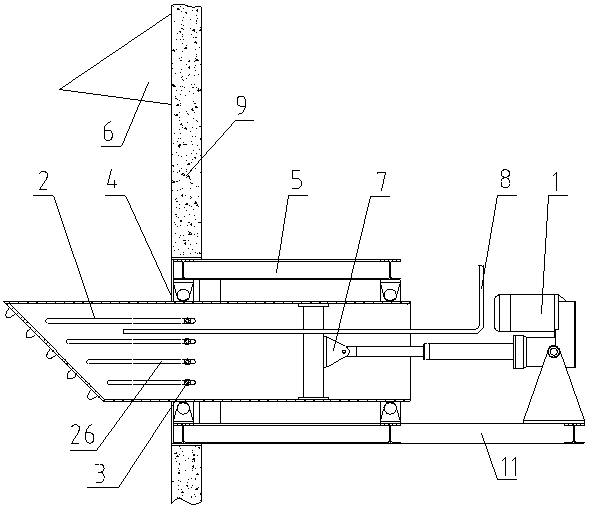

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] Please see attached figure 1 And attached image 3 , a leachate diversion device of a wedge-shaped telescopic garbage silo, including a telescopic transmission assembly, a wedge-shaped cutter head cylinder assembly 2, a piercing needle disk assembly 3, a sealing baffle 4, a base 5 and a water spray system 8; please Participate in Figure 4 And attached Figure 5 , the wedge-shaped cutter head cylinder assembly 2 includes a blade 21, a wedge-shaped flat cylinder 22, a support rod 23, a diversion hole 25 and a diversion groove 26, and the wedge-shaped flat cylinder 22 is a flat cylindrical structure with a rectangular cross section. The height of the cylinder is reduced under the material area, so that its flat structure can adapt to the installation arrangement in low, narrow and long applications, and the inner end of the wedge-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com