LED display module detection device

A display module and detection equipment technology, applied in the direction of static indicators, instruments, etc., can solve the problem of difficulty in adapting to the needs of rapid mass production, the inability to judge the uniformity of LED light panels, the difference in brightness and chromaticity between LED light panels and LED light panels, artificial Low detection efficiency and other problems, to achieve the effect of shortening the height of the equipment, saving labor costs, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

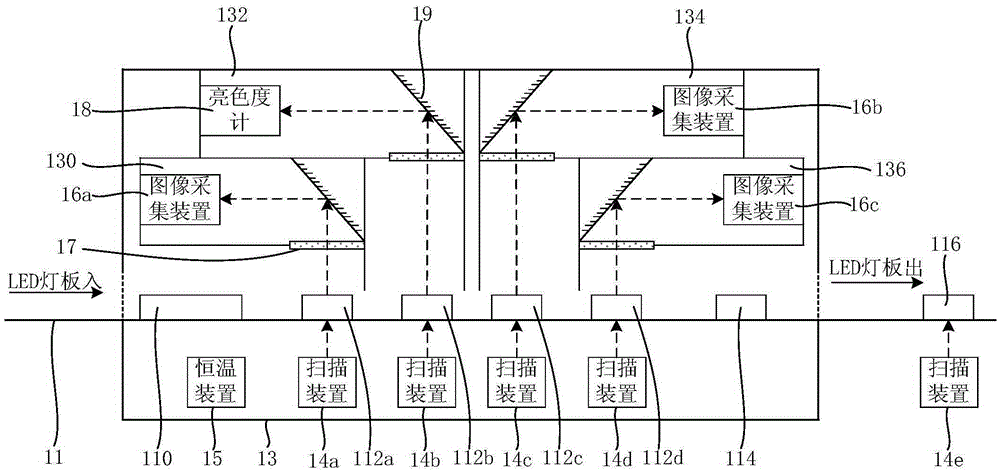

[0025] see figure 1 , The LED display module testing equipment proposed in the first embodiment of the present invention includes: a conveyor track system 11, a testing room 13, image testing chambers 130, 132, 134, 136, and scanning devices 14a-14e; and preferably also includes a constant temperature device 15.

[0026] Among them, the conveying track system 11 can transport and fix LED display modules such as LED lamp panels to designated locations, and its rails (such as conveyor belts) are equipped with automatic power-on and signal-on devices to ensure that the LED display modules arrive at designated locations and work normally. . It can be understood that, in addition to the track, the conveying track system 11 is typically also provided with a PLC (Programmable Logic Controller, programmable logic controller). Furthermore, from figure 1 It can be known that the transport track system 11 is configured with a pre-inspection waiting position 110 , image detection positi...

no. 2 example

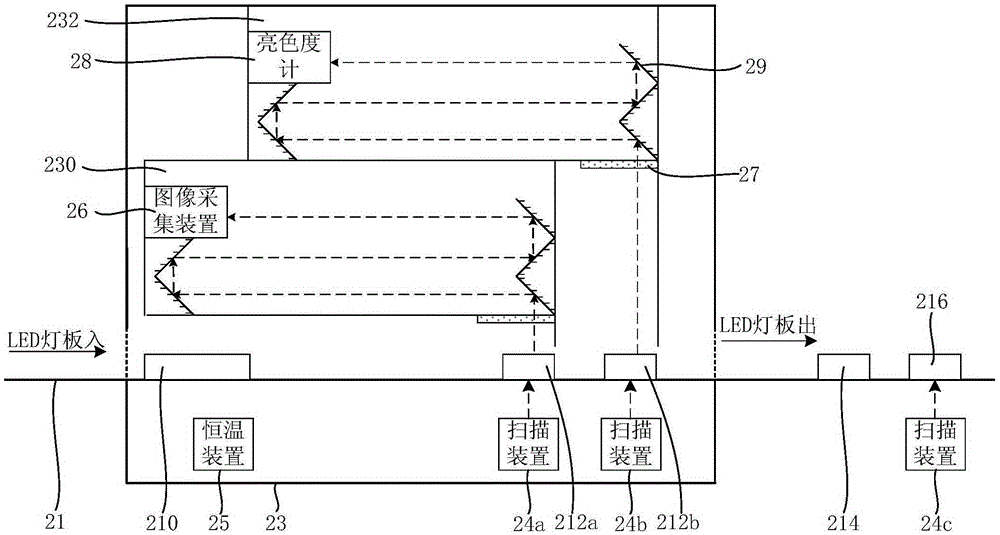

[0044] see figure 2 , The LED display module testing equipment proposed in the second embodiment of the present invention includes: a conveyor track system 21 , a testing room 23 , image testing chambers 230 , 232 , and scanning devices 24 a - 24 c ; and preferably also includes a constant temperature device 25 .

[0045] Among them, the conveying track system 21 can transport and fix LED display modules such as LED light boards to designated locations, and its rails (such as conveyor belts) are equipped with automatic power-on and signal-on devices to ensure that the LED display modules arrive at designated locations and work normally. . It can be understood that, in addition to the track, the conveying track system 21 is typically also provided with a PLC (Programmable Logic Controller, Programmable Logic Controller). Furthermore, from figure 2 It can be known that the transport track system 21 is configured with a pre-inspection waiting position 210 , image detection po...

no. 3 example

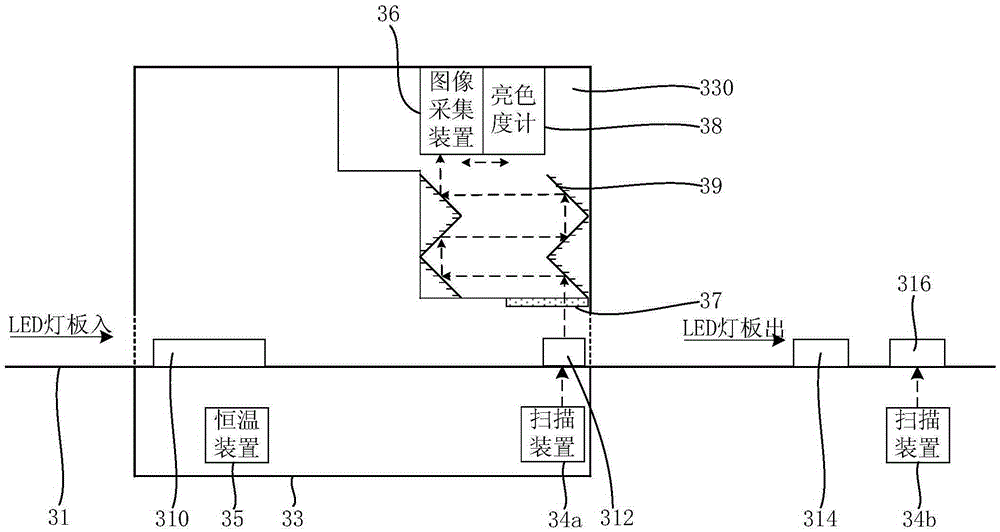

[0056] see image 3 , The LED display module inspection equipment proposed by the third embodiment of the present invention includes: a conveying track system 31 , an inspection chamber 33 , an image inspection chamber 330 , and scanning devices 34a, 34b; and preferably also includes a constant temperature device 25 .

[0057] Among them, the transmission track system 31 can transport and fix LED display modules such as LED lamp panels to designated positions, and its track (such as a conveyor belt) is equipped with automatic power-on and signal-on devices to ensure that the LED display modules arrive at designated positions and work normally. . It can be understood that, in addition to the track, the conveying track system 31 is typically also provided with a PLC (Programmable Logic Controller, programmable logic controller). Furthermore, from image 3 It can be known that the transport track system 31 is configured with a pre-inspection waiting position 310 , an image dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com